Cyclic type mechanical conveying device for steel balls

A mechanical transportation and circulation technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reducing the amount of steel balls, wasting electric energy, and the shape of steel balls accumulates deviations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The circulation type steel ball mechanical transportation device provided by the present invention is applied in the waste heat boiler of the steel ball dedusting submerged arc furnace for transporting the steel balls.

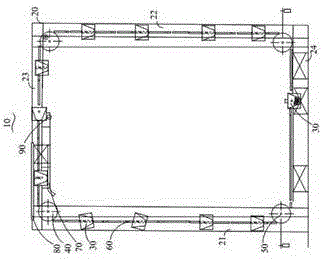

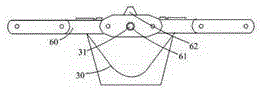

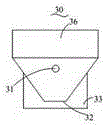

[0013] Such as figure 1 and figure 2 The circular steel ball mechanical transport device 10 includes a support frame 20, a steel ball transport bucket 30, and a driving wheel 40 fixed on the support frame 20, a driven wheel 50, a double chain 60, a fine adjustment correction plate 70, and a thick correction rod 80 , Mechanical unloading retaining wheel 90.

[0014] The support frame 20 includes a left vertical support frame 21, a right vertical support frame 22, an upper transverse support frame 23, and a lower transverse support frame 24. There is at least one driving wheel 40, and at least three driven wheels 50. The driving wheel 40 and the driven wheel 50 are all fixed on the support frame 20, for example, at the crossing position between the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com