Steel-ball-dedusting type submerged-arc-furnace waste heat boiler capable of keeping balance of steel ball transport bucket

A waste heat boiler and transport bucket technology, applied in the field of waste heat boiler, can solve the problems of reducing the cleaning effect, shape deviation, waste of electric energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

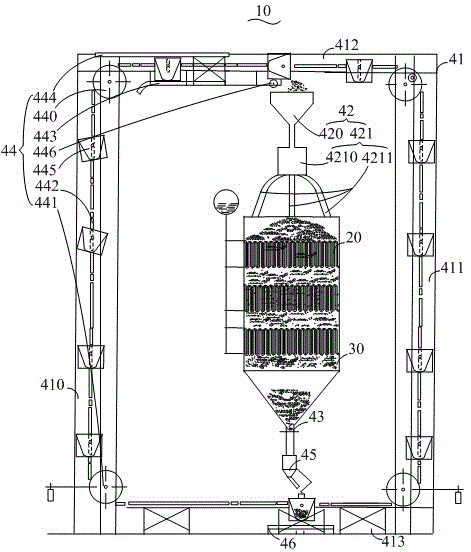

[0014] Please see also figure 1 , the steel ball dedusting submerged arc furnace waste heat boiler 10 that keeps the balance of the steel ball transport bucket includes a boiler heating surface 20 composed of serpentine tube groups, a boiler flue gas channel 30 with a sealed passage formed around the boiler heating surface 20, and a circulating steel column Mechanical ash cleaning device 40, a furnace roof is installed on the top of the boiler flue gas passage 30, and a furnace bottom ash hopper is installed at the bottom of the boiler flue gas passage 30.

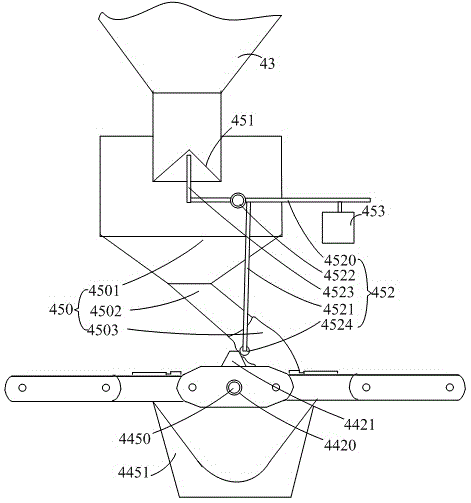

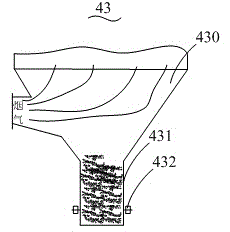

[0015] The circulating steel column mechanical dust removal device 40 includes a supporting frame 41 , a steel ball spreading device 42 , a steel ball separating and collecting device 43 , a circulating steel ball mechanical transport device 44 and a steel ball air lock loading device 45 .

[0016] The support frame 41 is erected around the boiler flue gas channel 30, and the support frame 41 includes a left vertical supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com