Patents

Literature

32results about How to "Guaranteed normal dumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

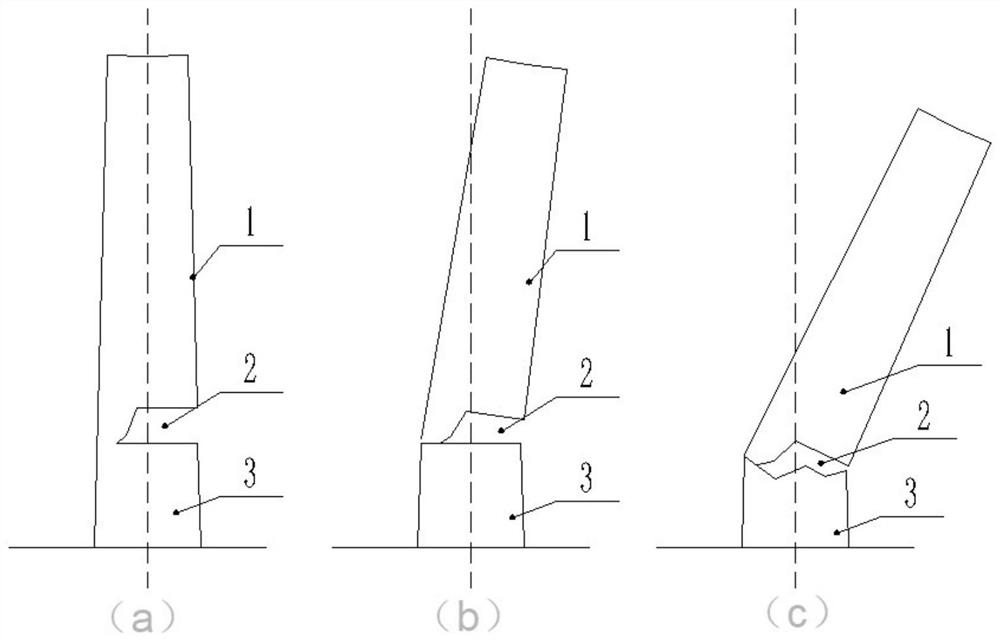

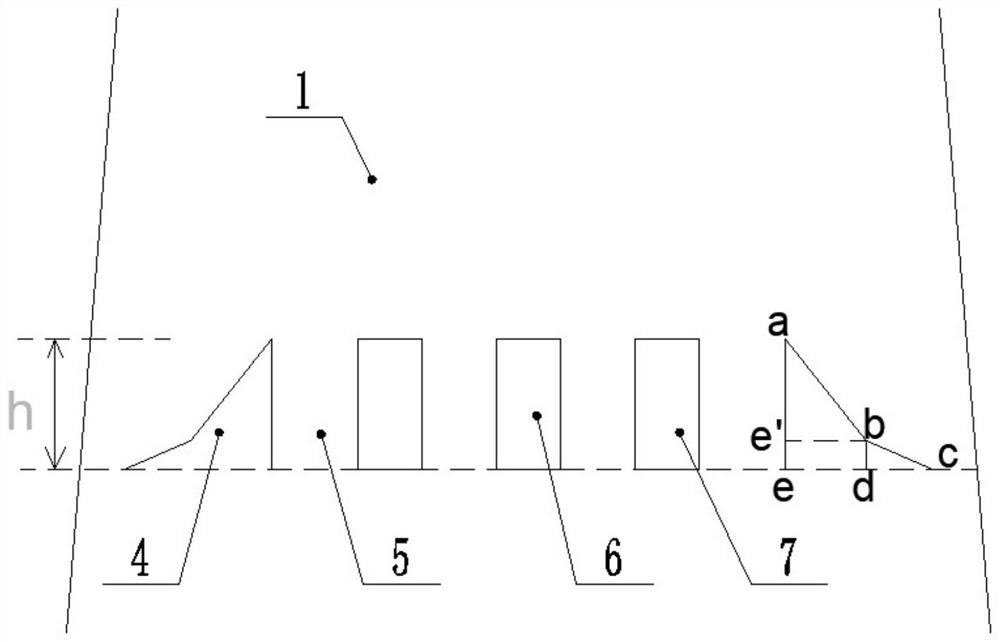

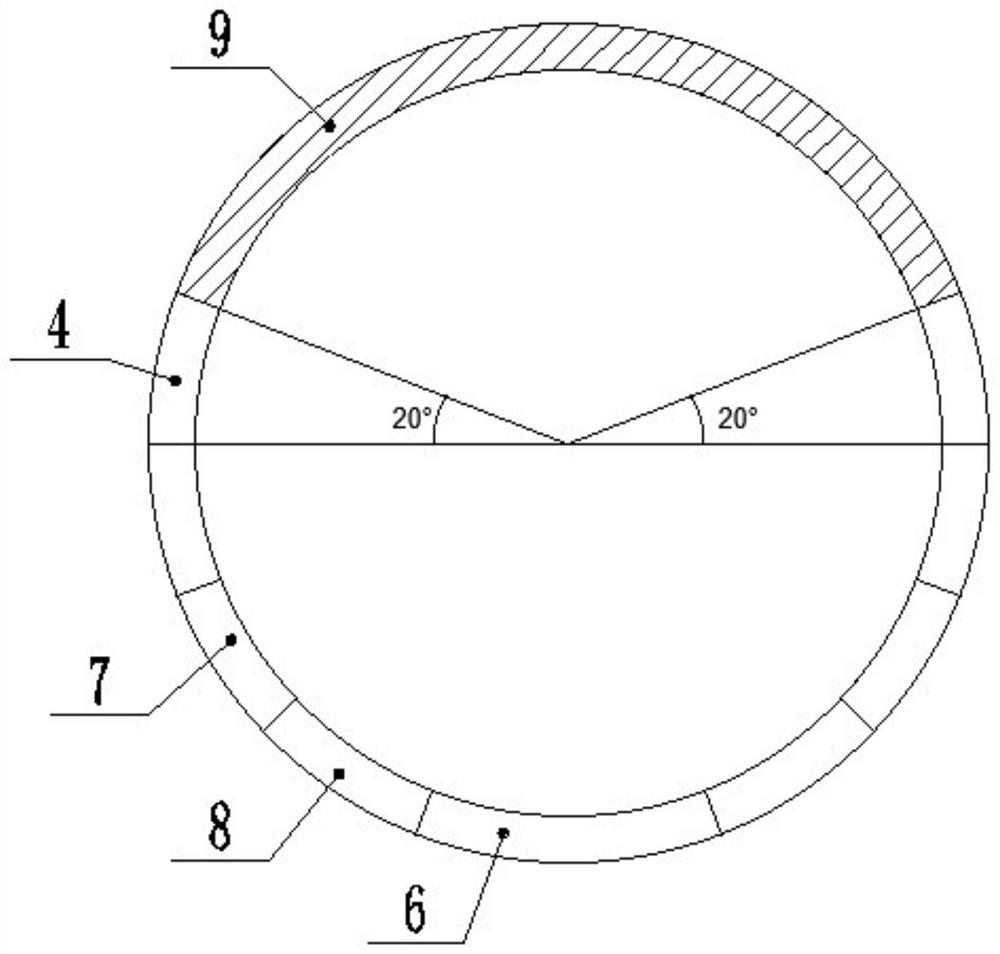

Method for high-notch blasting demolition of thin-wall reinforced concrete chimney

ActiveCN113279622AControl pouring direction and pouring angleSymmetrical and uniform forceBuilding repairsBlastingReinforced concreteArchitectural engineering

The invention relates to the technical field of engineering blasting, in particular to a method for the high-notch blasting demolition of a thin-wall reinforced concrete chimney. The method includes the steps of step 1, determining the collapse direction of the chimney and notch parameters according to the surrounding environment of the chimney, the height of the chimney and a chimney flue; step 2, pretreating a notch; step 3, forming a directional window and a positioning hole; step 4, forming a shot hole in a position where the notch is formed, and conducting charging to set a detonating network; and step 5, blasting the chimney. According to the method for the high-notch blasting demolition of the thin-wall reinforced concrete chimney, a high-position notch mode is used, an upper barrel body is lowered in the dumping process, a lower barrel body is dismantled through gravity, and the dumping coverage range of the whole chimney can be effectively reduced; and when the method is used in construction, the two initial closing angles of the high-notch are accurately controlled to be the same in size by adopting a mode of drilling by a hollow drill, so that the chimney is stressed uniformly and symmetrically, and the controllability of the dumping direction of the chimney is improved.

Owner:NUCLEAR IND NANJING CONSTR GRP CO LTD +1

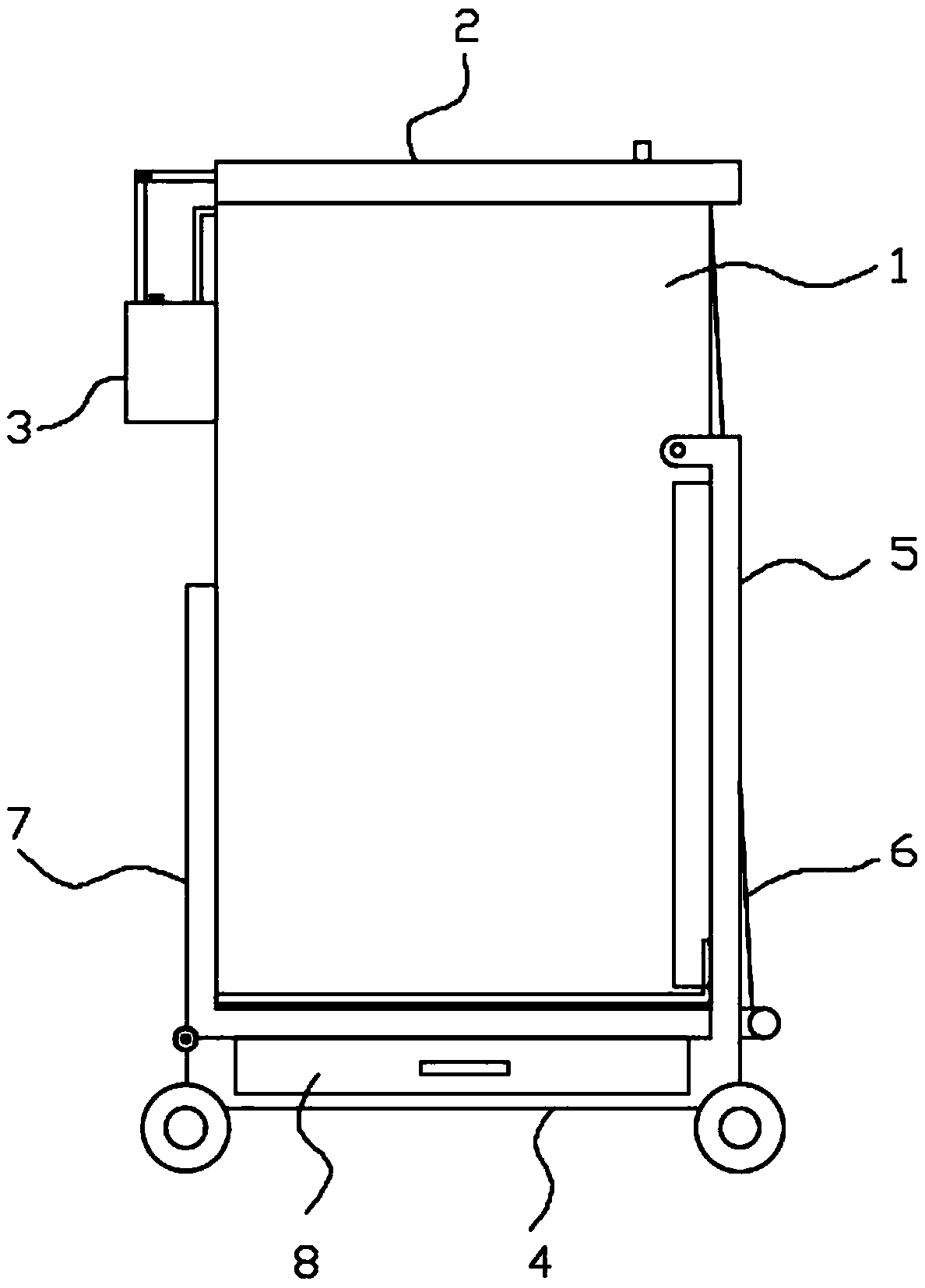

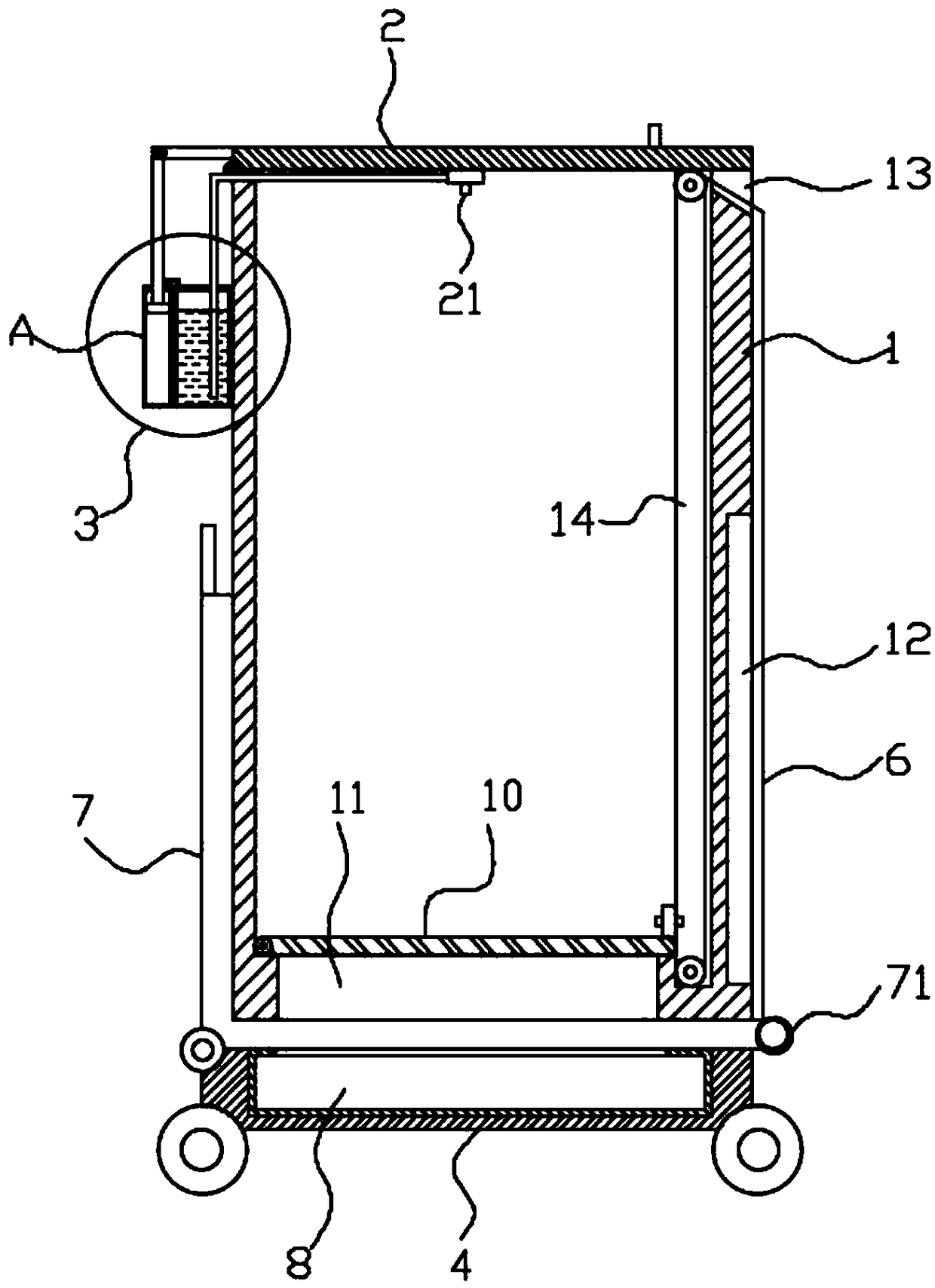

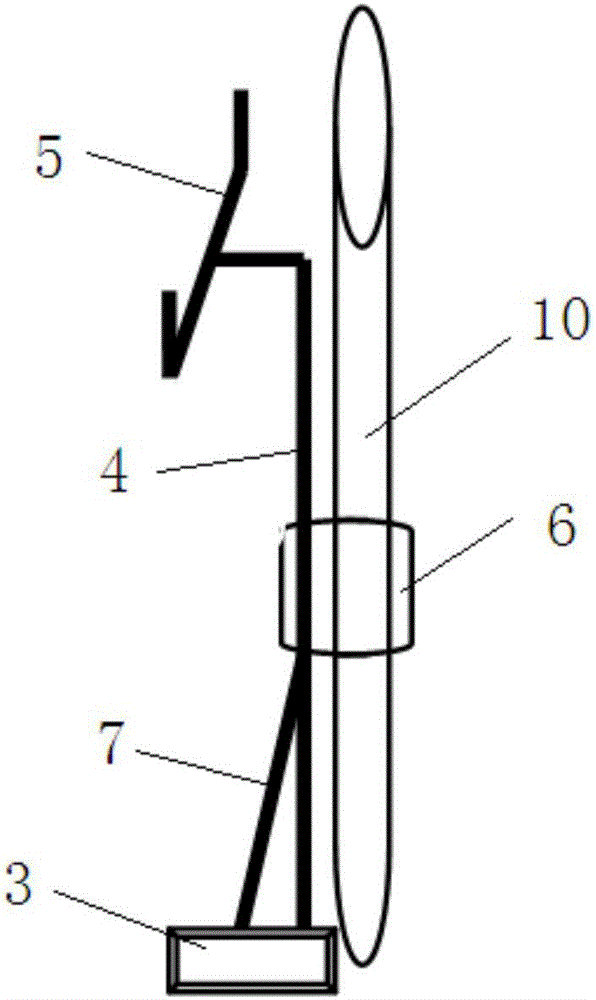

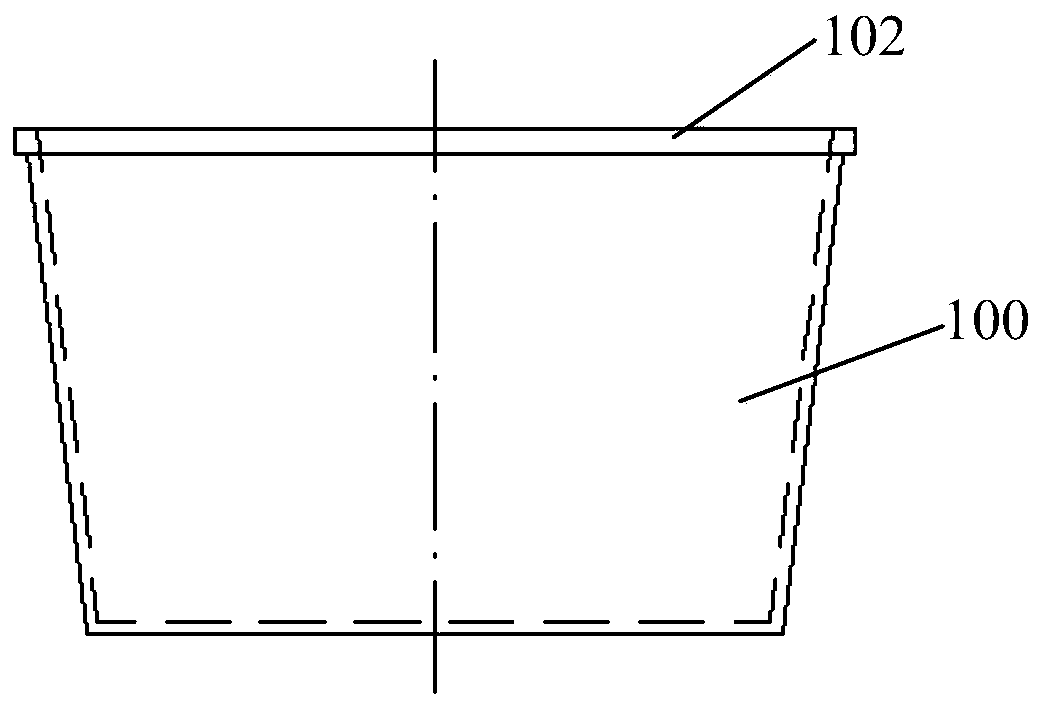

Automatic deodorization and easy-to-dump garbage can device for garbage treatment

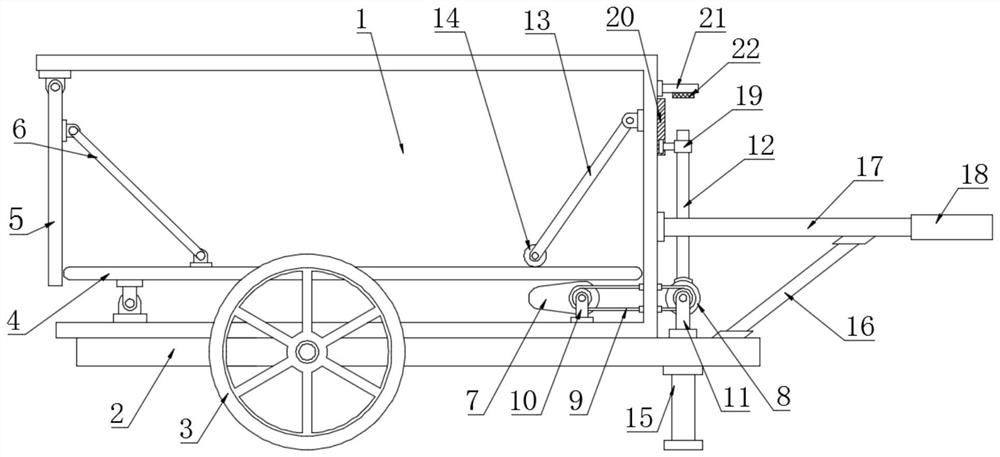

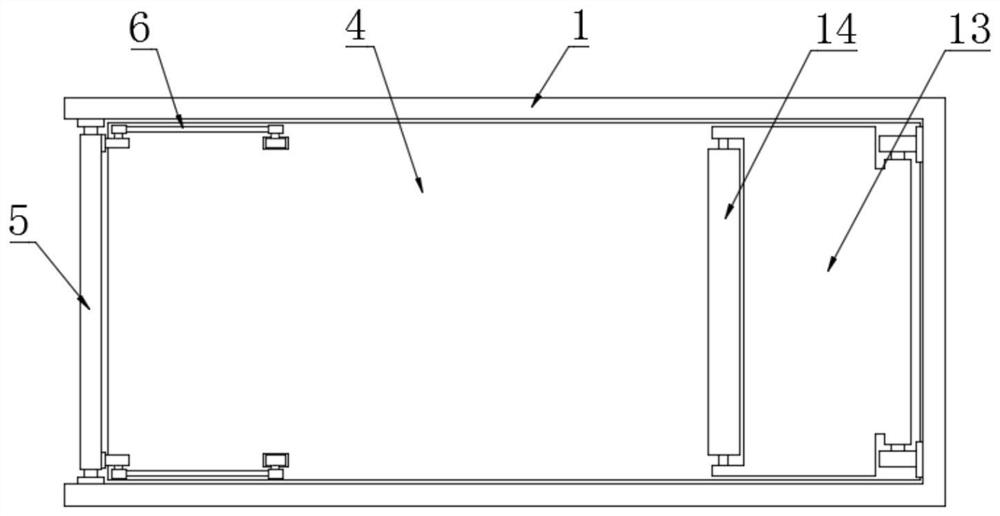

The invention discloses an automatic deodorization and easy-to-dump garbage can device for garbage treatment. The garbage can device comprises a base with rolling wheels, and supporting rods are arranged on the two sides of one end of the base; the two sides of a box body are hinged between the supporting rods; a turnover frame is hinged to the other end of the base; the turnover frame is of an L-shaped support structure wholly, a handrail rod is formed at the upper end of the turnover frame, the handrail rod is located on one side of the box body, and a roller used for supporting the box bodyis arranged at the end head of the bottom of the turnover frame; the roller is located on the other side of the box body; a movable bottom plate capable of ascending and descending is arranged in thebox body, a conveyor belt is vertically arranged on the inner wall of the box body, and one side of the movable bottom plate is connected with the conveyor belt; the upper end of the conveyor belt isconnected with a steel wire rope, and the steel wire rope extends out of the end port of the box body to be connected with the end head of the bottom of the turnover frame; a deodorization box is arranged on the outer wall of the box body; and a spray head is arranged on the bottom surface of a flip cover of the box body and communicates with the deodorization box. According to the device, garbage can be conveniently dumped by a user, the garbage can be guaranteed to be completely poured out, meanwhile, the functions of deodorization and sewage removal are achieved, so that the living convenience of people is greatly improved.

Owner:桃江县博强再生资源有限公司

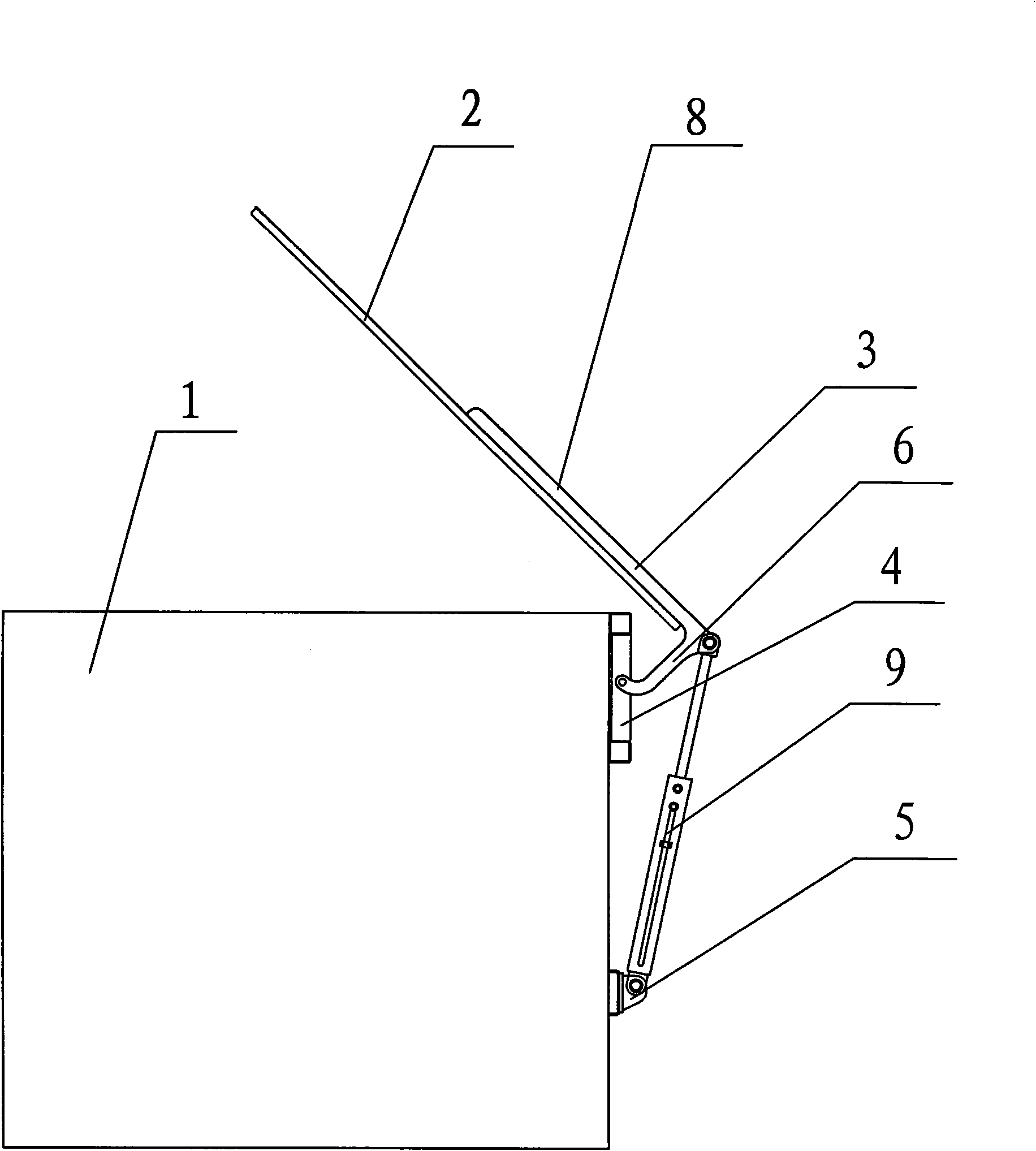

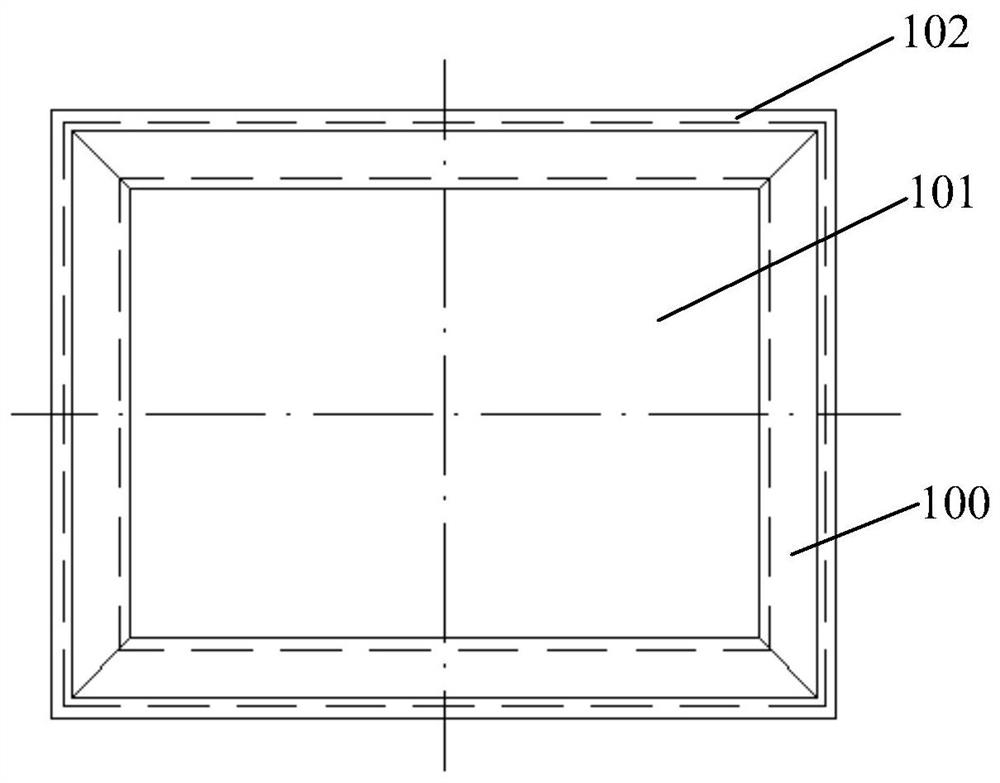

Single-side top cover lifting mechanism of rubbish transfer box

The invention discloses a single-side top cover lifting mechanism of a rubbish transfer box, and relates to a mechanism for opening the top cover of a box on a single side. The mechanism comprises a box and a top cover, two support seats are fixed at the upper part on one side of the box, an oil cylinder base is fixed at the lower part on one side of the box, wherein the support seats and the oil cylinder base are arranged on the same side of the box, a top cover revolving draw arm is arranged on one side of the box, the top cover revolving draw arm comprises a long arm and two short arms, a cross bar is arranged between two short arms, the upper ends of two short arms are connected with two ends of the cross bar respectively, the lower ends of two short arms are hinged on two support seats respectively, one end of the long arm is fixedly connected with the middle part of the cross bar, the long arm is fixedly connected with the top cover, and an extension cylinder is arranged between the oil cylinder base and the middle part of the cross bar. In the mechanism, the top cover revolving draw arm is driven by the up and down extension of the extension cylinder to rotate around the support base for closing and opening the top cover, and the range of the opening angle of the mechanism is 0 degrees to 127 degrees.

Owner:扬州市金威机械有限公司

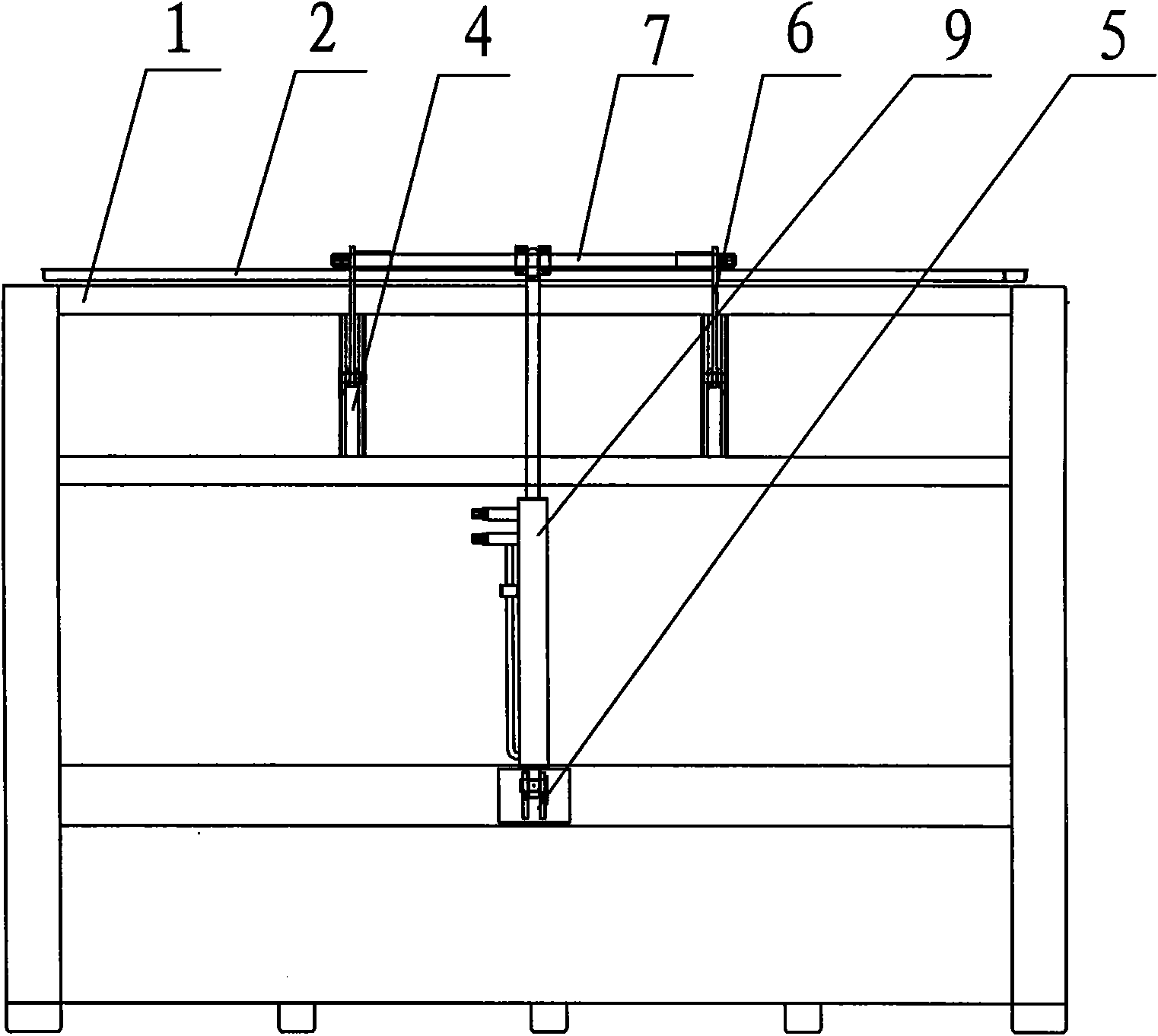

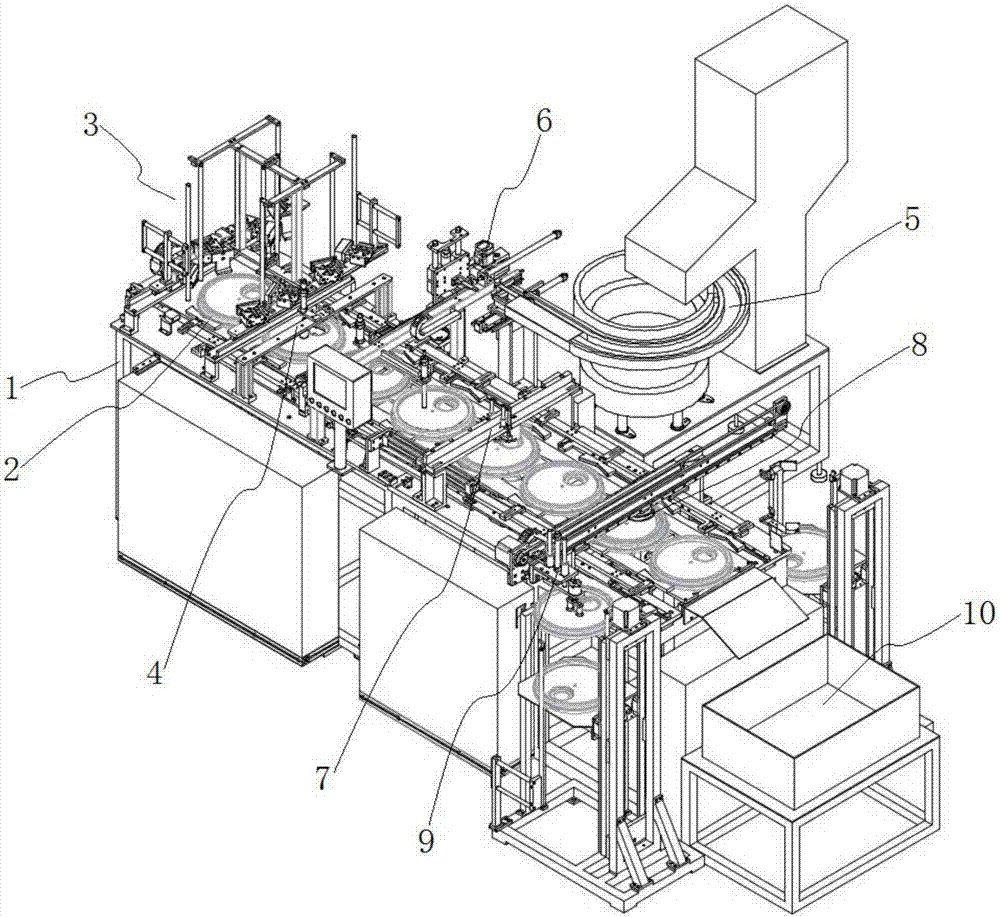

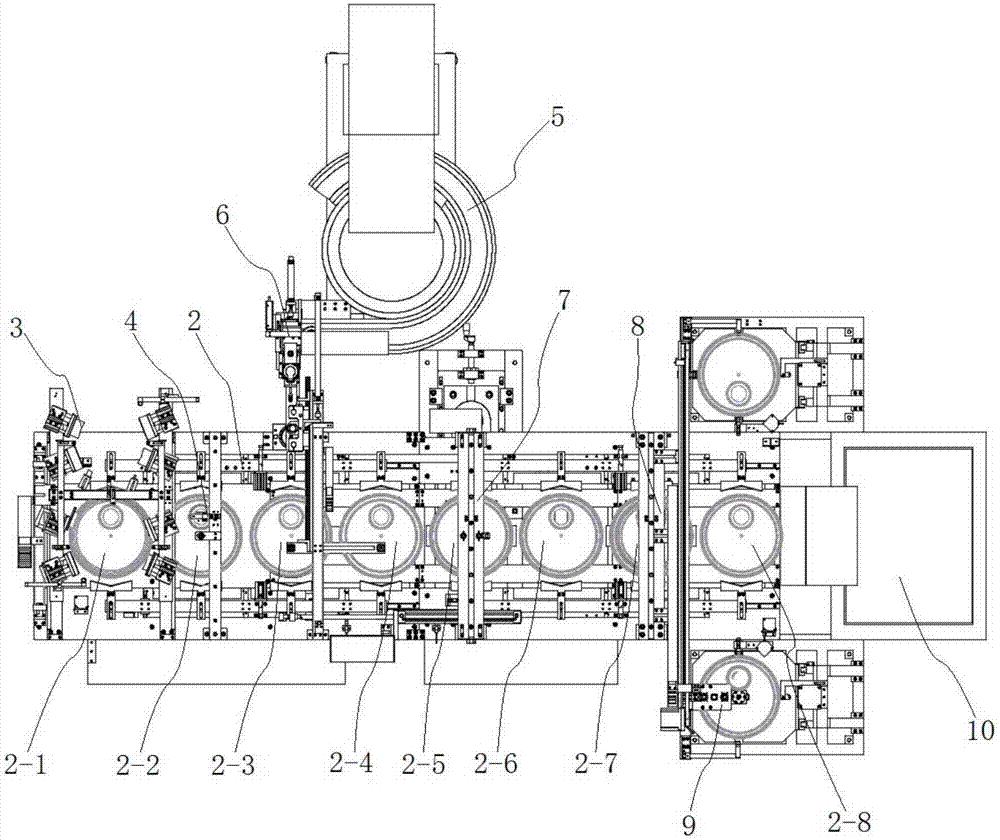

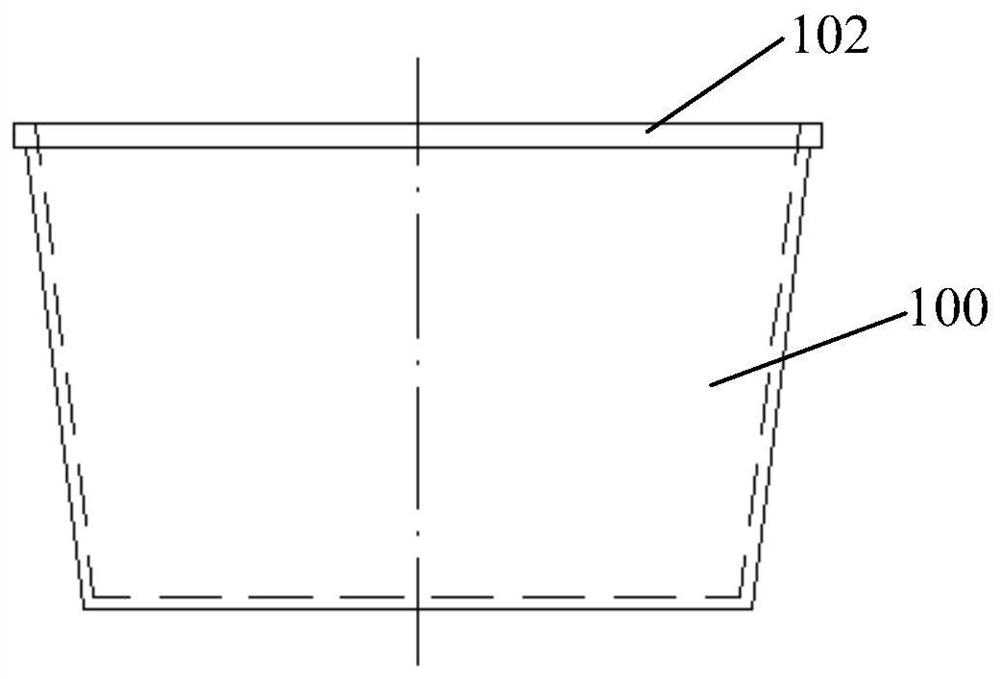

Automatic welding equipment for plastic barrel cover and oil nozzle

ActiveCN107139488ARealize continuous automatic welding productionCompact structureStacking articlesDe-stacking articlesUltrasonic weldingStructural engineering

The invention discloses automatic welding equipment for a plastic barrel cover and an oil nozzle and belongs to the field of automatic equipment. The automatic welding equipment disclosed by the invention comprises a frame and a barrel cover clamping and conveying device; a barrel cover feeding station, a barrel cover positioning station, an oil nozzle mounting station, a welding station, a detecting station and a discharging station are arranged in sequence on the barrel cover clamping and conveying device and along a rectilinear direction; a barrel cover feeding device is arranged at the barrel cover feeding station; a barrel cover rotary positioning device is arranged at the barrel cover positioning station; an oil nozzle positioning and mounting device is arranged at the oil nozzle mounting station; an ultrasonic welding device is arranged at the welding station; an air tightness detecting device is arranged at the detecting station; and a discharged material stacking device and an inferior-quality product recycling device are arranged at the discharging station. The automatic welding equipment disclosed by the invention can sequentially automatically accomplish the work of barrel cover feeding, barrel cover positioning, oil nozzle positioning and mounting, welding, air tightness detection and discharged material stacking, and is simple and compact in structure, stable and reliable in operation, flexible and convenient to control, high in production efficiency and good in welding quality.

Owner:CHANGZHOU CENTRWAY PLASTICS

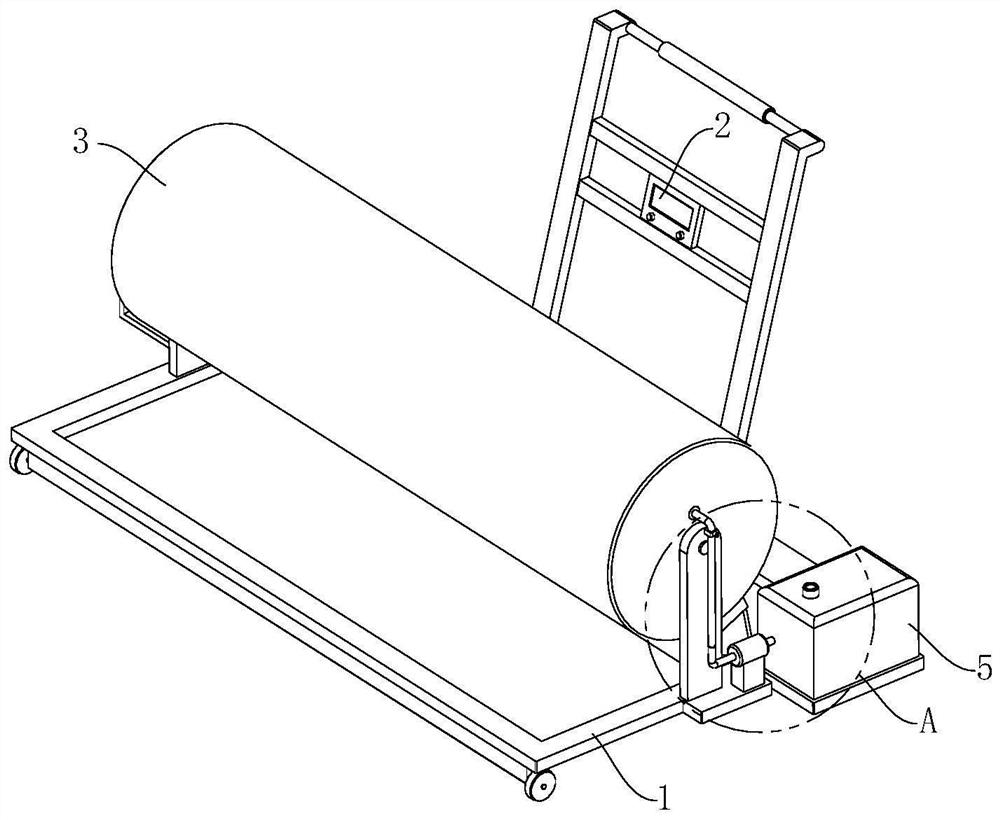

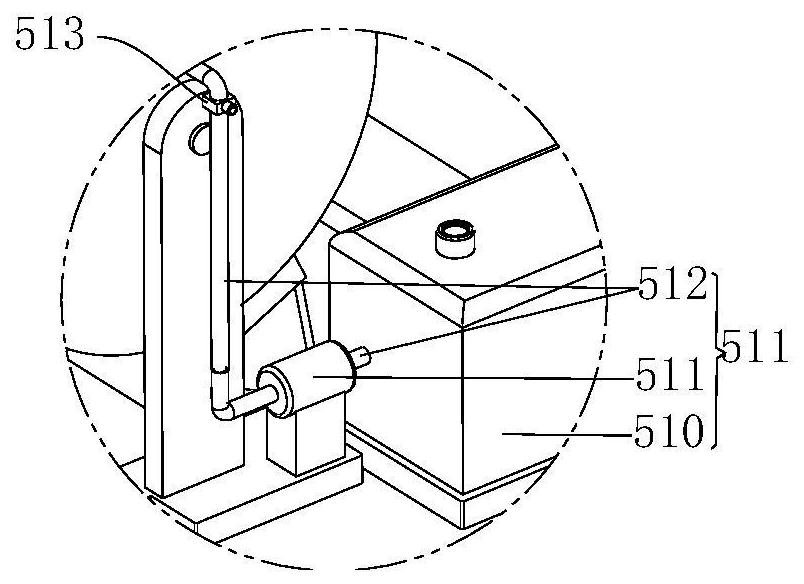

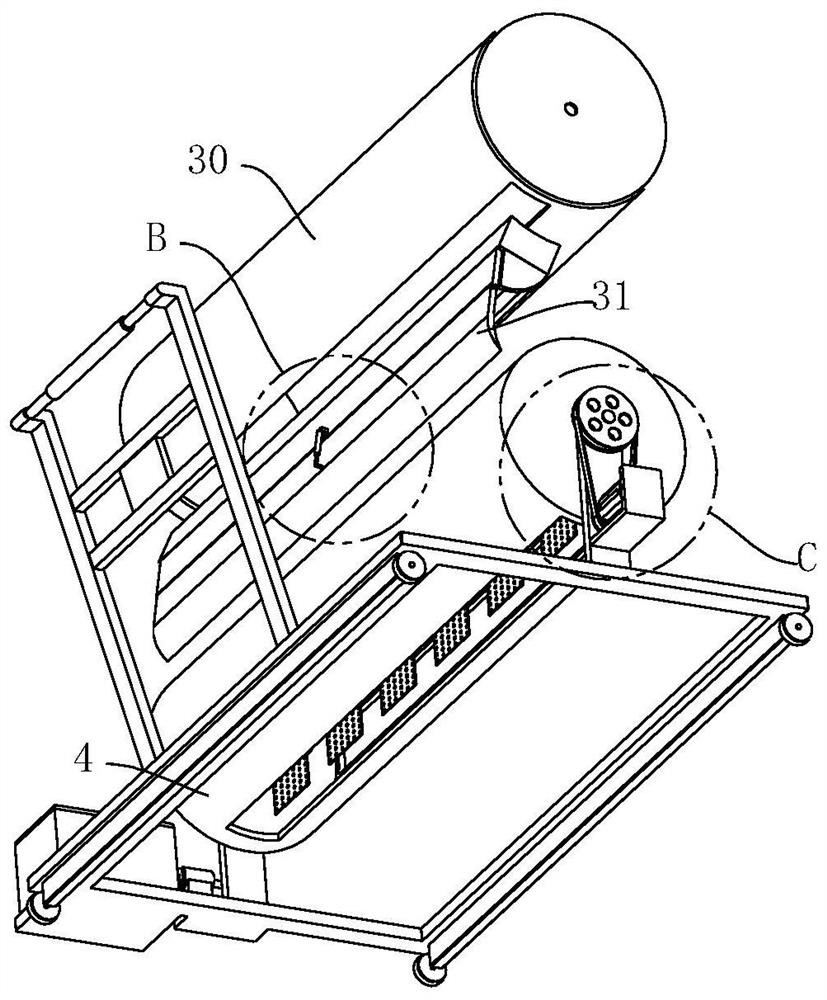

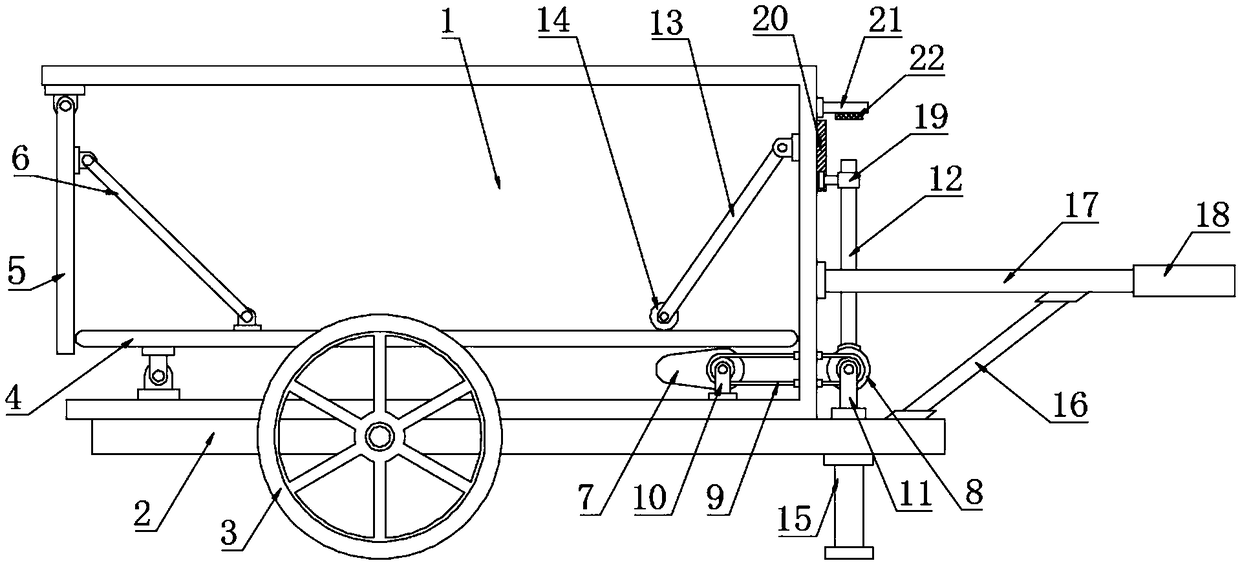

Liquid fertilizer applying device and method with soil turning and refilling functions

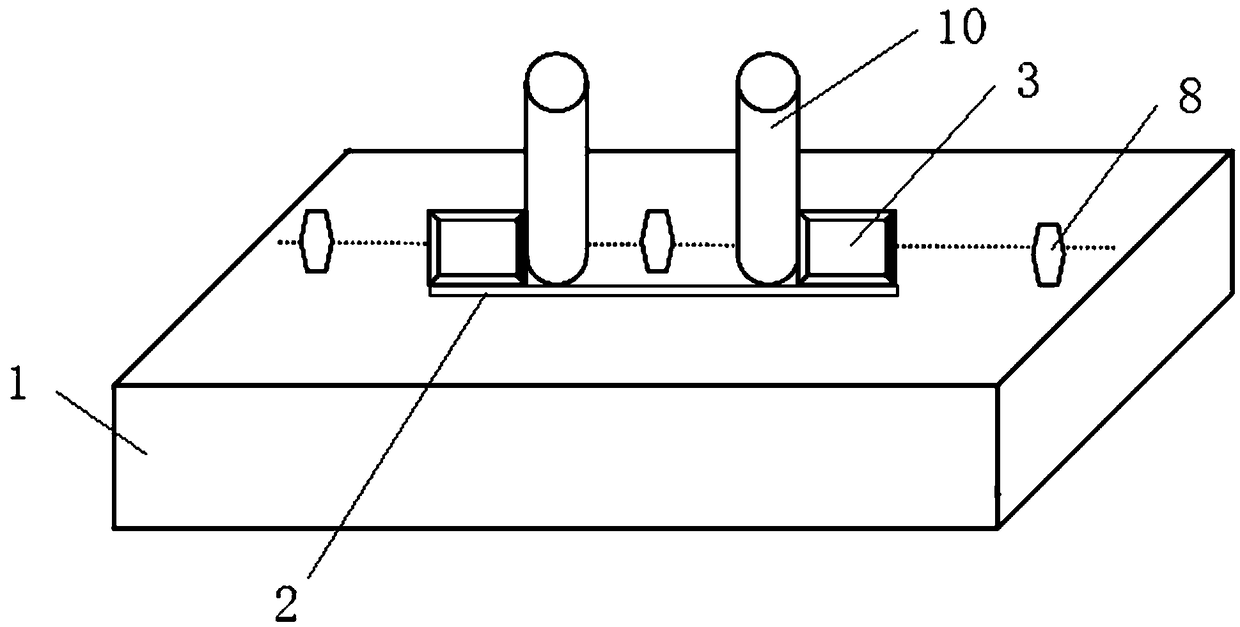

PendingCN113039887AEasy to slideImprove delivery efficiencySpadesLiquid fertiliser regulation systemsSoil scienceSoil mixing

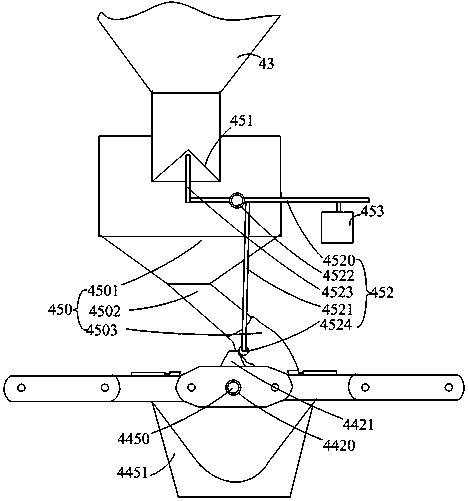

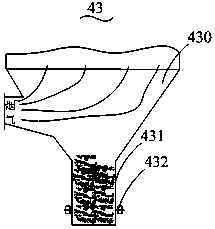

The invention relates to the field of agricultural machinery, in particular to a liquid fertilizer applying device and method with soil turning and refilling functions. The liquid fertilizer applying device comprises a flat cart, wherein a rectangular receding groove is formed in the flat cart, the liquid fertilizer applying device further comprises a controller, a digging and filling mechanism, a stirring mechanism and a spraying mechanism, the digging and filling mechanism comprises an outer cylinder, an arc-shaped digging plate and a rotating assembly, the stirring mechanism comprises an inner cylinder and a stirring assembly, the spraying mechanism comprises a conical containing box, a conveying assembly, an extrusion assembly and a plurality of atomization nozzles, and the rotating assembly and the conveying assembly are electrically connected with the controller. According to the liquid fertilizer applying device and method with the soil turning and refilling functions, liquid fertilizer can be uniformly mixed with soil, fertilizer application is more uniform, meanwhile, dug soil can be completely conveyed into the device, residues are prevented, the improvement of the soil turning efficiency is facilitated, the dug soil can be thoroughly refined, and the soil turning effect is improved.

Owner:张风浩

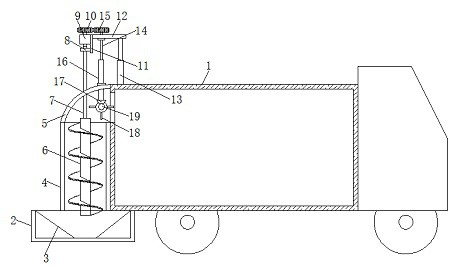

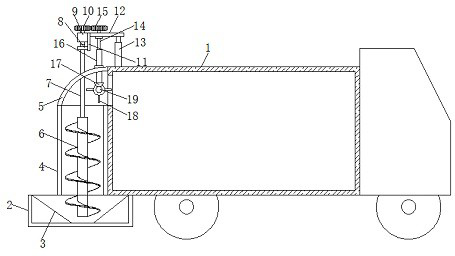

Garbage truck for municipal environmental sanitation cleaning

The invention discloses a garbage truck for municipal environmental sanitation cleaning. The garbage truck is characterized in that the upper part of a garbage can is opened, the bottom of the garbagecan is fixedly connected to a truck frame, the front part of the two sides of the truck frame are rotationally connected to side wheels in a bearing mode respectively, a driving wheel is arranged above the rear part of the truck frame, and the driving wheel is fixedly connected to the middle of the driving shaft; the upper part of the driving wheel is fixedly connected to a control rod, a cam isarranged behind the bottom of the garbage can, the cam is fixed to the center of a cam shaft, the two sides of the cam are provided with chain wheels respectively, and the chain wheels are fixedly connected to the cam shaft; the two sides of the driving wheel are also provided with chain wheels, and the chain wheels on the driving shaft and the two chain wheels on the cam shaft are correspondinglyconnected to each other through chains; a bottom plate is arranged below the garbage can, the lower surface of the front part of the bottom plate is hinged to the bottom of the garbage can, the lowersurface of the rear part of the bottom plate abuts against the cam, and a tail cover is arranged at the front part of the garbage can; and the upper end of the tail cover is rotationally connected tothe upper part of the front part of the garbage can, the two sides of the upper part of the tail cover are rotationally connected to the upper ends of connecting rods respectively, and the lower endsof the connecting rods are connected to the two sides of the bottom plate in a rotating mode.

Owner:HENAN YIXIANG SPECIAL VEHICLE

Garden shears capable of automatically collecting branches

The invention discloses garden shears capable of automatically collecting branches, and the garden shears comprise a shear blade, a fixed plate and a collecting bag, wherein the shear blade is in hinge joint with the fixed plate through rivets, in a closed position, the shear blade edge is in contact with the corresponding position of the fixed plate, and the collecting bag is connected with the shears. The garden shears have the advantages of automatically collecting plant tissues, reducing environmental pollution and saving manpower, simple structure and low cost.

Owner:张家港市星星工具制造有限公司

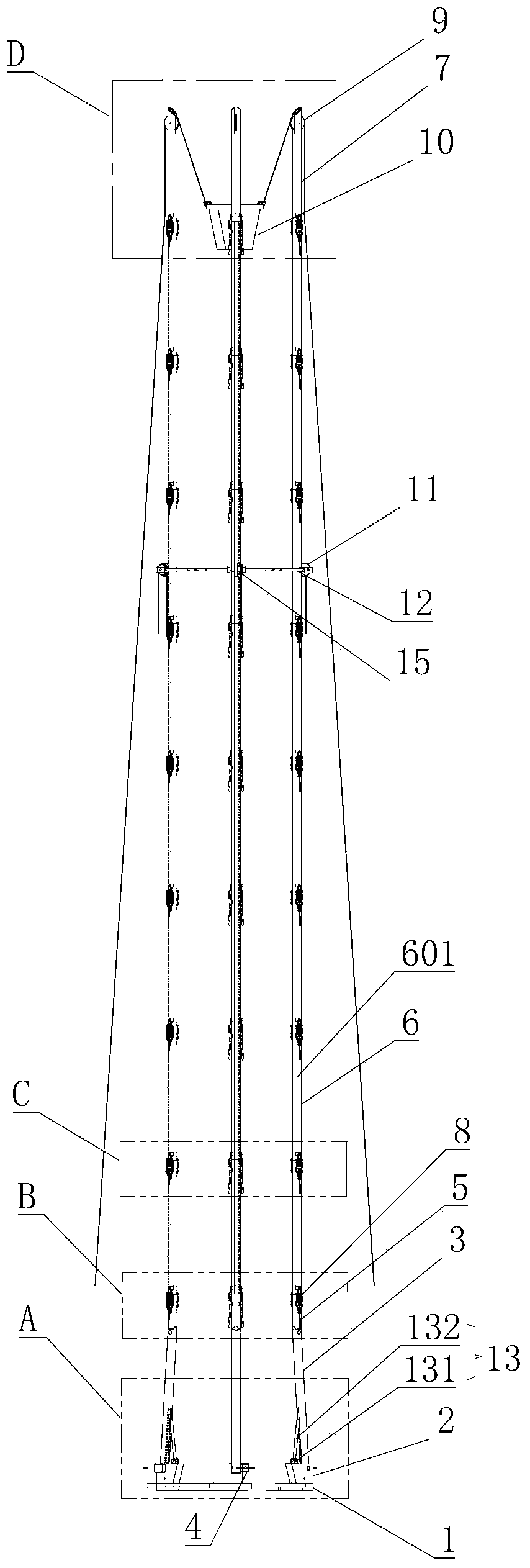

Reinforcing structure and method of double-cement tower in coal gob area

The invention discloses a reinforcing structure and method of a double-cement tower in a coal gob area and aims at reinforcing a double-cement tower, keeping a favorable reinforcing deviation rectifying effect, meeting the requirement for safety operation of a line, reaching the operation standard of the line, realizing in-advance precaution and prevention of hidden dangers and keeping safety production. The adopted technical scheme is as follows: a strip-shaped foundation is poured on a double-cement tower foundation and is used as a foundation to be reinforced, a planar steel plate is embedded in the strip-shaped foundation and is fixedly provided with a plurality of groups of channel steel clinging to a pole body of the double-cement tower, the channel steel is provided with upright column channel steel fixedly connected with the pole body of the double-cement tower, the pole body of the double-cement tower is reinforced by using the channel steel and the upright column channel steel, meanwhile, a cross arm of the double-cement tower is supported by a U-shaped clamping slot in the top of the upright column channel steel, an insulator string which is hung by using a vertical steel cored stranded wire is hung at the lower end of every phase conductor of the double-cement tower, and a length-adjustable 45-DEG bracing wire is connected to the double-cement tower.

Owner:STATE GRID CORP OF CHINA +1

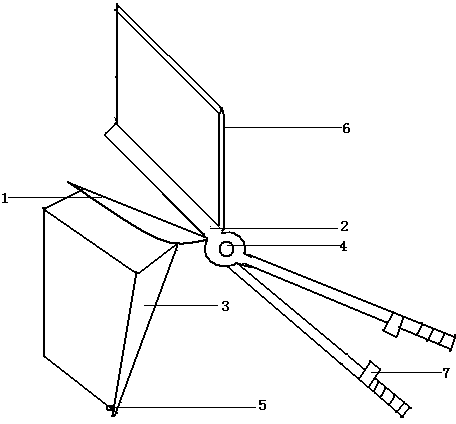

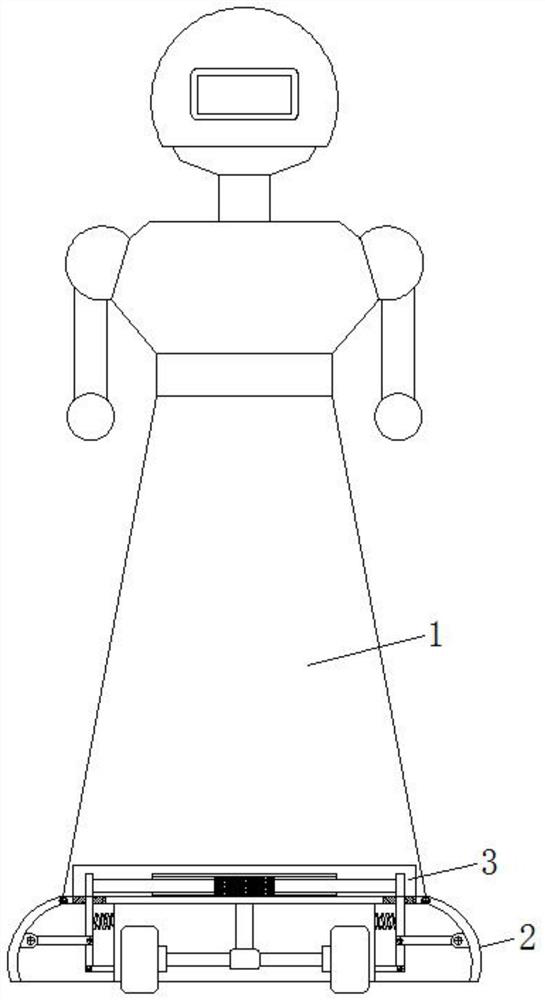

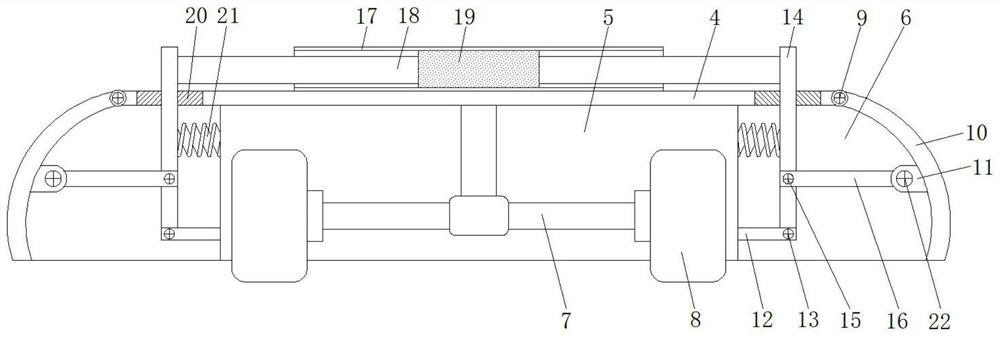

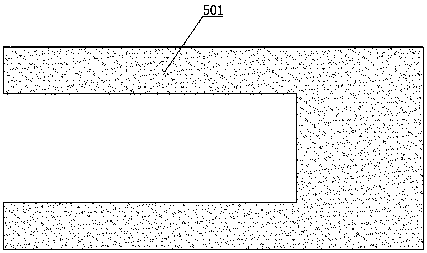

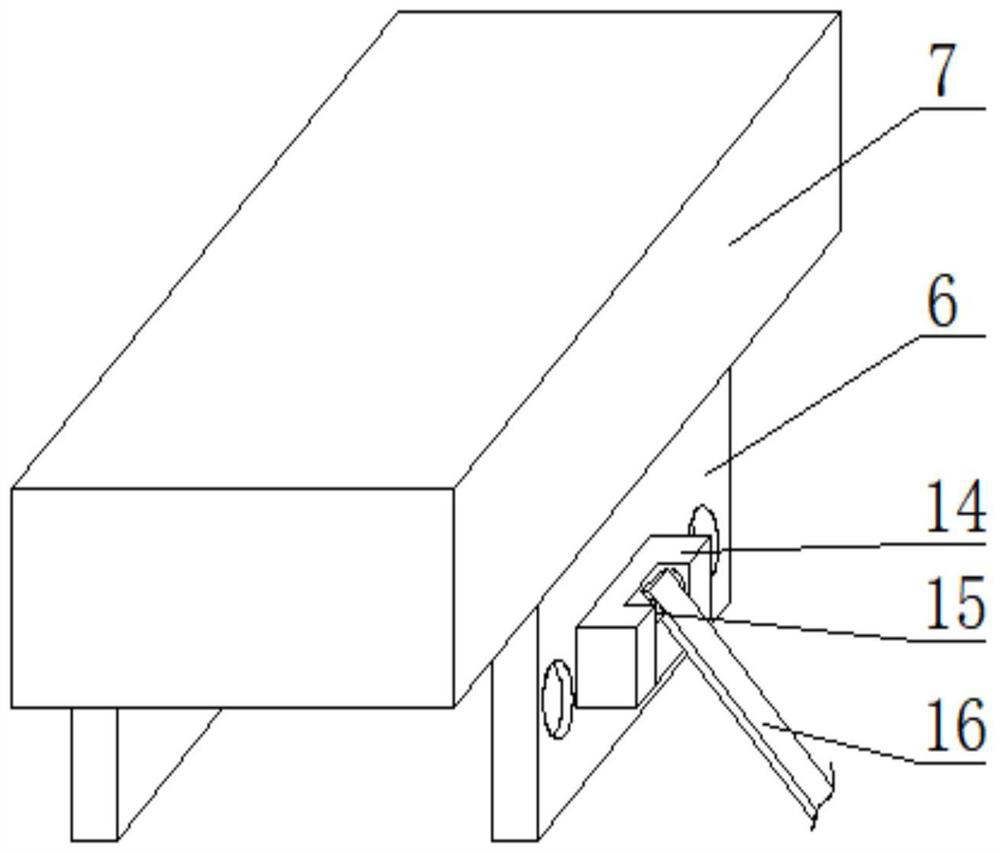

Anti-collision chassis for a service robot

ActiveCN112572642BGuaranteed normal dumpingPrevent dumpingVehicle body stabilisationBumpersDrive wheelDrive shaft

The invention discloses an anti-collision chassis for a service robot. An installation groove is opened through the bottom of the robot body, and an anti-collision base is arranged inside the installation groove. The top of the groove inner wall, the anti-collision base is composed of a top plate, a motion cavity, a balance cavity, a drive shaft and a drive wheel. The present invention can drive the robot body to move by arranging a movable anti-collision base, and the set counterweight can ensure that the robot body is toppled during the movement; if the robot body collides, first the anti-collision plate will Move along the first connecting pin, so that the third support rod and the second support rod can be pushed to move, so that the counterweight inside the balance tube can be moved to the other side that is hit, so that the counterweight can The inclined force generated by the moving balance collision can prevent the occurrence of dumping to a certain extent.

Owner:安徽新博普曼智能科技股份有限公司

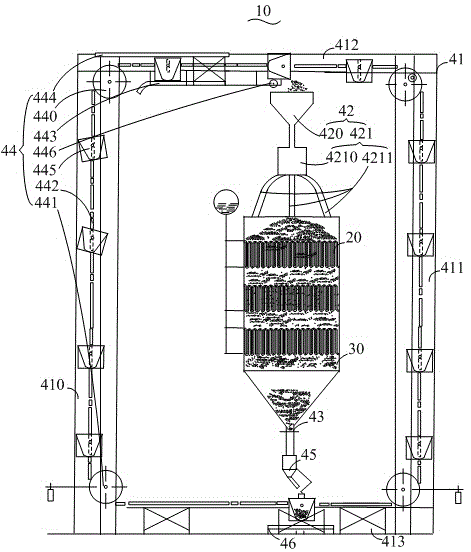

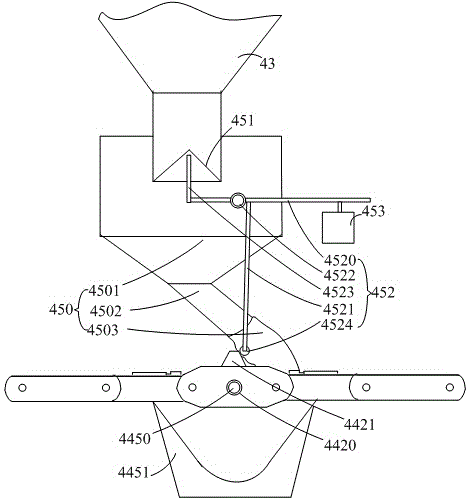

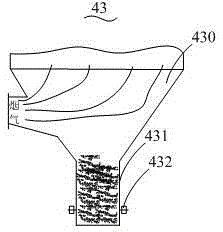

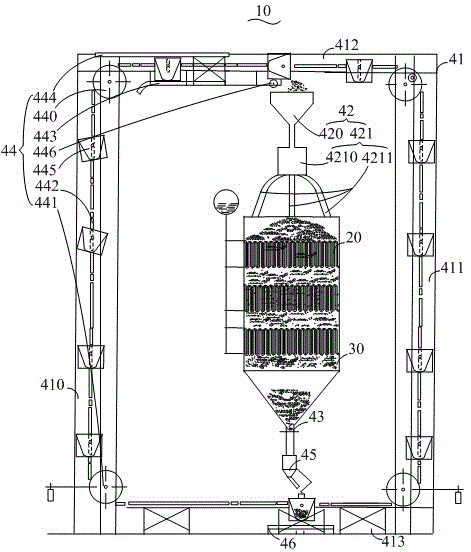

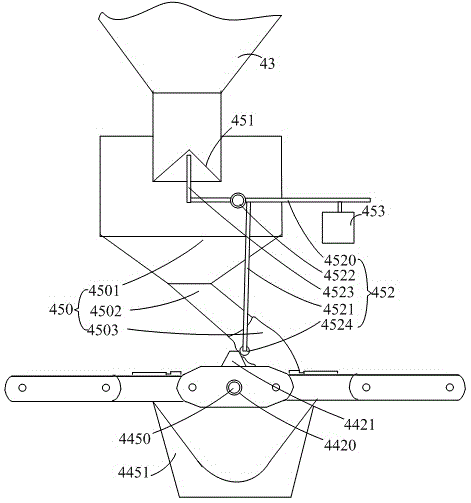

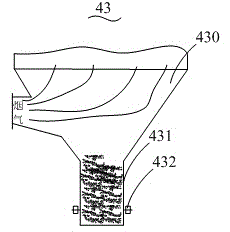

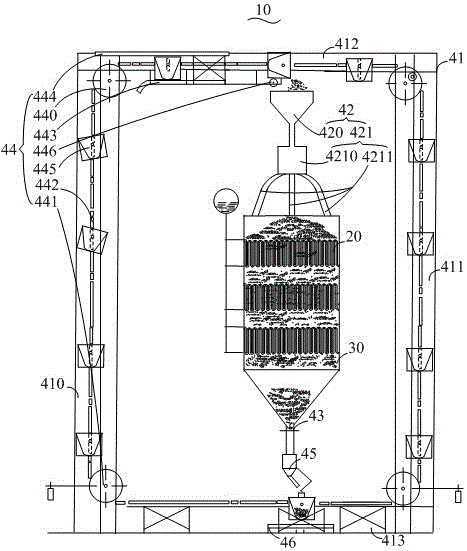

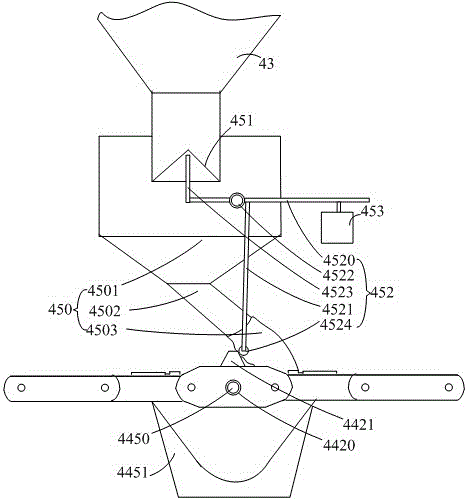

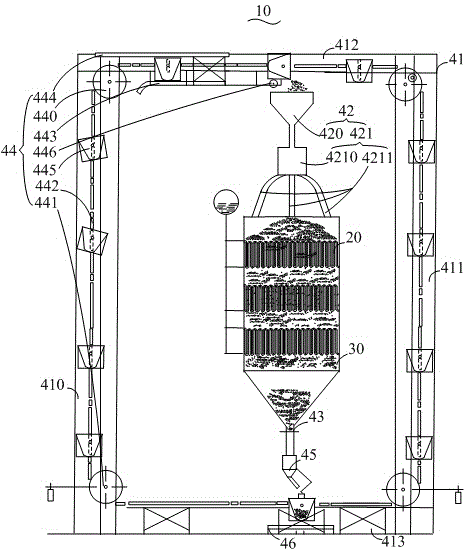

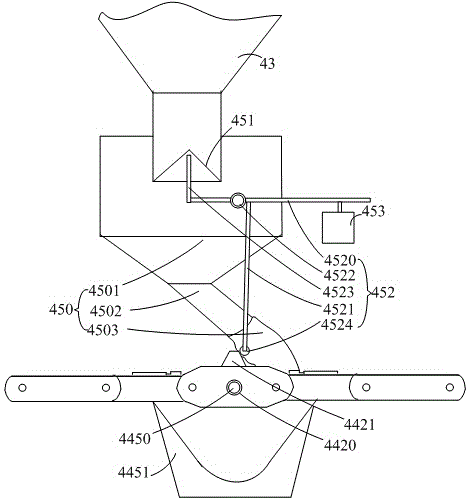

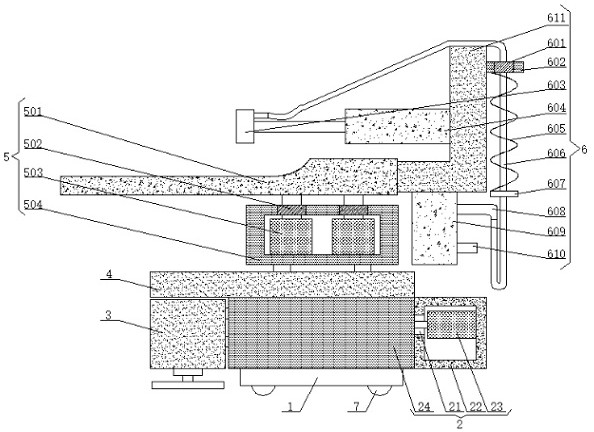

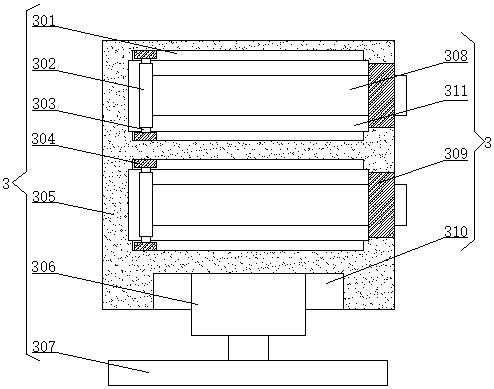

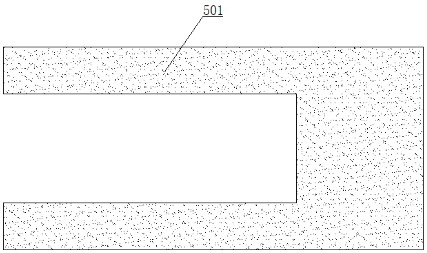

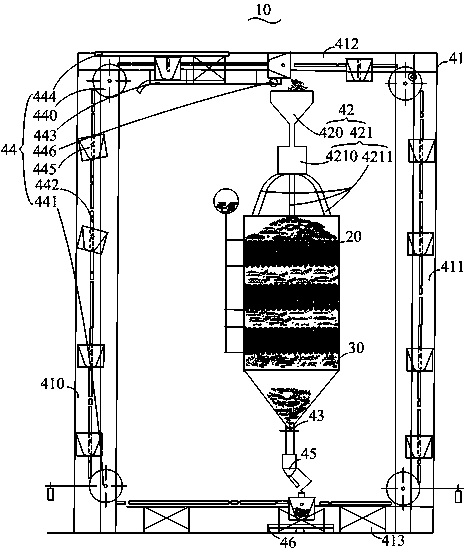

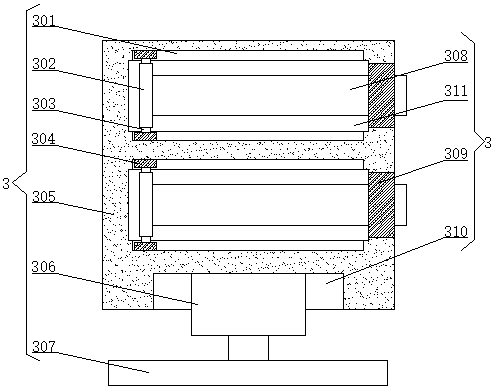

Steel ball dust removal type submerged arc furnace waste heat boiler for easy recovery of steel balls

ActiveCN104132543BGuaranteed normal dumpingRealize centralized collectionIncreasing energy efficiencySolid removalBall typeEngineering

A steel-ball-dedusting type submerged-arc-furnace waste heat boiler convenient for steel balls recycling comprises a cyclic steel column mechanical soot cleaning device. A fine adjustment plate of a cyclic steel ball mechanical transport device of the cyclic steel ball mechanical soot cleaning device and a rough adjustment rod are parallelly arranged, the fine adjustment plate is under the rough adjustment rod, the distance between the fine adjustment plate and the rough adjustment rod corresponds to the overall height of a steel ball transport bucket, the steel ball transport bucket loaded with the steel balls firstly contacts with the fine adjustment plate and the rough adjustment rod for horizontal adjustment prior to contacting with a mechanical unloading retainer wheel to be supplied with turnover driving force through the mechanical unloading retainer wheel, a steel ball recycling groove of the cyclic steel column mechanical soot cleaning device is fixed on a lower horizontal bearing support of a support frame of the cyclic steel column mechanical soot cleaning device, and the steel ball recycling groove is located under a guiding channel of the cyclic steel column mechanical soot cleaning device and under the steel ball transport bucket receiving the steel balls discharged from the guiding channel.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

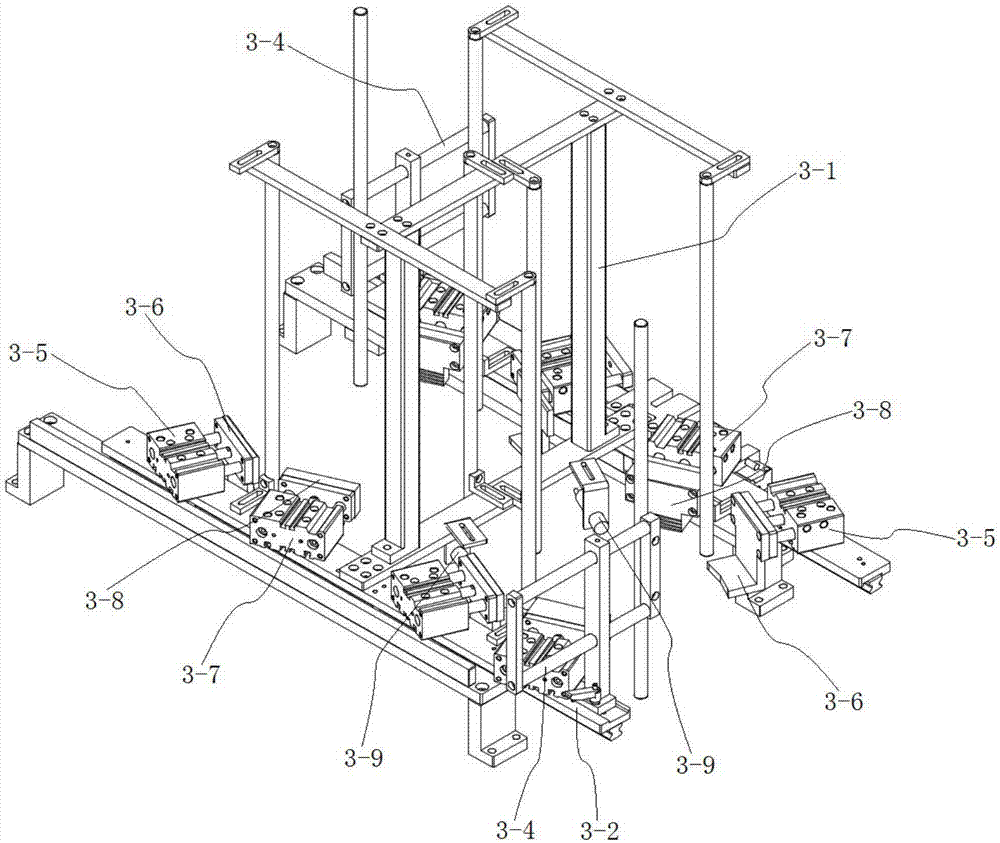

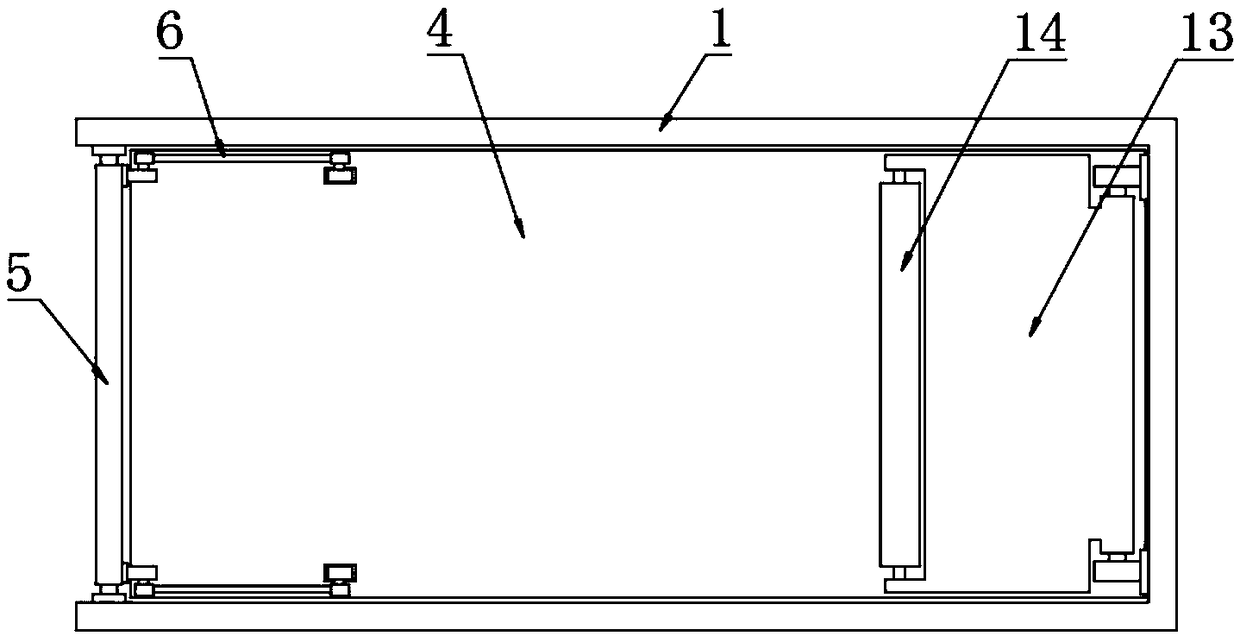

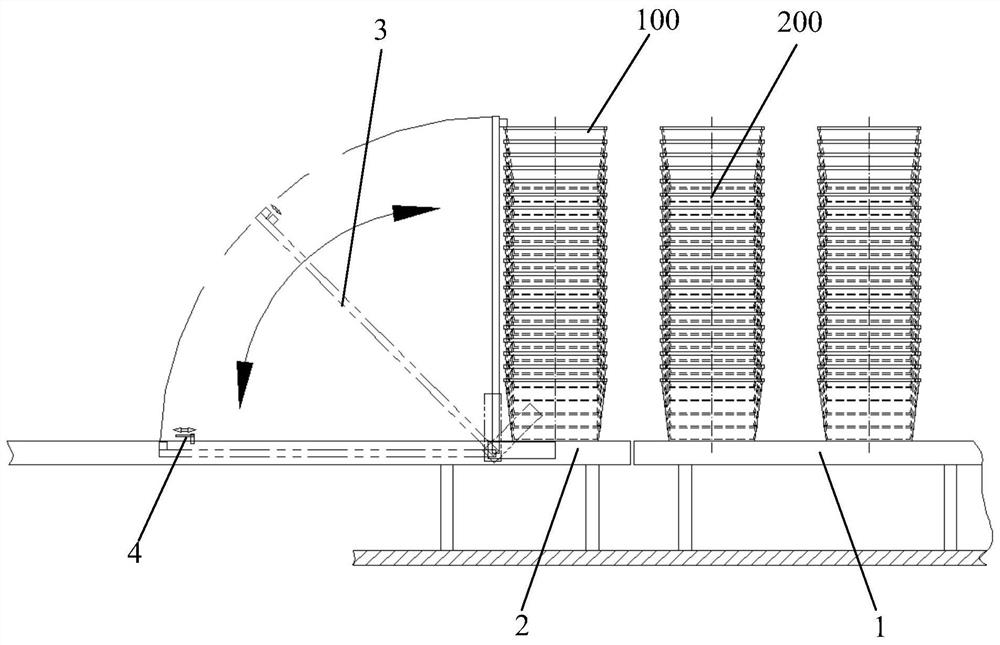

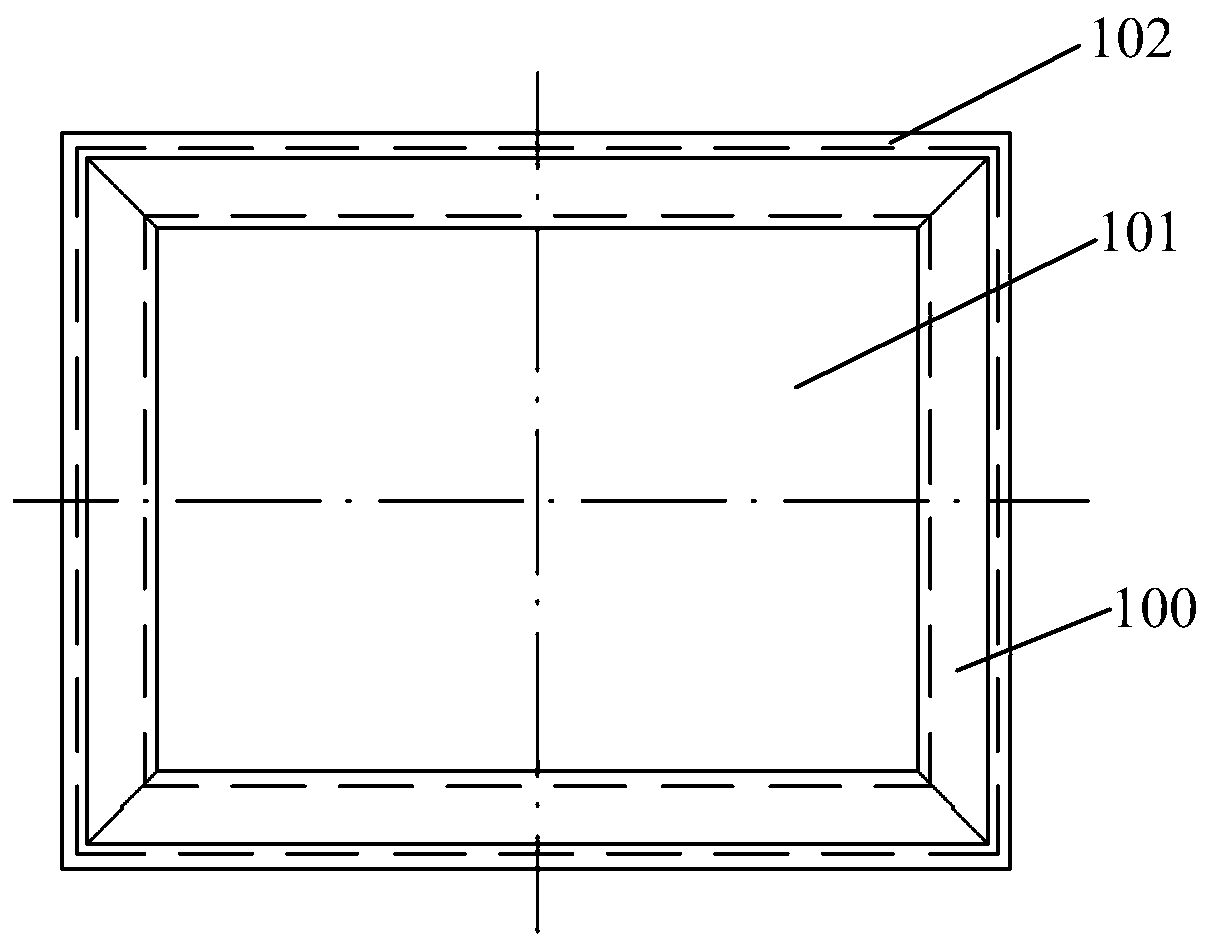

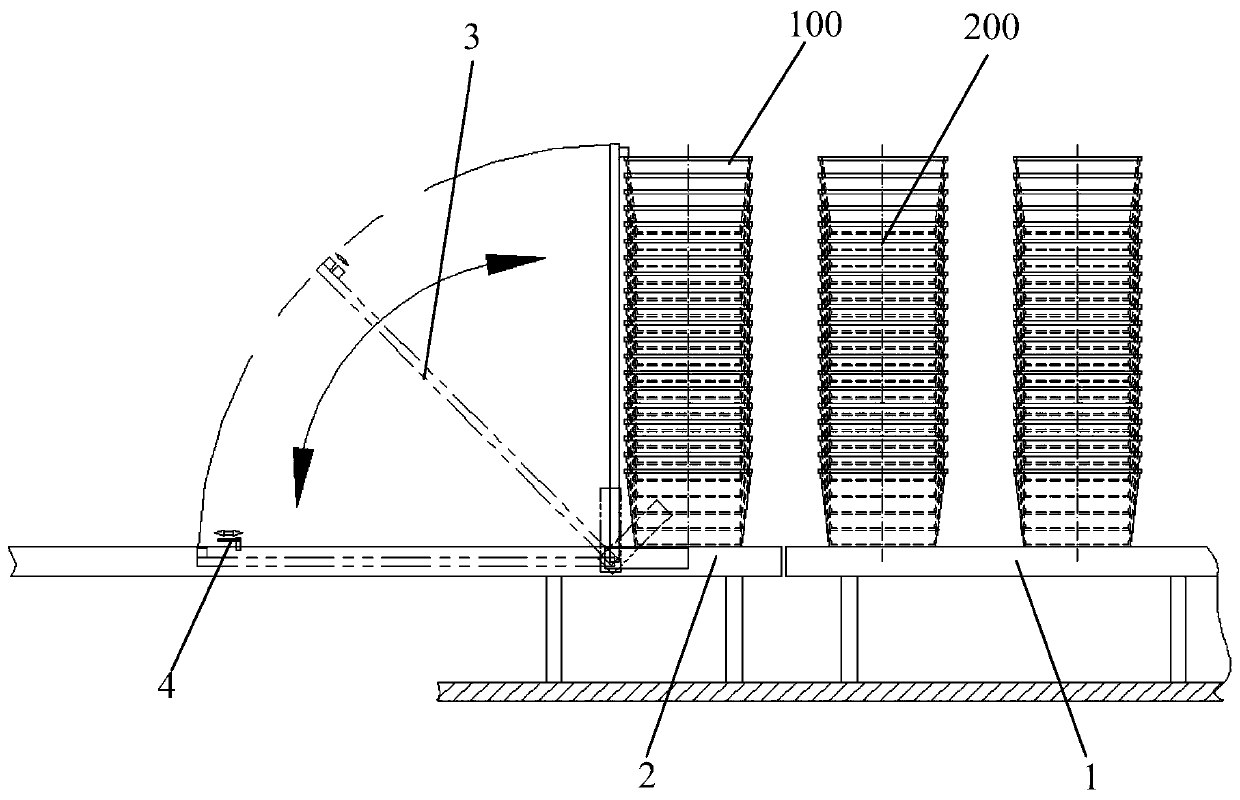

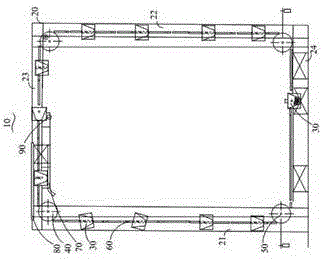

A Turnover Box Automatic Splitting System

InactiveCN110077863BSave human effortHigh split efficiencyDe-stacking articlesControl systemControl engineering

The invention discloses an automatic splitting system of circulation boxes. The automatic splitting system of circulation boxes comprises a stepping conveyor, a roller conveyor, a toppling gripper mechanism, splitting mechanisms and an electrical control system, wherein a starting end of the roller conveyor is connected with a tail end of the stepping conveyor, and the roller conveyor is used fortransferring circulation box groups on the stepping conveyor to the roller conveyor; the toppling gripper mechanism is arranged on the roller conveyor in a swinging mode and is close to the starting end of the roller conveyor, and the toppling gripper mechanism is used for gripping an upper end and a lower end of the circulation box groups which are arranged vertically and then toppling the circulation box groups, so that the circulation box groups are placed in a horizontal state; two splitting mechanisms are the same in structure and are symmetrically arranged on two sides of the roller conveyor, and the two splitting mechanisms are used for carrying out layer-by-layer splitting of the horizontally-placed circulation box groups; and the electrical control system is electrically connectedwith all the mechanisms. According to the automatic splitting system of circulation boxes, the operation efficiency is improved, and the resources are saved; and the problem that the circulation boxes are damaged due to manual splitting of the circulation boxes is avoided, and the service life of the circulation boxes is prolonged;

Owner:YUNNAN UNIVERSITY OF FINANCE AND ECONOMICS

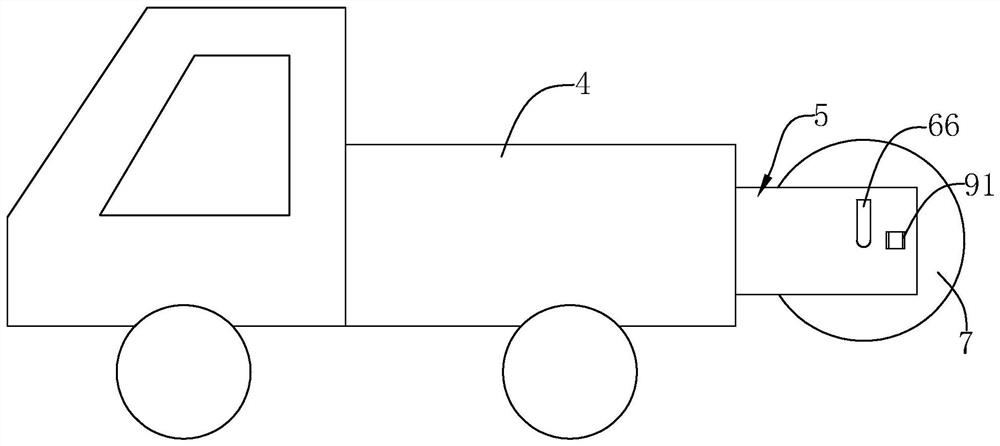

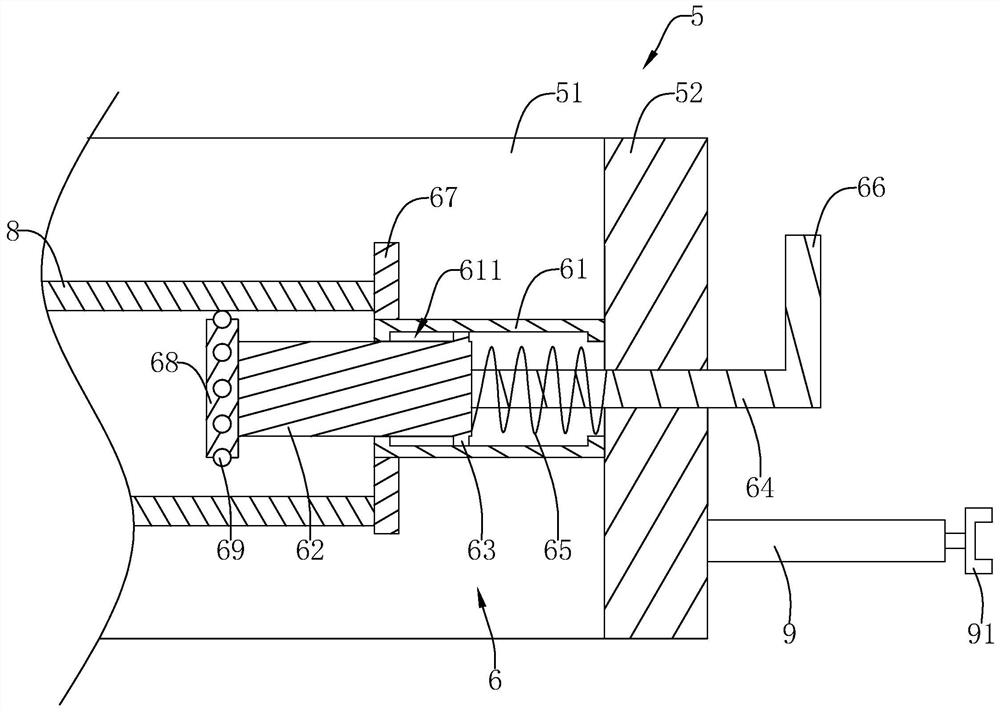

Automatic collection and transportation garbage truck

The invention discloses an automatic collection and transportation garbage truck, relates to the technical field of garbage trucks, and provides the following scheme for solving the problems that an existing garbage truck cannot conveniently clamp and dump garbage cans and cannot conveniently control thorough dumping and residues are likely to be left during dumping. The automatic collection and transportation garbage truck comprises a carriage, wherein a material receiving box is fixedly connected to the bottom of the left side of the carriage; a sleeve is fixedly connected to the top of thematerial receiving box; a protective cover is fixedly connected to the top of the sleeve; a feeding worm is movably arranged in the sleeve in a sleeving mode; a rotating shaft is fixedly connected tothe top end of the feeding worm; a driving mechanism is fixedly connected to the top end of the rotating shaft; a lifting plate is fixedly connected to the right side of the driving mechanism; a pushrod motor is fixedly connected to the right side of the bottom of the lifting plate; and the bottom end of the push rod motor is fixedly connected with the carriage. According to the automatic collection and transportation garbage truck, the garbage cans do not need to be clamped to be overturned and dumped, only garbage needs to be poured into the material receiving box, it is rapidly and conveniently guaranteed that garbage is dumped thoroughly, one machine has multiple purposes, and the practicability of the device is improved.

Owner:CHANGDE DINGCHENG LINYU AUTOMOTIVE PARTS

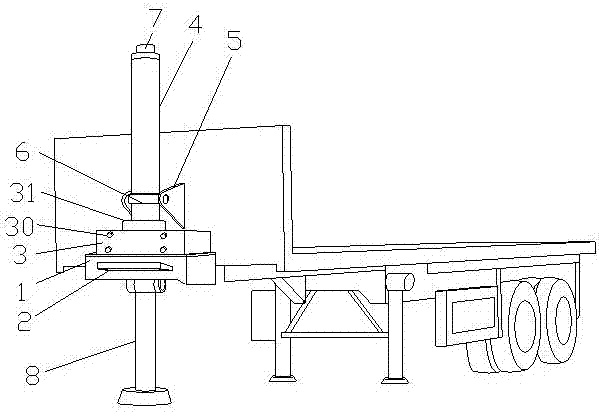

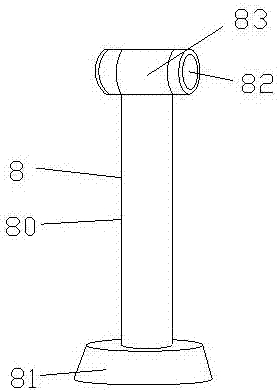

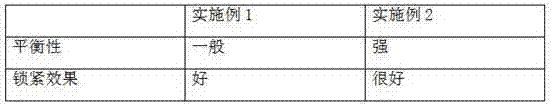

Semi-trailer locking device provided with self-unloading booster

InactiveCN107298075AAvoid leaning forwardEnsure safetyVehicle fittings for liftingInterference fitEngineering

The invention discloses a locking device for a semi-trailer with a self-unloading booster. The tightening bolt is fixedly welded to the front end surface of the locking seat beam, the cylinder seat is fixedly welded to the upper surface of the locking seat beam, the cylinder block is movably connected to the upper surface of the cylinder seat, and the front outer surface of the cylinder block is nested with a sealing ring. The sealing ring and the cylinder block are connected by an interference fit. The left and right end surfaces of the sealing ring are connected with fixing plates by screws, and the cylinder head is movably connected to the upper surface of the cylinder block. The present invention can be carried out on semi-trailers. During the self-unloading and locking process, it plays a certain bottom support role while automatically lifting, avoiding the forward tilt of the vehicle body due to imbalance, ensuring the safety of the vehicle during self-unloading and locking, and effectively improving the safety of the equipment. performance and stability.

Owner:卢元碧

Automatic splitting system of circulation boxes

InactiveCN110077863ASave human effortHigh split efficiencyDe-stacking articlesElectricityElectrical control

The invention discloses an automatic splitting system of circulation boxes. The automatic splitting system of circulation boxes comprises a stepping conveyor, a roller conveyor, a toppling gripper mechanism, splitting mechanisms and an electrical control system, wherein a starting end of the roller conveyor is connected with a tail end of the stepping conveyor, and the roller conveyor is used fortransferring circulation box groups on the stepping conveyor to the roller conveyor; the toppling gripper mechanism is arranged on the roller conveyor in a swinging mode and is close to the starting end of the roller conveyor, and the toppling gripper mechanism is used for gripping an upper end and a lower end of the circulation box groups which are arranged vertically and then toppling the circulation box groups, so that the circulation box groups are placed in a horizontal state; two splitting mechanisms are the same in structure and are symmetrically arranged on two sides of the roller conveyor, and the two splitting mechanisms are used for carrying out layer-by-layer splitting of the horizontally-placed circulation box groups; and the electrical control system is electrically connectedwith all the mechanisms. According to the automatic splitting system of circulation boxes, the operation efficiency is improved, and the resources are saved; and the problem that the circulation boxes are damaged due to manual splitting of the circulation boxes is avoided, and the service life of the circulation boxes is prolonged;

Owner:YUNNAN UNIVERSITY OF FINANCE AND ECONOMICS

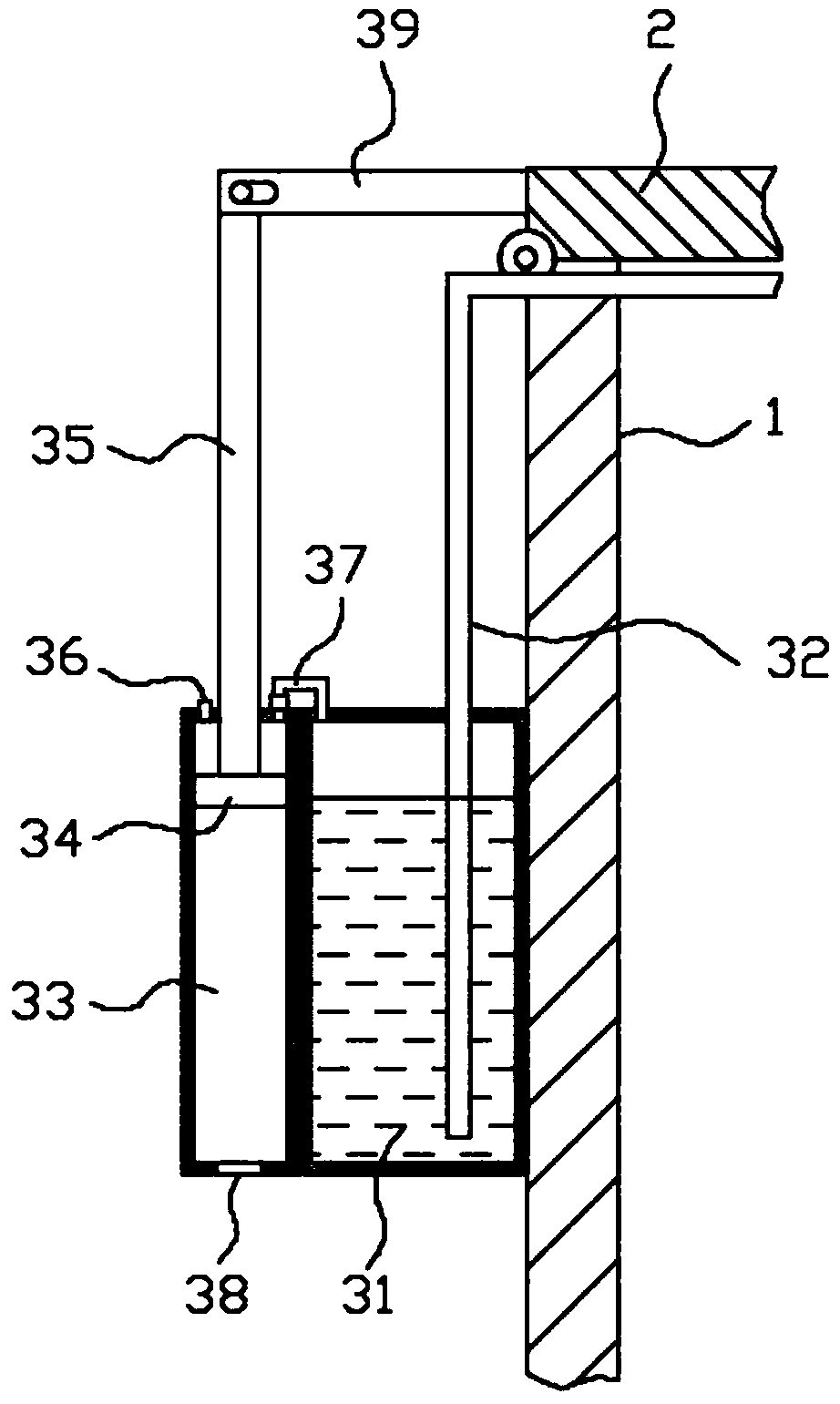

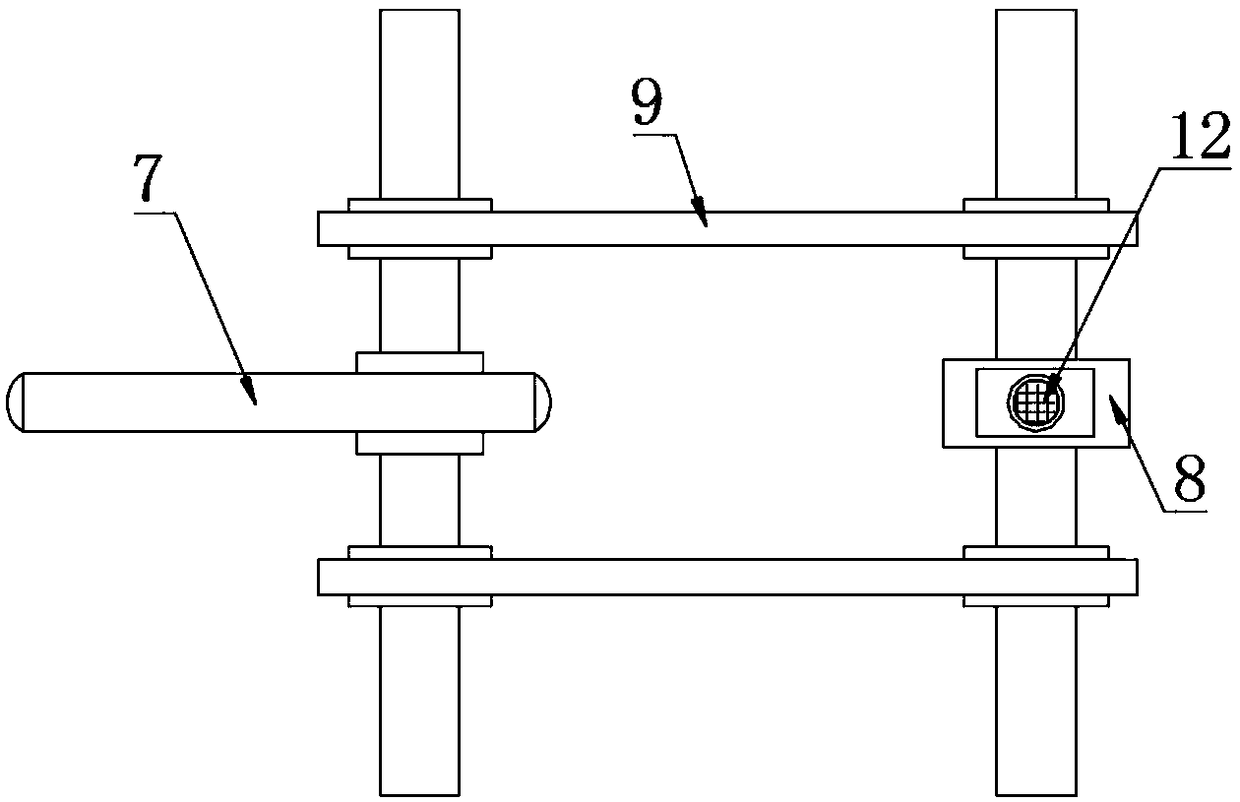

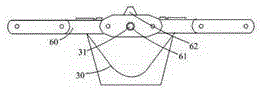

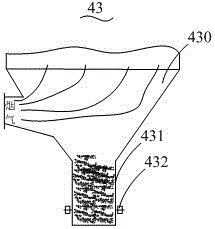

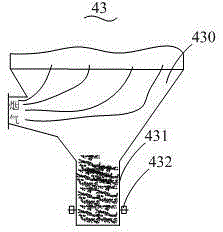

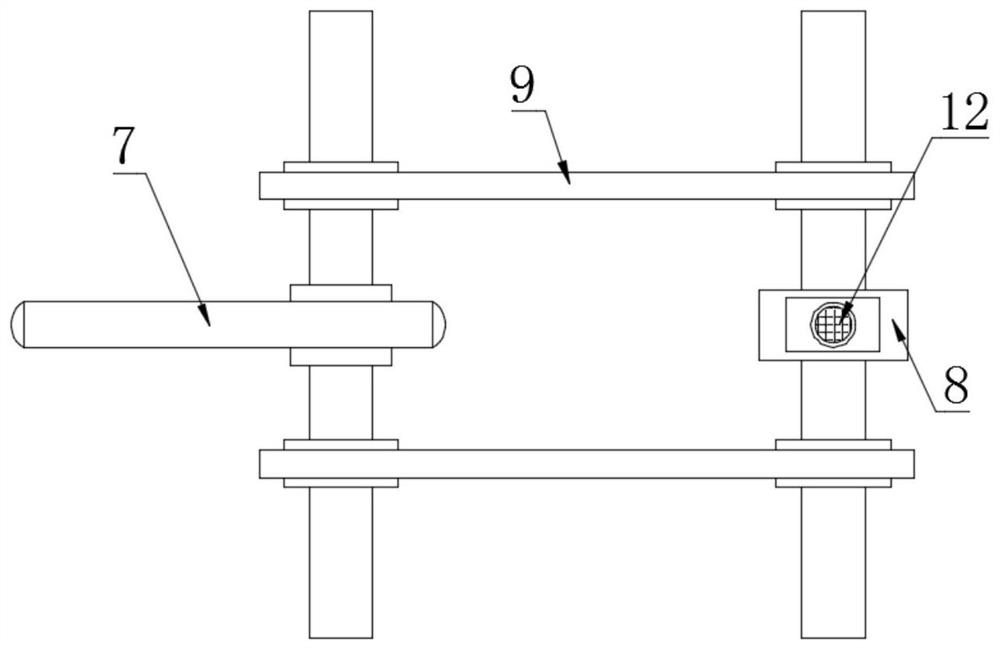

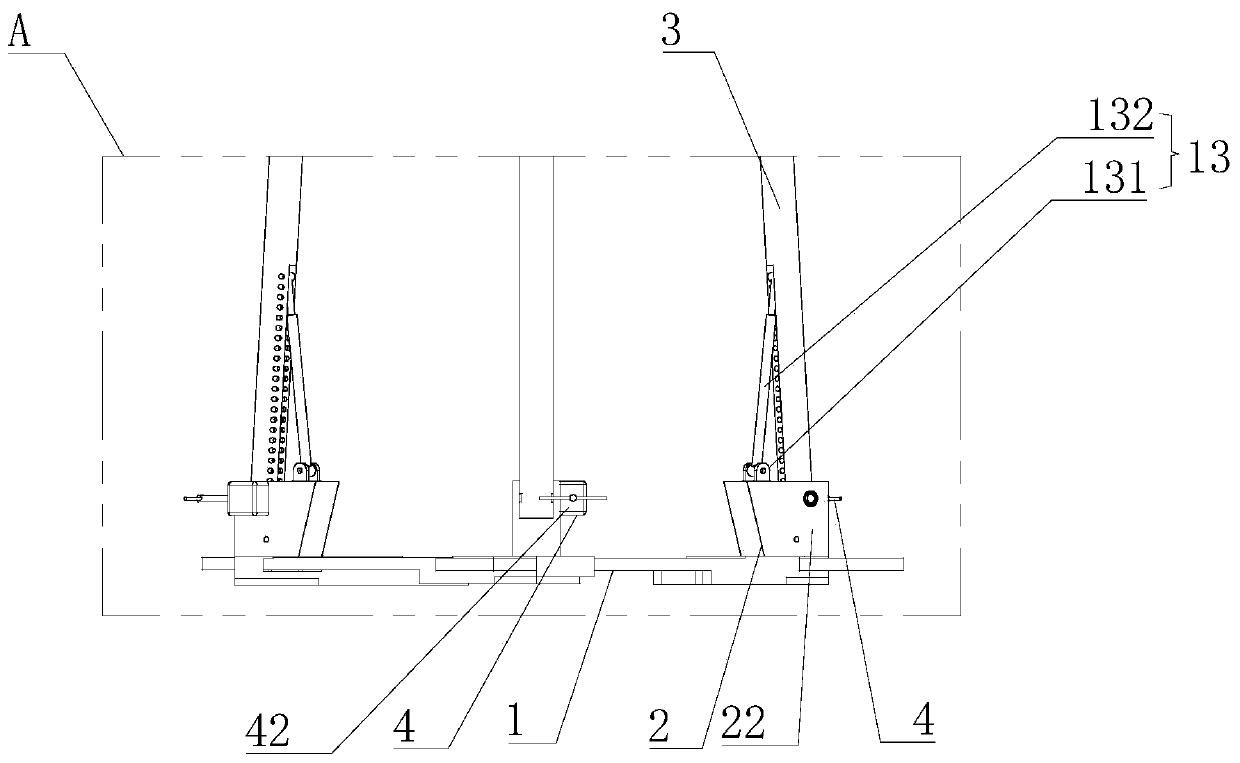

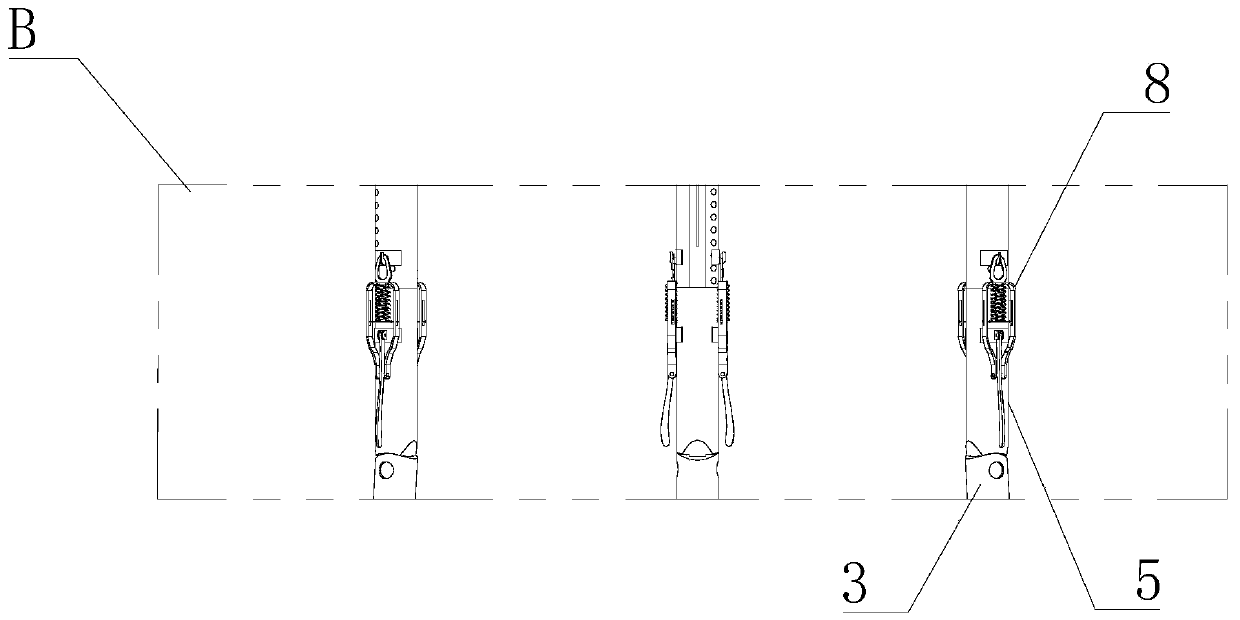

Cyclic type mechanical conveying device for steel balls

The invention relates to a cyclic type mechanical conveying device for steel balls. The cyclic type mechanical conveying device comprises a supporting frame, a steel ball conveying hopper, a driving wheel, a driven wheel, two rows of chains, a fine adjustment correcting plate, a rough adjustment correcting rod and a mechanical discharge blocking wheel, wherein the driving wheel, the driven wheel, the two rows of chains, the fine adjustment correcting plate, the rough adjustment correcting rod and the mechanical discharge blocking wheel are fixed to the supporting frame. The fine adjustment correcting plate, the coarse adjustment correcting rod and the mechanical discharge blocking wheel are fixed to an upper transverse bearing frame. The fine adjustment correcting plate and the coarse adjustment correcting rod are arranged in parallel. The fine adjustment correcting plate is located below the coarse adjustment correcting rod. The distance between the fine adjustment correcting plate and the coarse adjustment correcting rod corresponds to the overall height of the steel ball conveying hopper. The steel ball conveying hopper containing steel balls makes contact with the fine adjustment correcting plate and the coarse adjustment correcting rod at first for horizontal correction and then makes contact with the mechanical discharge blocking wheel so as to provide overturning driving force through the mechanical discharge blocking wheel.

Owner:李素梅

A kind of paving method for landfill operation of garbage landfill

ActiveCN112453006BEnsure safetyImprove efficiencySolid waste disposalLandfill technologiesDeodorantEngineering

Owner:北京银都建设工程集团有限公司

Reinforcement structure and method of double cement type pole tower in goaf of coal mine

The invention discloses a reinforcing structure and method of a double-cement tower in a coal gob area and aims at reinforcing a double-cement tower, keeping a favorable reinforcing deviation rectifying effect, meeting the requirement for safety operation of a line, reaching the operation standard of the line, realizing in-advance precaution and prevention of hidden dangers and keeping safety production. The adopted technical scheme is as follows: a strip-shaped foundation is poured on a double-cement tower foundation and is used as a foundation to be reinforced, a planar steel plate is embedded in the strip-shaped foundation and is fixedly provided with a plurality of groups of channel steel clinging to a pole body of the double-cement tower, the channel steel is provided with upright column channel steel fixedly connected with the pole body of the double-cement tower, the pole body of the double-cement tower is reinforced by using the channel steel and the upright column channel steel, meanwhile, a cross arm of the double-cement tower is supported by a U-shaped clamping slot in the top of the upright column channel steel, an insulator string which is hung by using a vertical steel cored stranded wire is hung at the lower end of every phase conductor of the double-cement tower, and a length-adjustable 45-DEG bracing wire is connected to the double-cement tower.

Owner:STATE GRID CORP OF CHINA +1

Steel-ball-dedusting type submerged-arc-furnace waste heat boiler capable of keeping balance of steel ball transport bucket

ActiveCN104132549AGuaranteed normal dumpingIncreasing energy efficiencySolid removalGear wheelDust control

A steel-ball-dedusting type submerged-arc-furnace waste heat boiler capable of keeping balance of a steel ball transport bucket comprises a cyclic steel column mechanical soot cleaning device. A fine adjustment plate of a cyclic steel ball mechanical transport device of the cyclic steel column mechanical soot cleaning device and a rough adjustment rod are parallelly arranged, the fine adjustment plate is located under the rough adjustment rod, the distance between the fine adjustment plate and the rough adjustment rod corresponds to the overall height of the steel ball transport bucket, and the steel ball transport bucket loaded with steel balls firstly contacts with the fine adjustment plate and the rough adjustment rod for horizontal adjustment prior to contacting with a mechanical unloading retainer wheel so as to be supplied with turnover driving force through the mechanical unloading retainer wheel, so that the steel ball transport bucket is allowed to reach a horizontal state through the fine adjustment plate and the rough adjustment rod after reaching an upper horizontal bearing frame, and therefore, the steel ball transport bucket is allowed to completely pour out the steel balls into a steel ball seeding device after contacting with the mechanical unloading gear wheel of the cyclic steel ball mechanical transport device.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Steel ball dust removal type submerged arc furnace waste heat boiler to keep the steel ball transport bucket balanced

ActiveCN104132549BGuaranteed normal dumpingIncreasing energy efficiencySolid removalDust controlEngineering

A steel ball dedusting submerged arc furnace waste heat boiler that maintains the balance of the steel ball transport bucket, including a circulating steel column mechanical dust removal device, a fine adjustment correction plate for the circulating steel ball mechanical transport device, and a coarse The bar correction rods are set in parallel, the fine adjustment correction plate is located under the thick bar correction rod, the distance between the fine adjustment correction plate and the thick bar correction rod corresponds to the overall height of the steel ball transport bucket, the steel ball transport bucket with steel balls First contact with the fine adjustment correction plate and the thick correction rod for horizontal correction, and then contact with the mechanical discharge stop wheel to provide the overturning driving force through the mechanical discharge stop wheel, so that when the steel ball transport bucket reaches the upper transverse bearing frame Finally, the steel ball transport bucket is leveled by fine-tuning the correction plate and the thick correction rod first, so as to ensure that the water in the steel ball transport bucket is completely transported after contacting the mechanical discharge retaining wheel of the circulating steel ball mechanical transport device. The steel balls are poured into the steel ball spreading device.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Steel ball dust removal submerged arc furnace waste heat boiler

ActiveCN104132548BGuaranteed normal dumpingIncreasing energy efficiencySolid removalSteel ballEngineering

A steel ball dedusting-type submerged arc furnace waste heat boiler comprises a circulating-type steel ball mechanical dedusting device. A fine-adjustment correcting plate and a rough-adjustment correcting rod of a circulating-type steel ball mechanical transporting device of the circulating-type steel ball mechanical dedusting device are arranged parallelly, the fine-adjustment correcting plate is positioned below the rough-adjustment correcting rod, and a distance between the fine-adjustment correcting plate and the rough-adjustment correcting rod corresponds to overall height of a steel ball transporting bucket. The steel ball transporting bucket in which steel balls are contained contacts with the fine-adjustment correcting plate and the rough-adjustment correcting rod to perform horizontal correcting, and then contacts with a mechanical discharging retaining wheel to provide turnover driving force through the mechanical discharging retaining wheel, in this way, after reaching an upper transverse bearing frame, the steel ball transporting bucket is enabled to be in a horizontal state through the fine-adjustment correcting plate and the rough-adjustment correcting rod, so that after the steel ball transporting bucket contacts with the mechanical discharging retaining wheel of the circulating-type steel ball mechanical transporting device, transported steel balls can be ensured to be poured into a steel ball scattering device.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

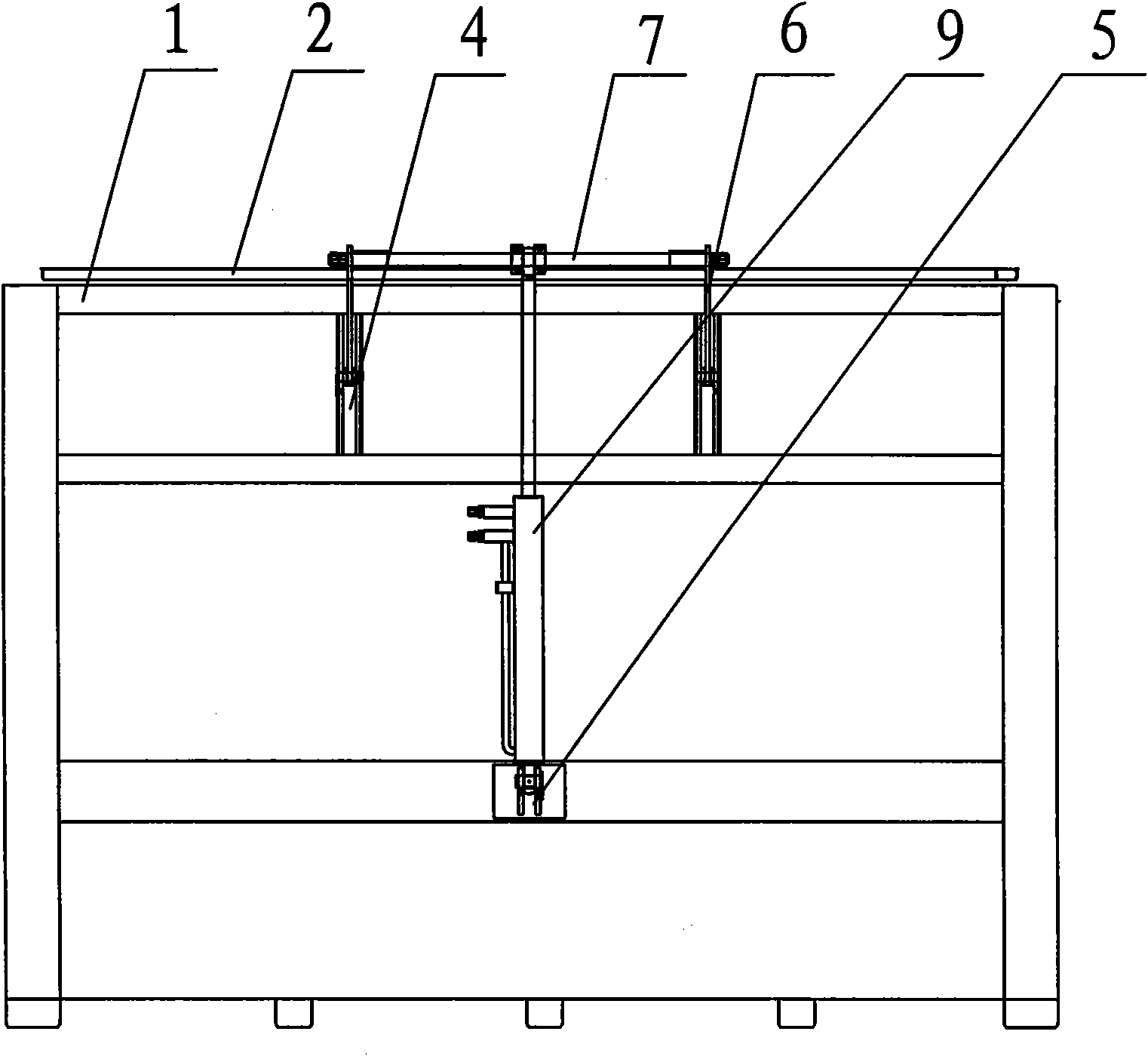

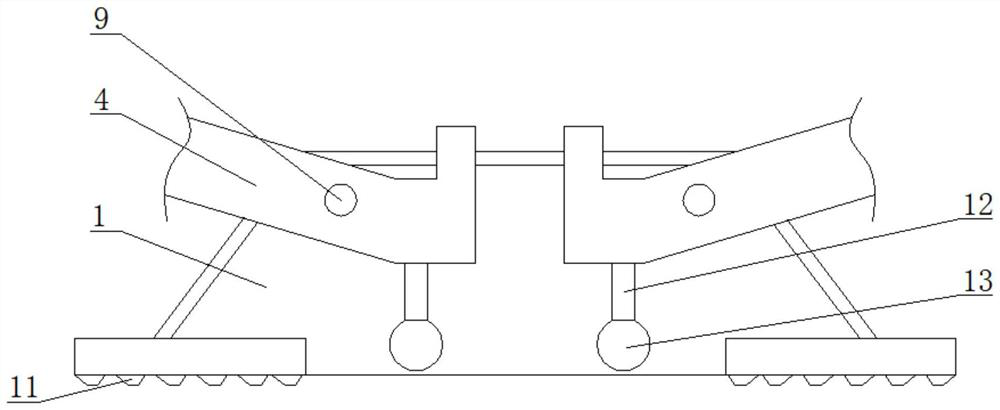

Maintenance and cleaning auxiliary mechanism for concrete mixer

ActiveCN108746118BEasy to liftEasy maintenance and repairHollow article cleaningLifting devicesClassical mechanicsElectro hydraulic

Owner:德州市洛泰商贸有限公司

Steel ball dust removal type submerged arc furnace waste heat boiler to prevent steel balls from popping out

A steel ball dedusting submerged arc furnace waste heat boiler that prevents steel balls from popping up, including a circulating steel column mechanical dust removal device, and a steel ball lock wind charging device of the circular steel column mechanical dust removal device includes a hopper shell, a conical cap, a shaker The arm, the counterweight, the hopper shell include a conical funnel and a guide channel, the discharge port of the conical funnel is connected with the guide channel, the rocker arm includes a transverse rod, a steel ball discharge trigger, a rolling bearing and a conical cap connecting rod, in the double When the trigger plate on the row chain is in contact with the rotating wheel and moves relatively, the steel ball discharge trigger pushes the horizontal rod to rotate relative to the pin shaft, and the horizontal rod drives the conical cap through the conical cap connecting rod to make the discharge port far away from the steel ball separation and collection device The movement of the steel ball is to make the steel ball fall into the conical funnel, and the inner surface of the steel ball transport bucket is provided with a rubber buffer layer to prevent the steel ball from popping out.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Garbage truck for municipal sanitation cleaning

The invention discloses a garbage truck for municipal environmental sanitation cleaning. The garbage truck is characterized in that the upper part of a garbage can is opened, the bottom of the garbagecan is fixedly connected to a truck frame, the front part of the two sides of the truck frame are rotationally connected to side wheels in a bearing mode respectively, a driving wheel is arranged above the rear part of the truck frame, and the driving wheel is fixedly connected to the middle of the driving shaft; the upper part of the driving wheel is fixedly connected to a control rod, a cam isarranged behind the bottom of the garbage can, the cam is fixed to the center of a cam shaft, the two sides of the cam are provided with chain wheels respectively, and the chain wheels are fixedly connected to the cam shaft; the two sides of the driving wheel are also provided with chain wheels, and the chain wheels on the driving shaft and the two chain wheels on the cam shaft are correspondinglyconnected to each other through chains; a bottom plate is arranged below the garbage can, the lower surface of the front part of the bottom plate is hinged to the bottom of the garbage can, the lowersurface of the rear part of the bottom plate abuts against the cam, and a tail cover is arranged at the front part of the garbage can; and the upper end of the tail cover is rotationally connected tothe upper part of the front part of the garbage can, the two sides of the upper part of the tail cover are rotationally connected to the upper ends of connecting rods respectively, and the lower endsof the connecting rods are connected to the two sides of the bottom plate in a rotating mode.

Owner:HENAN YIXIANG SPECIAL VEHICLE

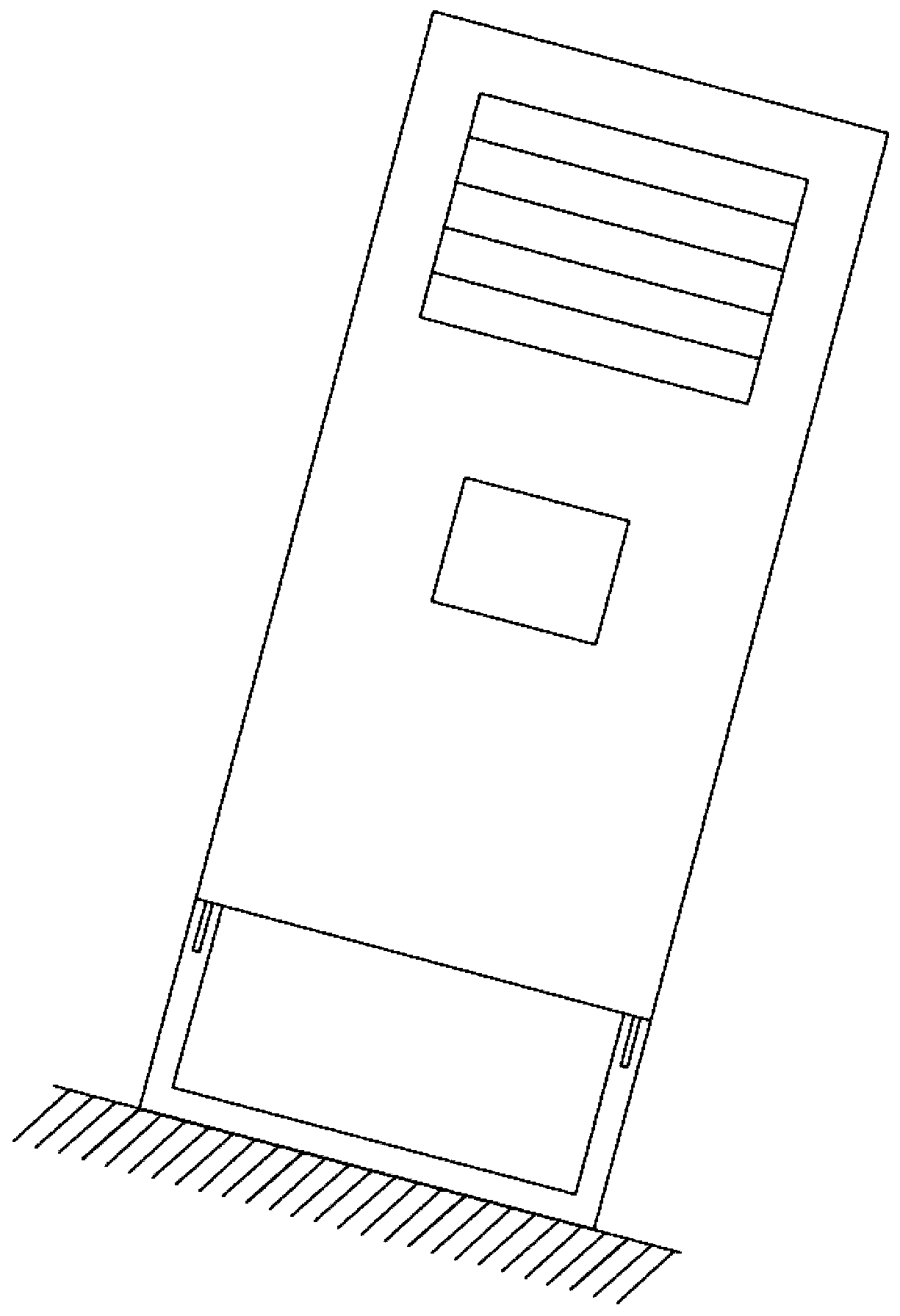

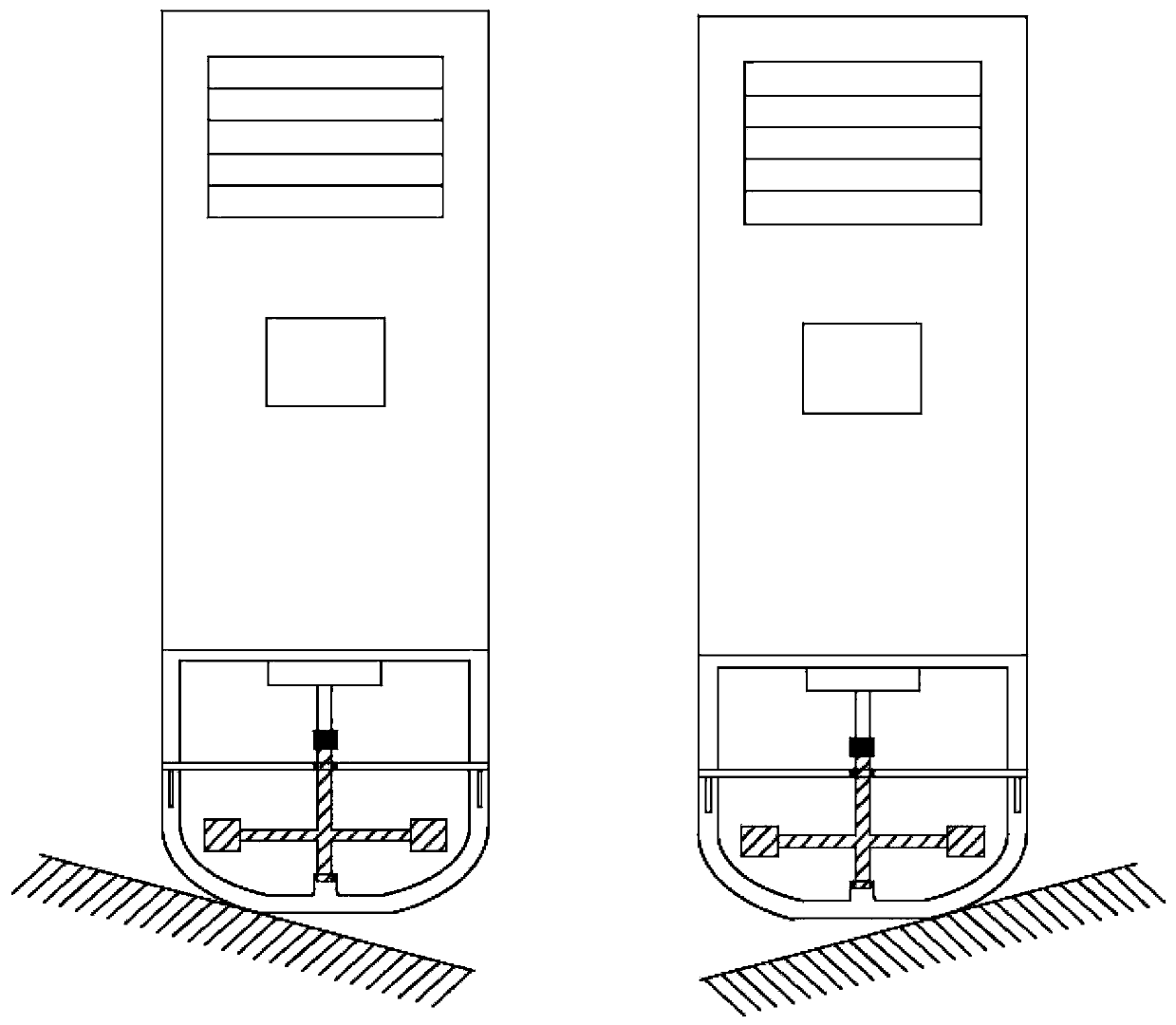

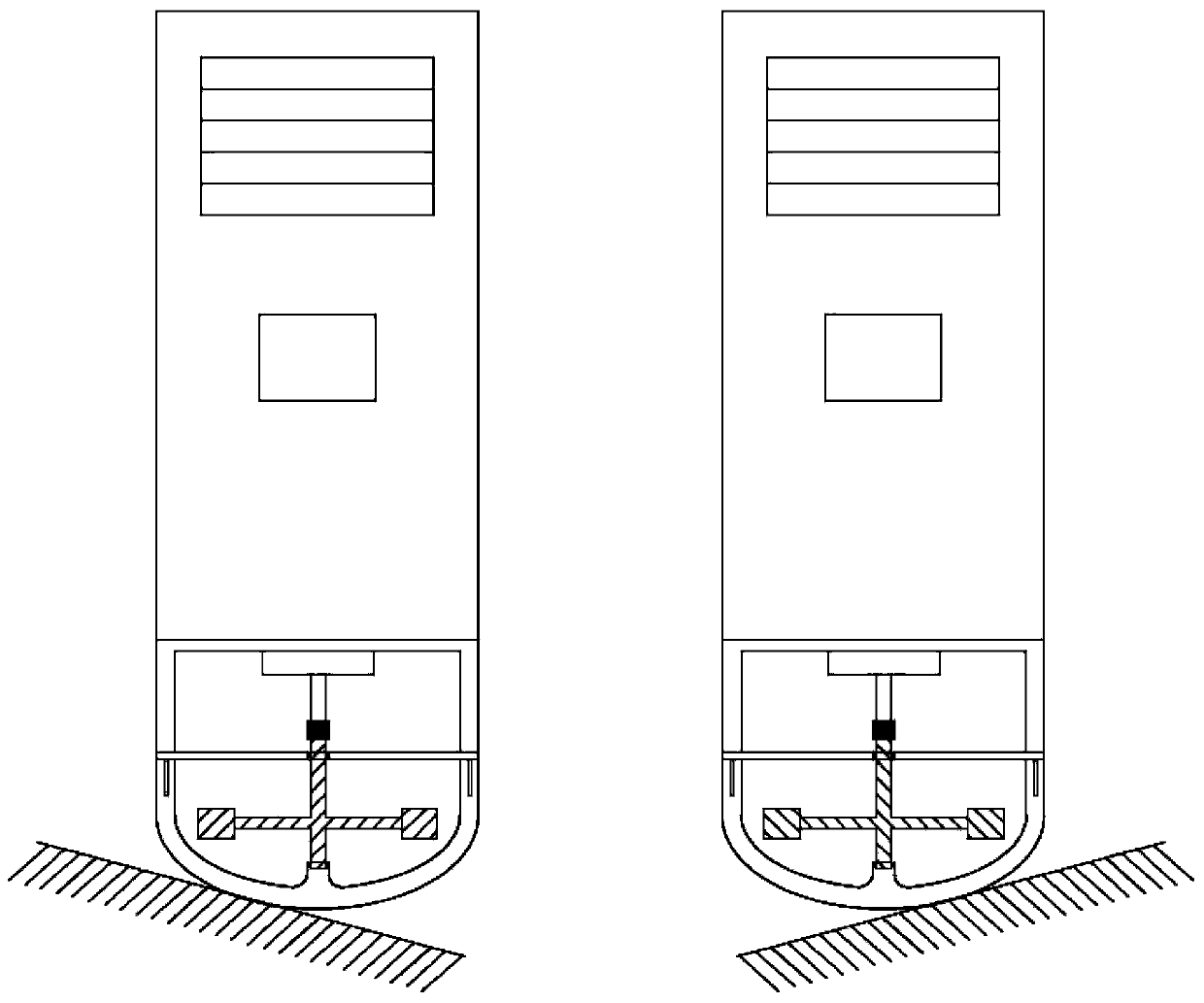

Anti-toppling air conditioner and control method

PendingCN110901873AGuaranteed normal dumpingGuaranteed not to dumpAuxillariesVessel ventillation/heating/coolingGyroscopeControl engineering

The invention provides an anti-toppling air conditioner and a control method, the anti-toppling air conditioner comprises a cabinet body and a base, and further comprises an anti-toppling assembly arranged in the base, and the anti-toppling assembly comprises a mechanical gyroscope and a motor for driving the mechanical gyroscope to operate. The gyroscope is arranged on the base, the air conditioner is stabilized on the central axis by means of the axis fixing performance of the gyroscope during high-speed operation, and the air conditioner can be prevented from toppling over even if a ship tilts.

Owner:NINGBO AUX ELECTRIC +1

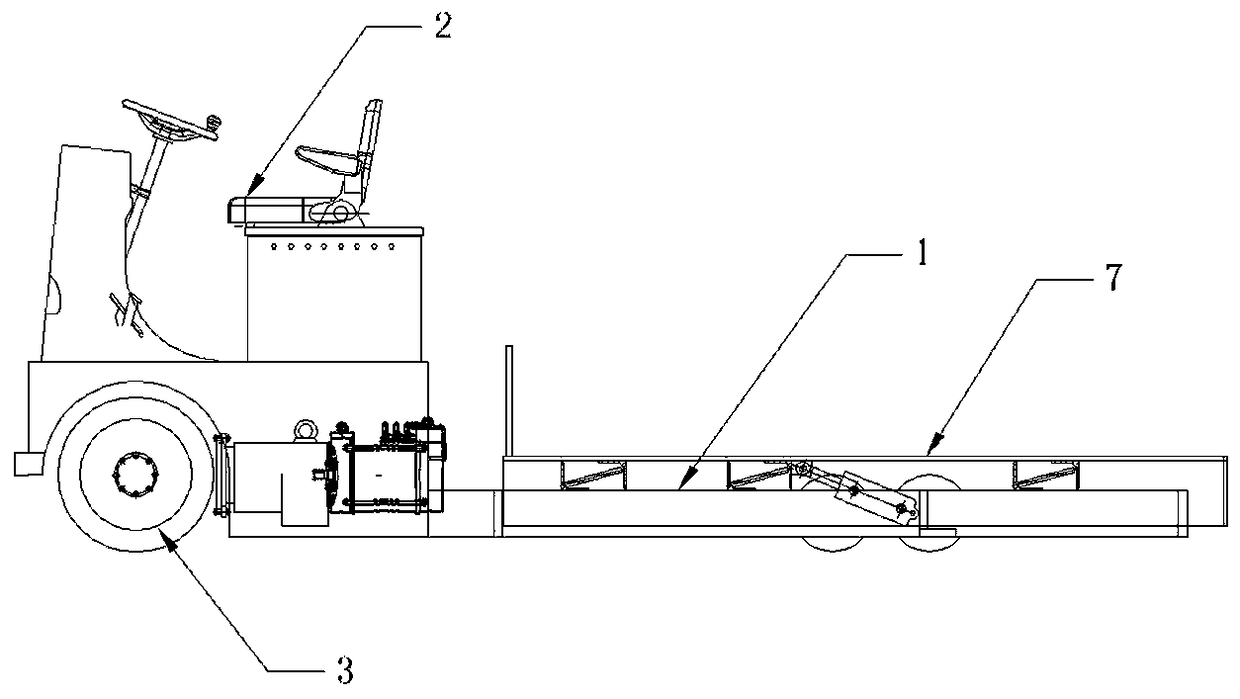

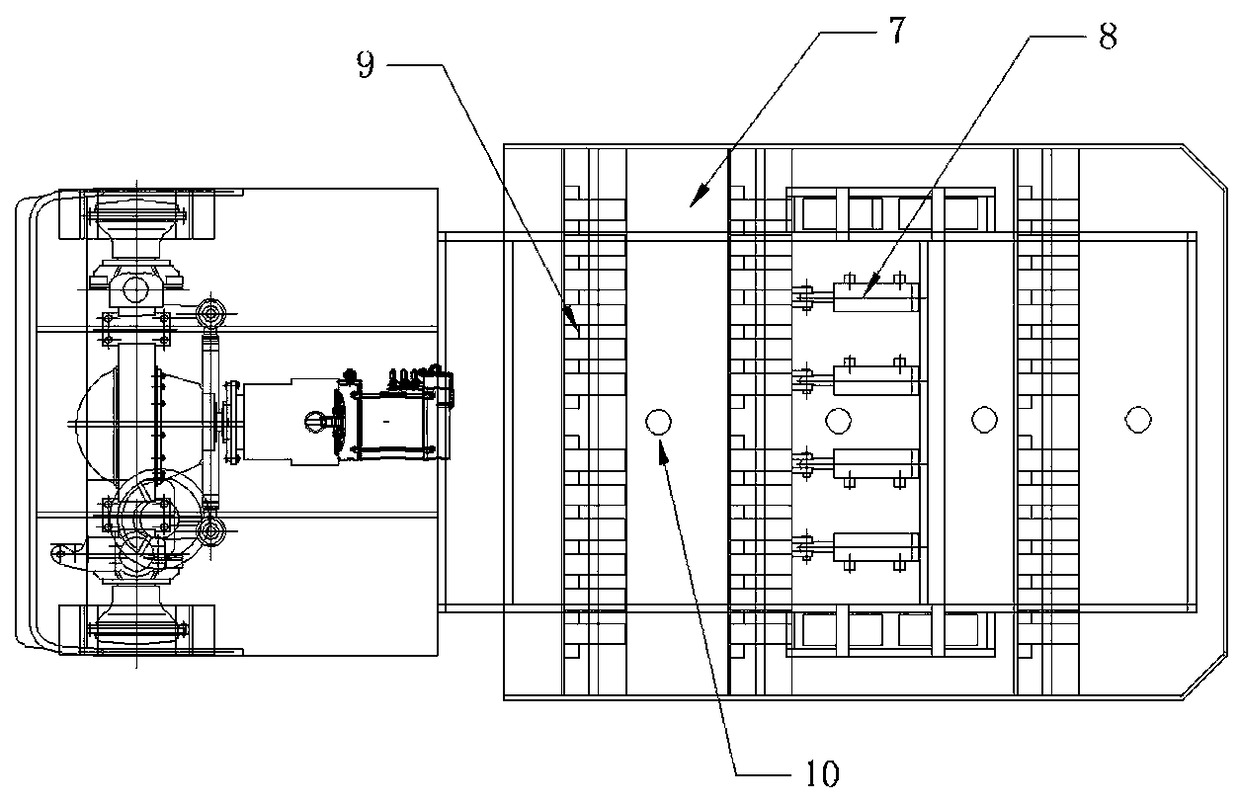

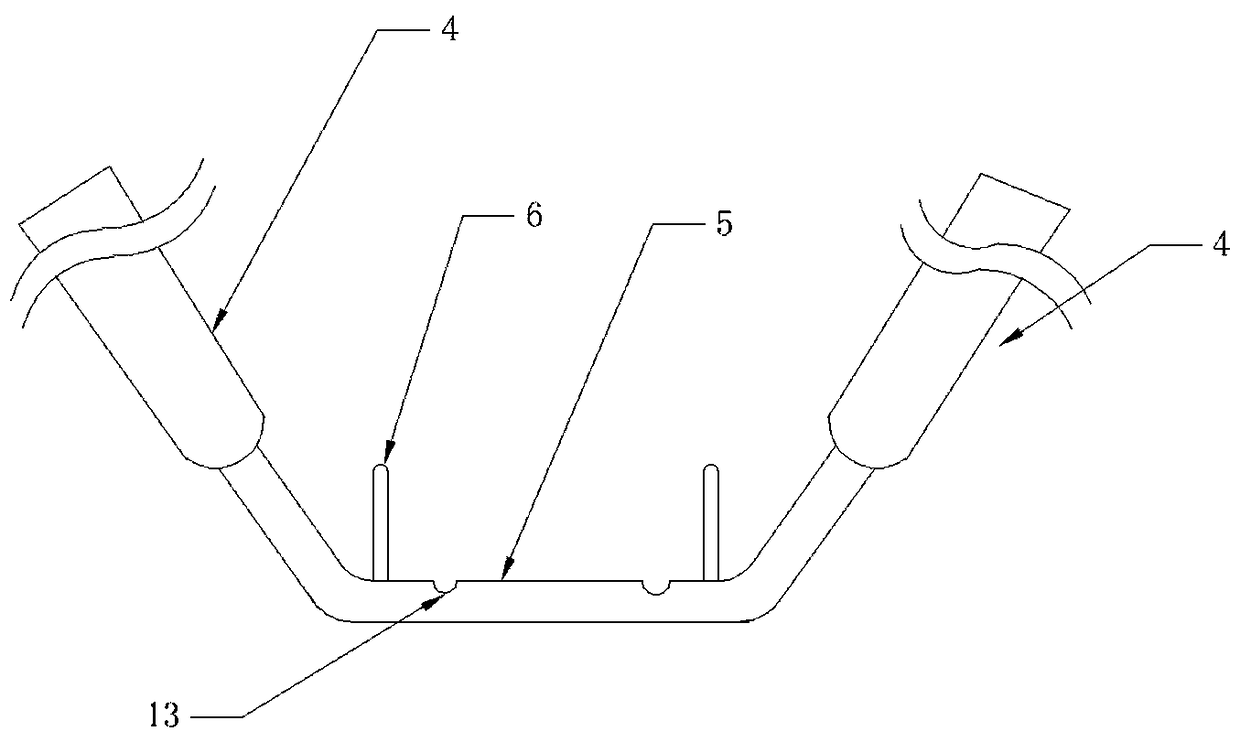

An all-electric ride-on pallet truck

A full-electric riding type pallet truck comprises a truck body. The front end of the truck body is provided with a cab and a control room. The truck body is provided with a drive device which comprises a power supply and a drive motor. Operation buttons used for controlling the drive motor are arranged in the control room. The drive motor is connected with the power supply and driving wheels under the truck body. The two sides of the truck body are separately provided with two pallet lifting mechanisms which comprise lifting oil cylinders, supporting plates and vertical fixing strips located on the supporting plates. The two sides of the supporting plates are all connected with the lifting oil cylinders. A pushing device used for pushing pallets is arranged on each supporting plate. The full-electric riding type pallet truck is simple in structure, brackets full of pallets can be automatically pushed onto the truck to be fixed when being put on the supporting plates, and labor is greatly saved; meanwhile, the two sides of the truck body are each provided with one pallet lifting mechanism, and the efficiency is further improved; and by adoption of the vertical fixing strips on the supporting plates, it can be ensured that the brackets do not deviate and fall in the using process.

Owner:HENGYANG LIMEI BATTERY VEHICLES MFG CO LTD

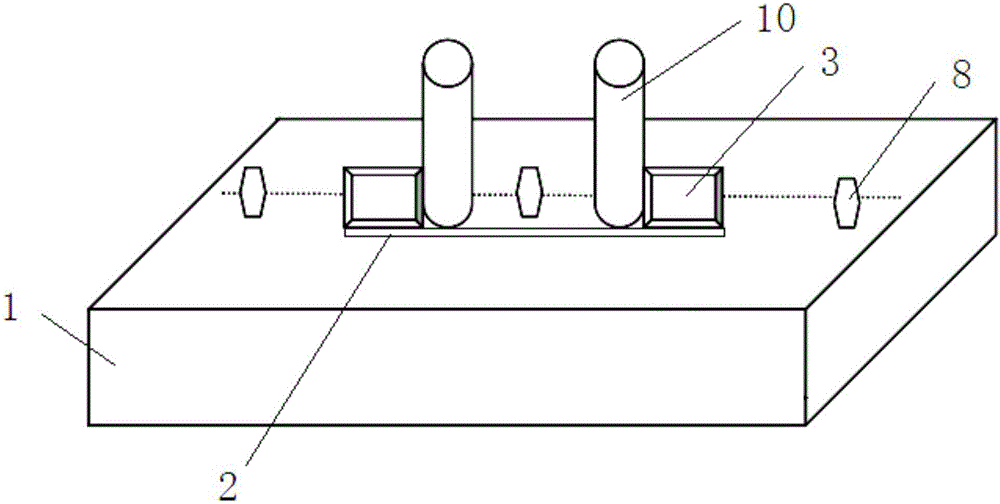

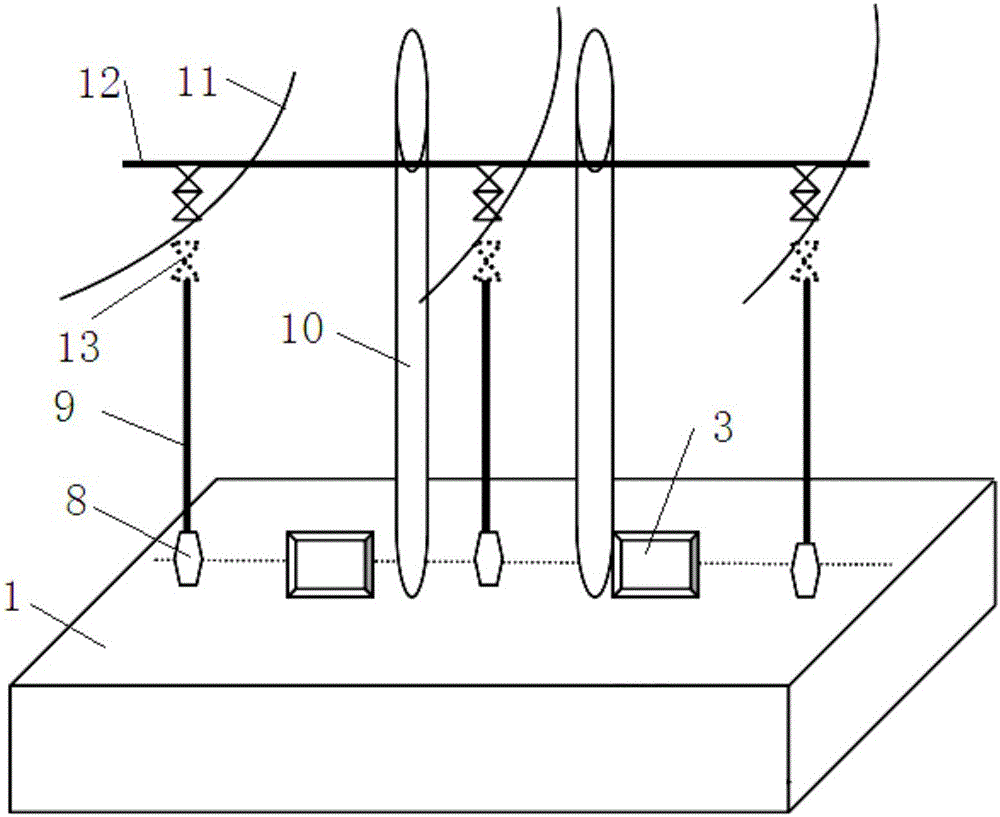

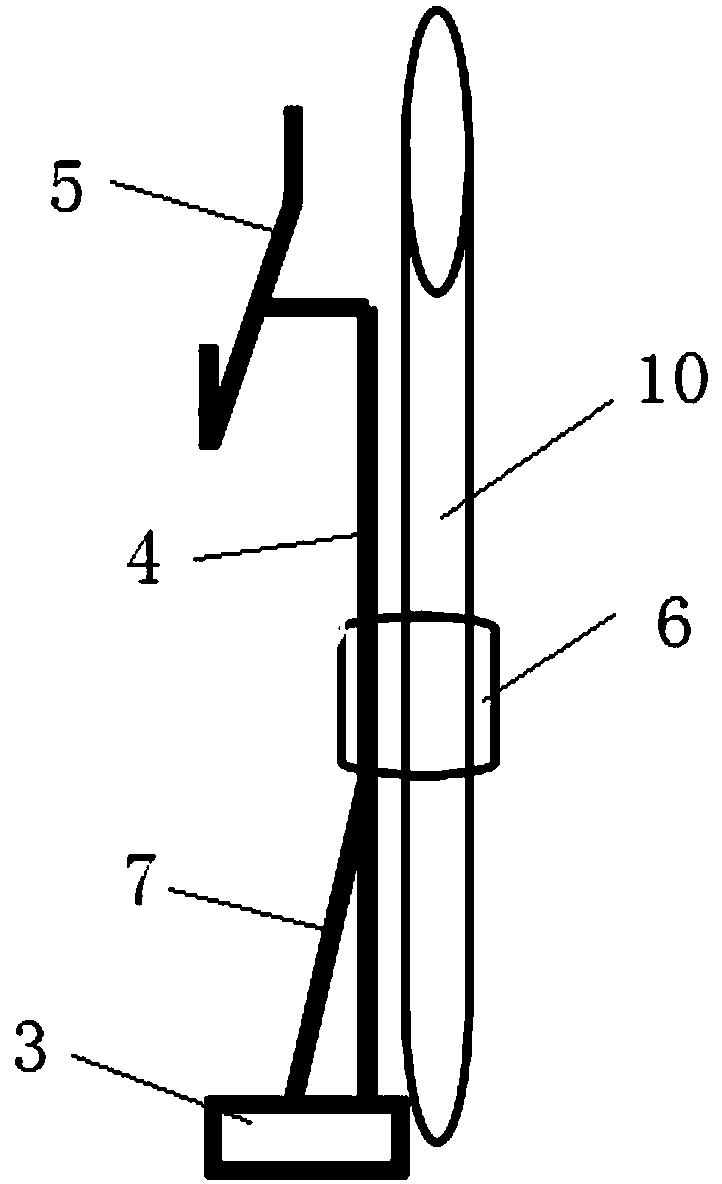

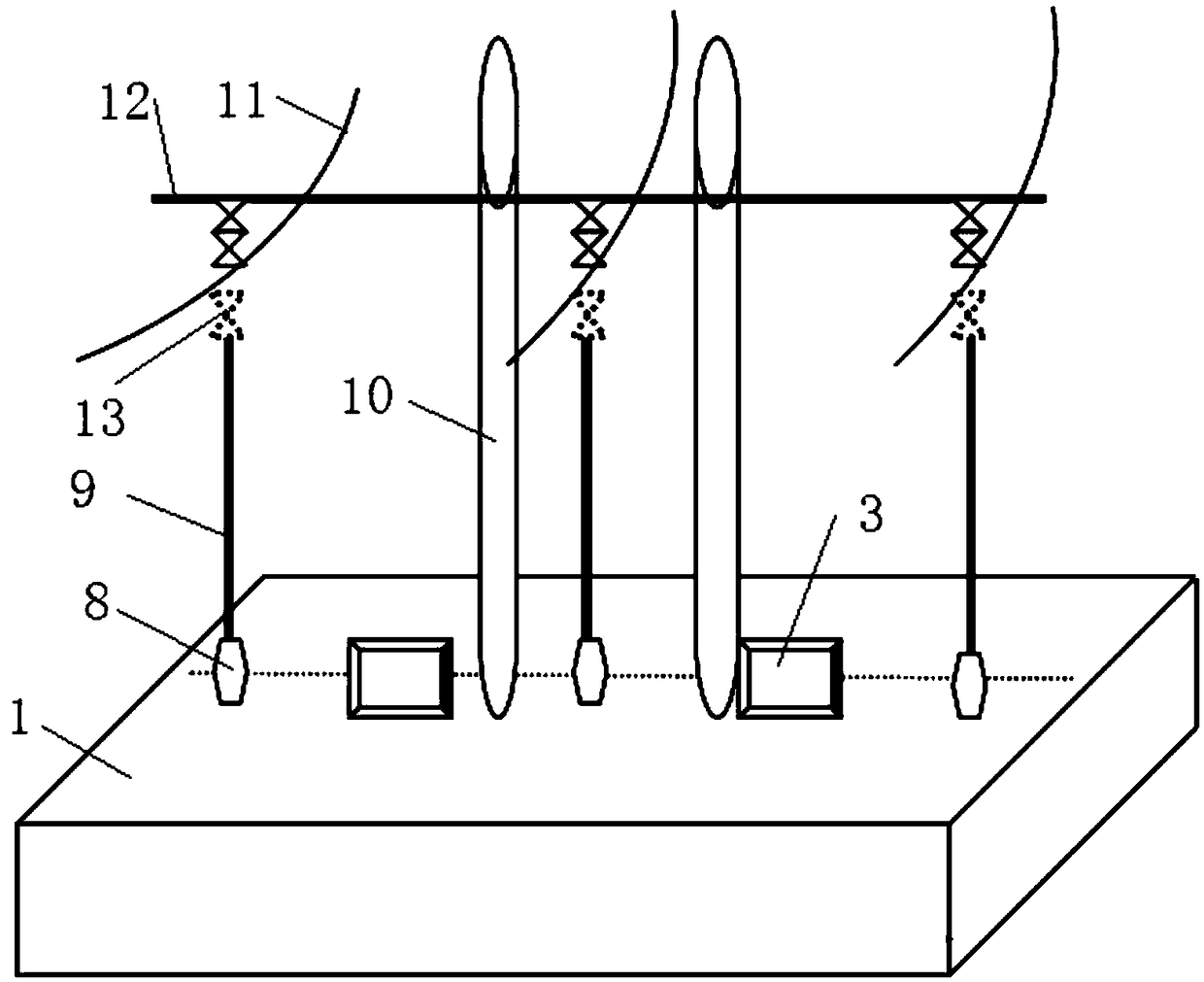

Assembled manual picking assisting device

The invention relates to the technical field of fruit picking apparatuses, in particular to an assembled manual picking assisting device. The device comprises an enclosure spliced bottom plate and a lifting cabin placed in an enclosure area of the enclosure spliced bottom plate; each splicing part of the enclosure spliced bottom plate is provided with a base, a supporting rod is arranged on each base, the bottom of each supporting rod is fixedly connected with a rotating mechanism, a guiding rod is hinged to the top of each supporting rod, a hoisting rod is inserted in the top of each guidingrod, a positioning rod is inserted in the top of each hoisting rod, the guiding rods and the corresponding inserted hoisting rods are fastened through locking mechanisms, and the hoisting rods and thecorresponding inserted positioning rods are fastened through locking mechanisms; the lifting cabin is connected with the positioning rods through lifting mechanisms; the device further comprises spliced sleeves sleeving the hoisting rods, and the spliced sleeves are connected with the hoisting rods through up-down moving mechanisms; the manual picking assisting device assists picking personnel inconducting picking on fruit trees, the picking personnel are prevented from falling from the trees, and the life safety of the picking personnel is ensured.

Owner:白铭

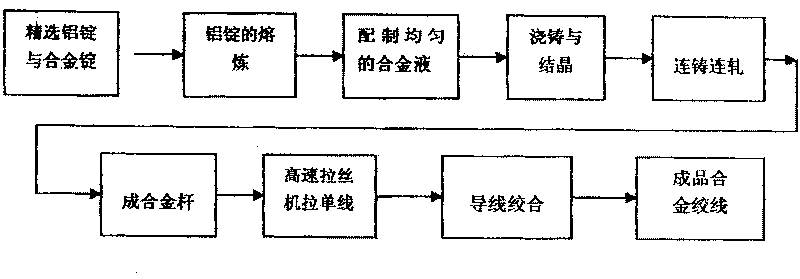

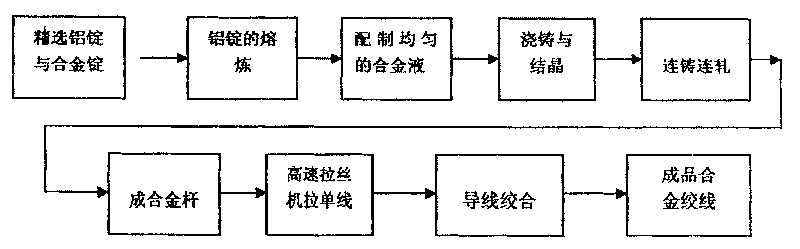

Method for manufacturing high-strength aluminium-magnesium-slicon alloy wire

ActiveCN101200783BControl UniformityGuaranteed uniformityTemperature control deviceMetal rolling arrangementsSpectrum analyzerShaft furnace

The invention relates to a manufacturing method of Al-Mg-Si alloy line. The technological process is: selecting excellent aluminum ingot and putting the aluminum ingot in a vertical furnace to be melted; adding magnesium, silicon and iron; implementing the alloying treatment on aluminum liquid in a tilting holding furnace; using solid covering flux to cover the surface of the aluminum liquid afterthe refining through refining agent and standing for more than 30m; using a spectrum analyzer to detect main elements and regulating when the content is deviated; slowly dumping the aluminum solutionby the tilting holding furnace; adding 0.03 to 0.5 percent of aluminum boron alloys when the dumped aluminum solution is refined through a chute and a continuous scouring device outside of the furnace; continuously casting with an aluminum alloy caster that is composed of an H-type wheeled crystal wheel into the aluminum alloy ingot; putting the aluminum alloy ingot in a two-roller with three-roller novel combined aluminum alloy continuous mill to mill the ingot into a Al-Mg-S alloy bar. The aluminum alloy bar is arranged at a sliding wire drawing machine to be drawn into aluminum alloy product line with required diameter and be stranded into line. The invention has the advantages of both ensuring the high strength and improving the conductivity simultaneously. The conductivity can reachto 53 percent IACS and the strength reaches to 315MPa.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

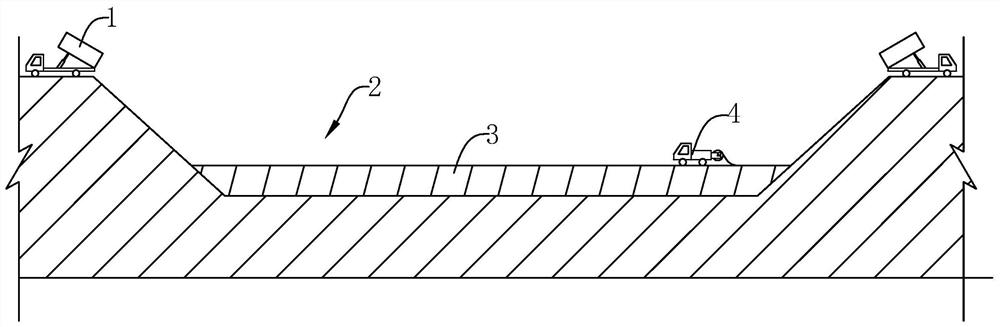

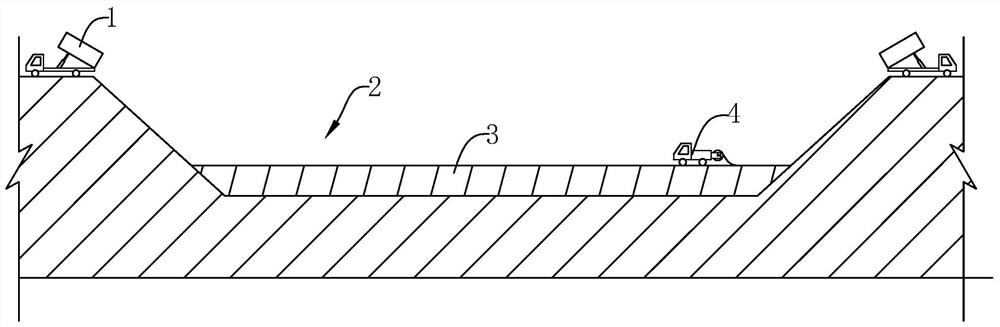

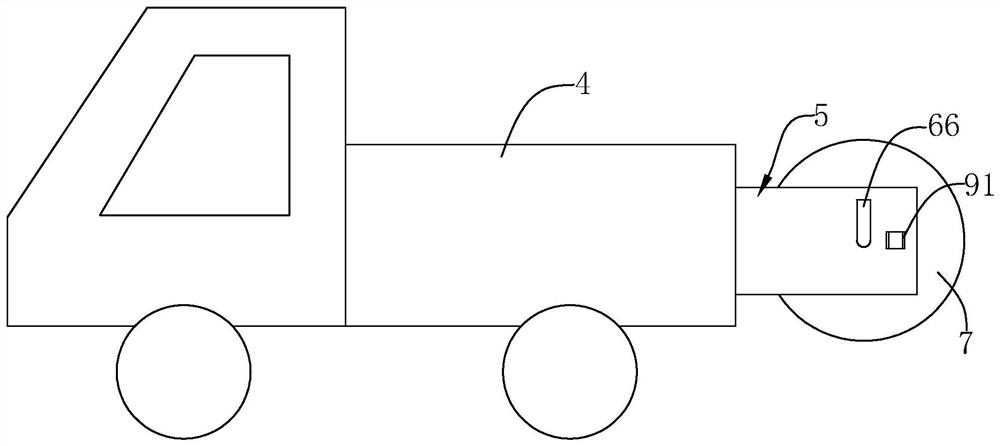

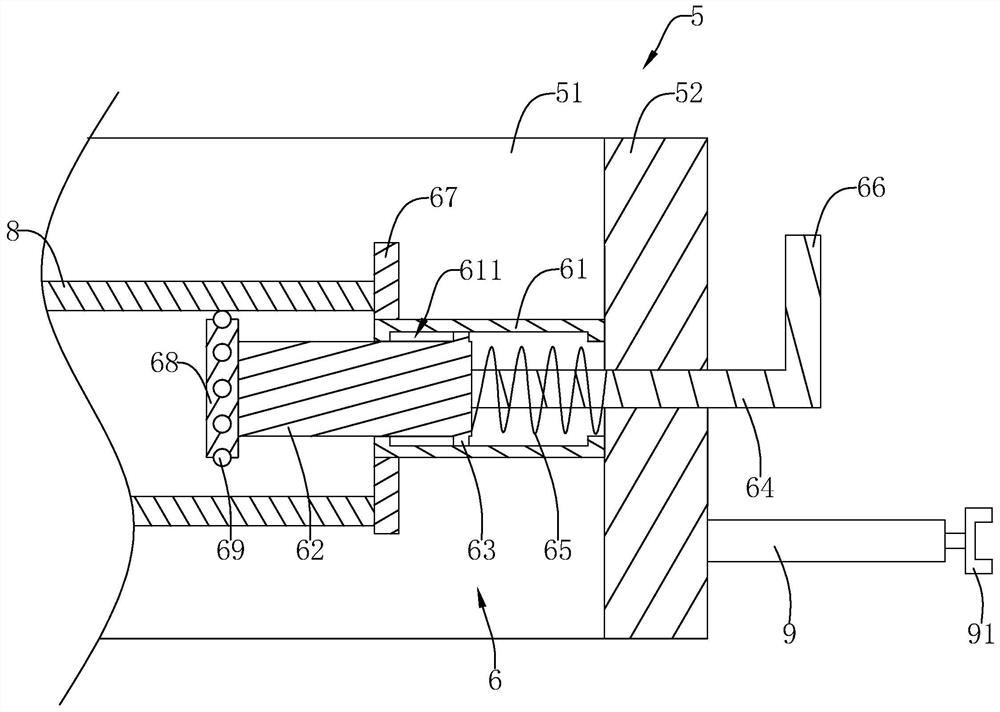

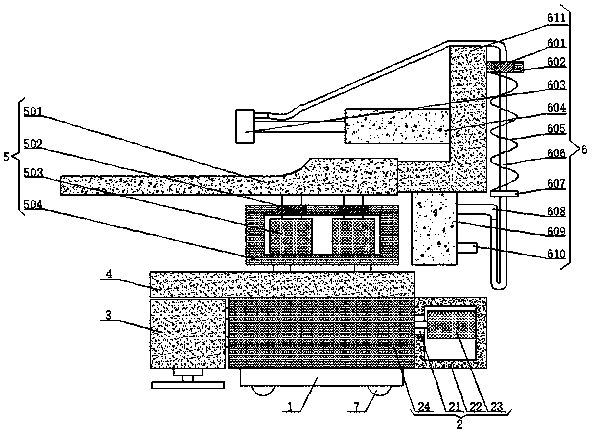

Landfill operation paving method for refuse landfill

ActiveCN112453006AEnsure safetyImprove efficiencyLandfill technologiesSolid waste disposalEnvironmental engineeringEnvironmental protection

The invention relates to the field of refuse landfill, in particular to a landfill operation paving method for a refuse landfill. The landfill operation paving method comprises the following construction steps that S1, refuse is dumped at at least two opposite positions on the upper portion of the landfill to enable the refuse to slide towards the bottom of the landfill along a slope of the landfill; S2, the refuse piled on the slope of the landfill is moved to the bottom of the landfill; S3, the refuse is paved along the bottom of the landfill to form a refuse layer; and S4, an odor-resistantlayer is laid on the surface of the refuse layer through an operation vehicle. The landfill operation paving method has the effects of improving the construction efficiency and reducing potential safety hazards.

Owner:北京银都建设工程集团有限公司

Maintenance and clearing auxiliary mechanism for concrete stirring machine

ActiveCN108746118AEasy to liftEasy maintenance and repairHollow article cleaningLifting devicesSurface mountingPulp and paper industry

The invention discloses a maintenance and clearing auxiliary mechanism for a concrete stirring machine, and relates to the technical field of concrete stirring machines. The maintenance and clearing auxiliary mechanism comprises a bottom plate. A horizontal-moving mechanism is mounted on the upper surface of the bottom plate, a stabilizing mechanism is mounted on the left side of the horizontal-moving mechanism, a conducting mechanism is mounted on the horizontal-moving mechanism, a lifting mechanism is mounted above the conducting mechanism, and a clearing mechanism is mounted on the right side of the lifting mechanism. According to the maintenance and clearing auxiliary mechanism for the concrete stirring machine, a lifting plate can be better driven to rise through extending of the telescopic ends of electric hydraulic pushing rods, accordingly, a stirring hopper is lifted up, the effect that the stirring hopper is lifted and dragged out by the maintenance and clearing auxiliary mechanism is achieved, detecting personnel better maintain and overhaul a control and transmission system of the stirring machine, and the situation that when detection is conducted, the space is too small, and consequently, the efficiency is affected is avoided; and through operation of a strong water suction pump, a water body is pumped into an annular spraying head and sprayed annularly, and thusthe using effect of the maintenance and clearing auxiliary mechanism is improved.

Owner:德州市洛泰商贸有限公司

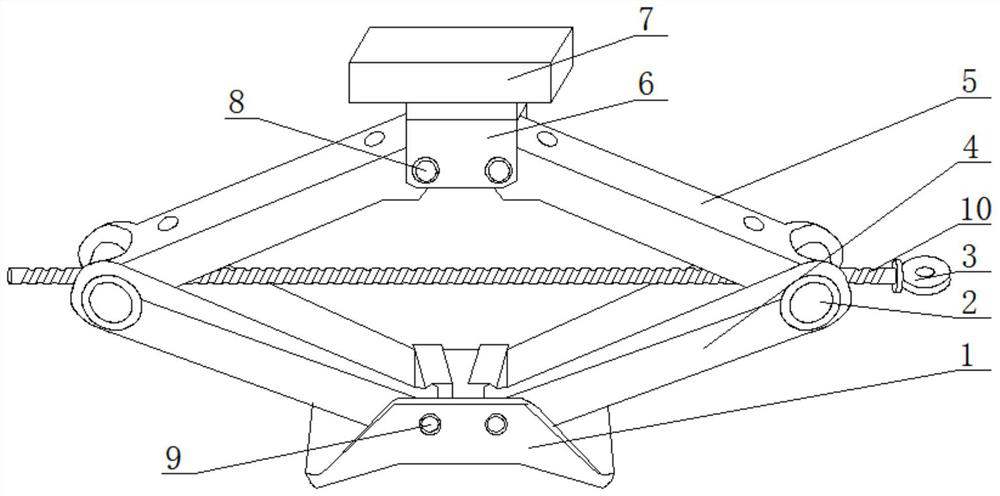

Jack with anti-toppling structure

Owner:西安发威电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com