Steel ball dust removal type submerged arc furnace waste heat boiler to keep the steel ball transport bucket balanced

A waste heat boiler and transport bucket technology, applied in the field of waste heat boilers, can solve the problems of deviation in shape, waste of electric energy, reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

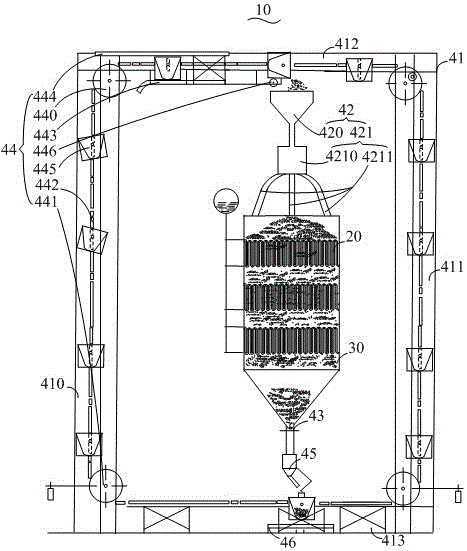

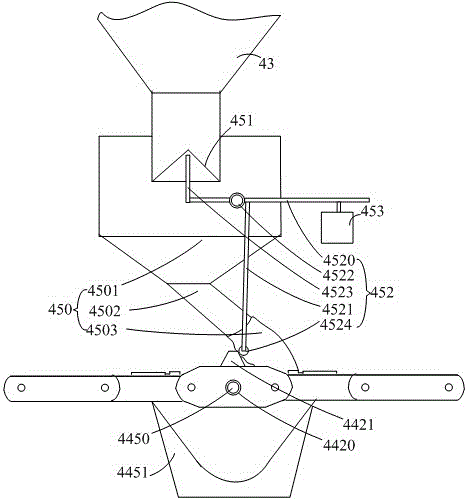

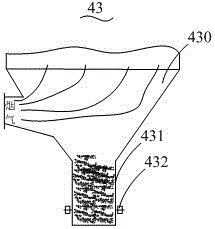

[0014] The circulating steel column mechanical dust removal device 40 includes a supporting frame 41 , a steel ball spreading device 42 , a steel ball separating and collecting device 43 , a circulating steel ball mechanical transport device 44 and a steel ball air lock loading device 45 .

[0015] The support frame 41 is erected around the boiler flue gas channel 30, and the support frame 41 includes a left vertical support frame 410, a right vertical support frame 411, an upper horizontal support frame 412, a lower horizontal support frame 413, a left vertical support frame 410, a right The vertical support frame 411 is correspondingly located on the left and right sides of the boiler flue gas passage 30 , and the upper transverse support frame 412 and the lower transverse support frame 413 are respectively located on the top and bottom of the boiler flue gas passage 30 .

[0016] The steel ball spreading device 42 is arranged on the furnace roof of the boiler flue gas passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com