Method for high-notch blasting demolition of thin-wall reinforced concrete chimney

A reinforced concrete and incision technology, applied in blasting, building maintenance, building types, etc., can solve the problems of the uncertainty of the exact direction of the chimney, the uncontrollable dumping length, etc., to improve blasting safety and controllability, and reduce dumping coverage. range, the effect of increasing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to more understand the technical content of the present invention, the specific embodiments are specifically illustrated and described in the accompanying drawings.

[0050] In the present disclosure, various aspects of the invention are described, and the accompanying embodiments are shown in the drawings. Embodiments of the present disclosure do not have to be bound to all aspects of the invention. It should be understood that the various concepts and embodiments described above, and those described in more detail below can be carried out in a variety of ways to remove thin-walled reinforced concrete chimneys in many ways, because the present invention The concepts and examples disclosed are not limited to any embodiment. In addition, some aspects disclosed thereof may be used singly or in any suitable combination of other aspects disclosed in the present invention.

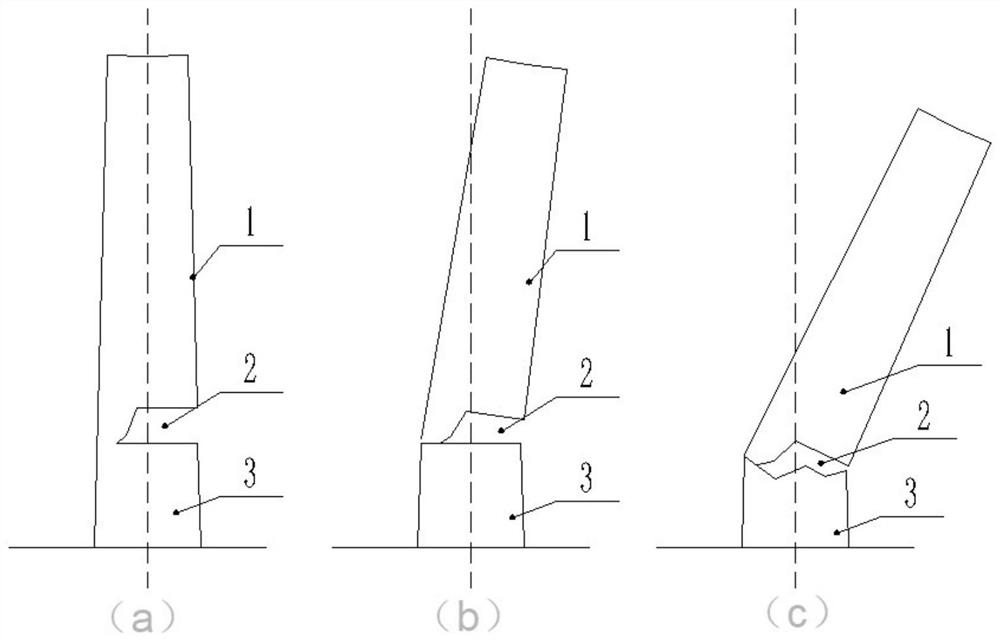

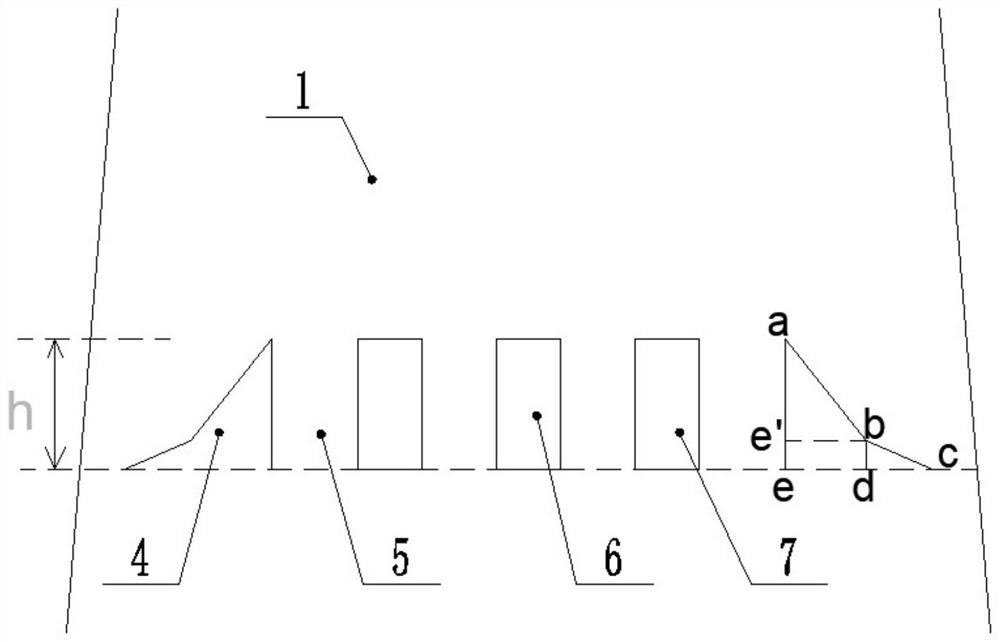

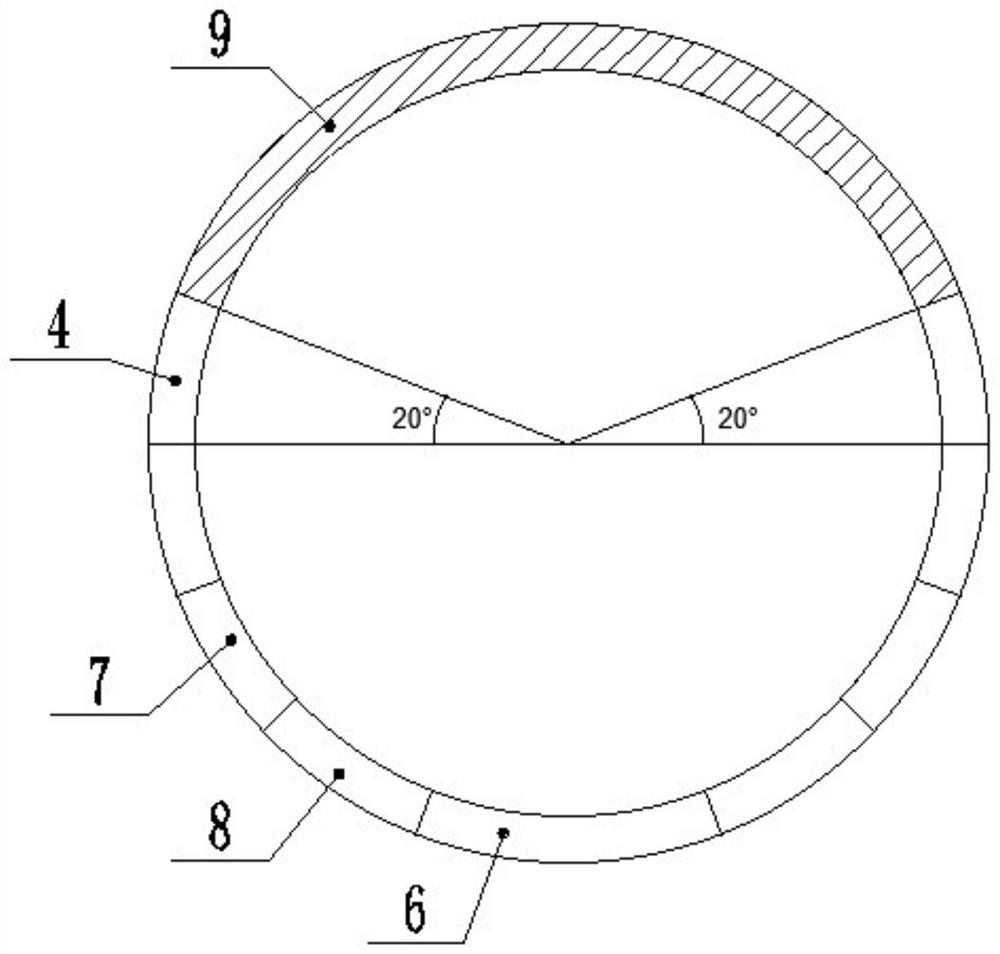

[0051] When using a high-cut blasting to remove the high chimney, the directional window is in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com