An all-electric ride-on pallet truck

A pallet truck and ride-on technology, which is applied in the direction of lifting devices, etc., can solve the problems of slow efficiency, easy overturning, dangerous transportation of fragile goods, etc., and achieves the effect of improving efficiency, saving manpower and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

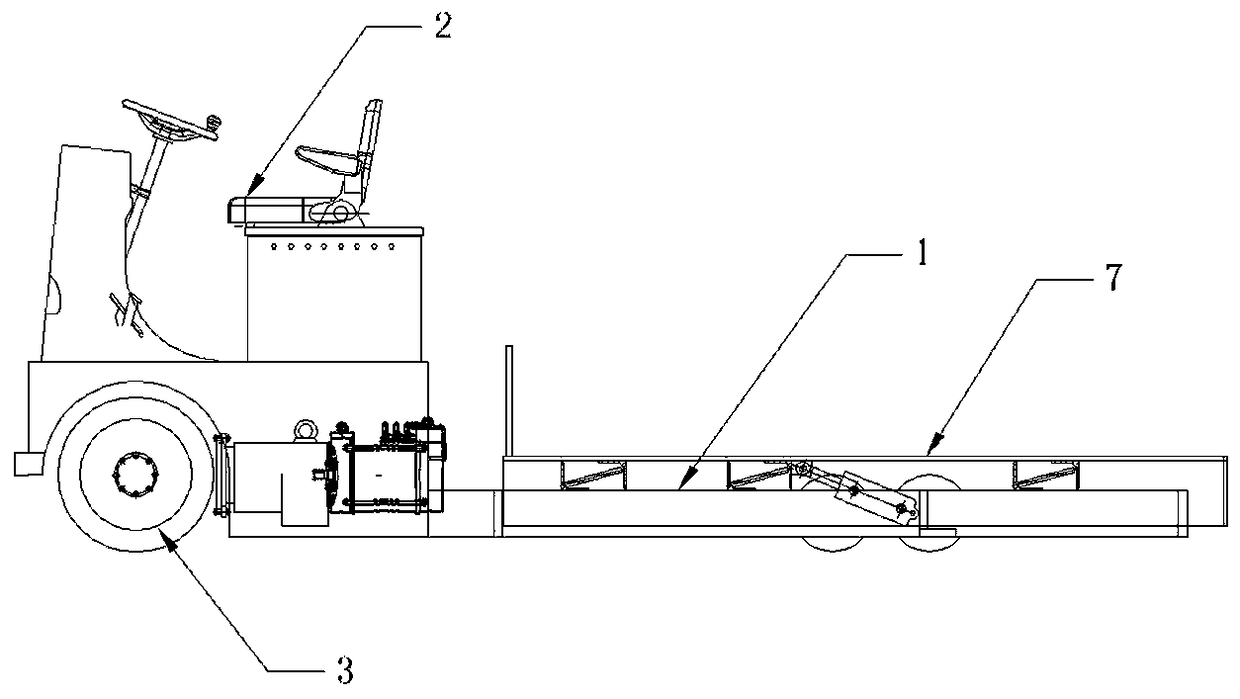

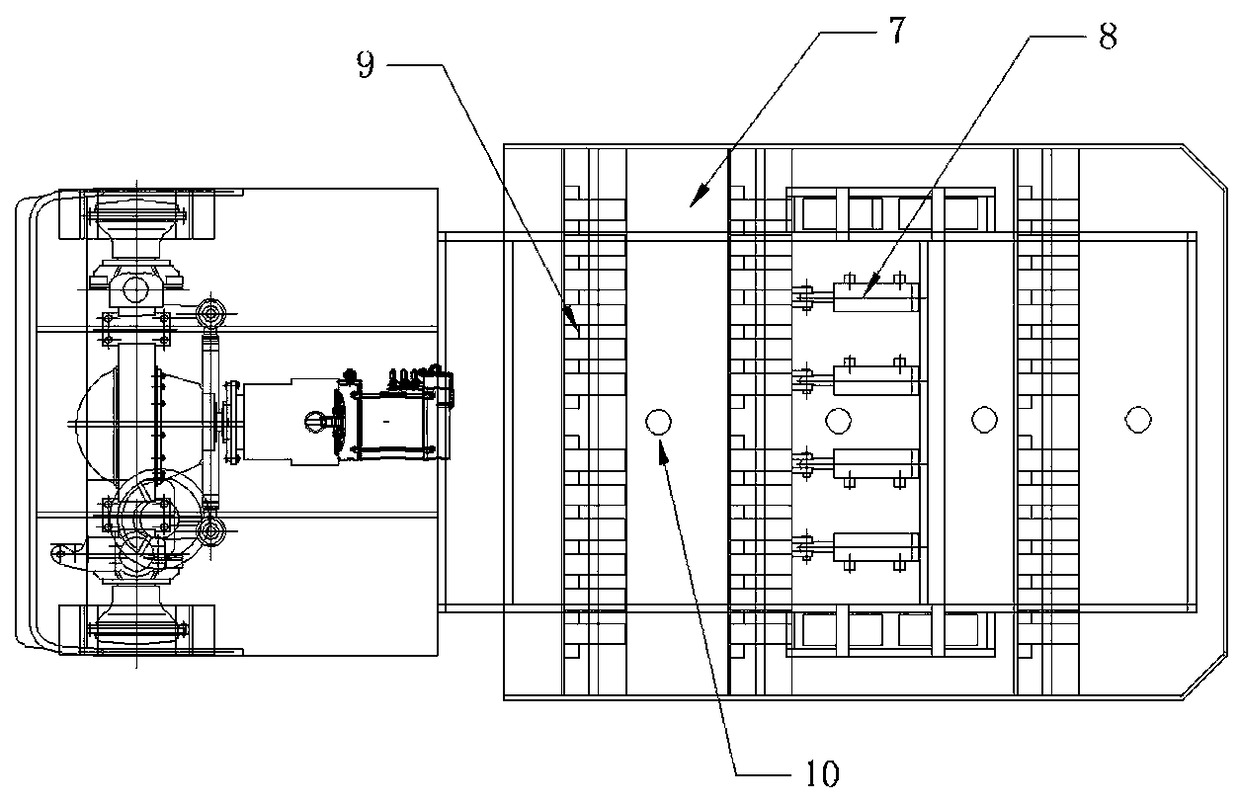

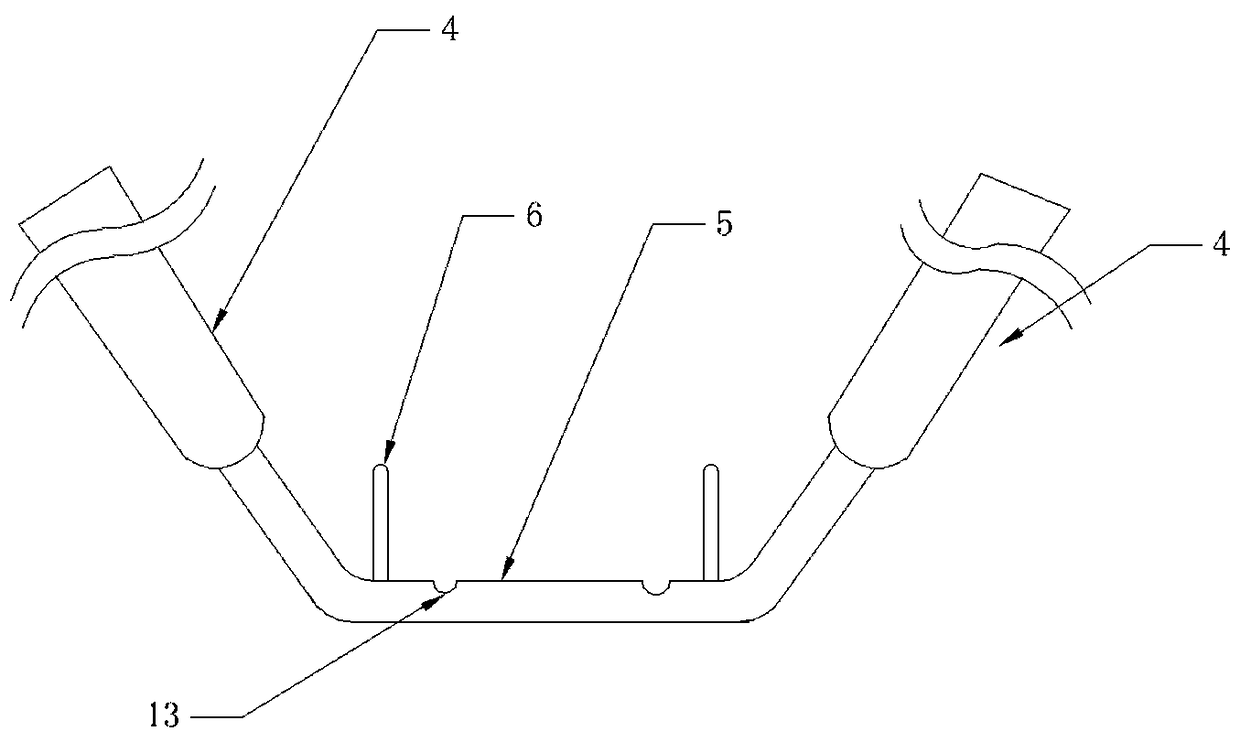

[0023] Such as Figure 1-Figure 4 A kind of all-electric sit-on pallet truck shown, comprises body 1, and the front end of body 1 is provided with driver's cab 2 and control room, and body 1 is provided with drive device, and drive device includes power supply, drive motor, controls drive motor The operation button is arranged in the control room; the driving motor is respectively connected to the power supply and the driving wheel 3 under the body 1; a pallet lifting mechanism is respectively arranged on both sides of the body 1, and the lifting mechanism includes a lifting cylinder 4, a supporting plate 5 and a The vertical fixing bar 6 on the supporting plate 5 is connected with the lifting cylinder 4 on both sides of the supporting plate 5; a propulsion device for pushing the pallet is installed on the supporting plate 5.

[0024] In this embodiment, a bottom plate 7 is installed on the vehicle body 1, and the bottom plate 7 is provided with a delivery wheel 8 for the tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com