Steel ball dust removal type submerged arc furnace waste heat boiler for easy recovery of steel balls

A waste heat boiler and submerged arc furnace technology, applied in the field of waste heat boilers, can solve problems such as loss, waste of materials, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

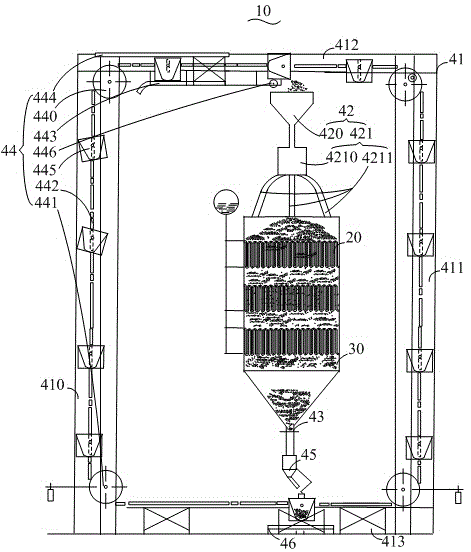

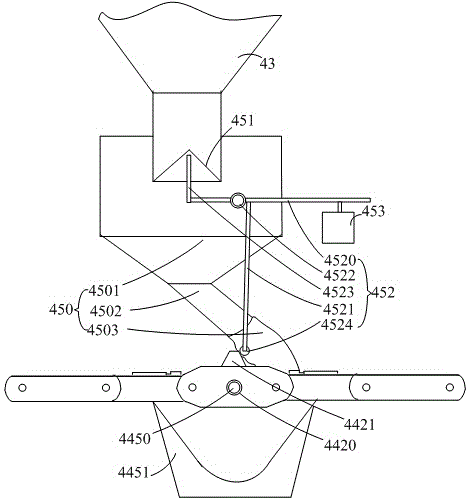

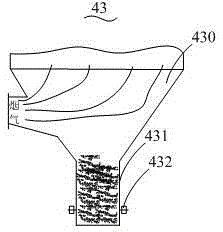

[0013] Please see also figure 1 , the steel ball dedusting submerged arc furnace waste heat boiler 10 that is easy to recover steel balls includes a boiler heating surface 20 composed of serpentine tube groups, a boiler flue gas passage 30 with a sealed passage formed around the boiler heating surface 20, a circulating steel column mechanical cleaning As for the ash device 40, the top of the boiler flue gas passage 30 is provided with a furnace roof, and the bottom of the boiler flue gas passage 30 is provided with a furnace bottom ash hopper.

[0014] The circulating steel column mechanical dust removal device 40 includes a supporting frame 41 , a steel ball spreading device 42 , a steel ball separating and collecting device 43 , a circulating steel ball mechanical transport device 44 and a steel ball air lock loading device 45 .

[0015] The support frame 41 is erected around the boiler flue gas channel 30, and the support frame 41 includes a left vertical support frame 410,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com