Coil induction type contact member

A contact, inductive technology, applied in the direction of transformer/inductor coil/winding/connection, electrical components, transformers, etc., can solve the problems of inability to disassemble, inconvenient to use, etc., to ensure convenience, wide range of use, and huge economy. The effect of value and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

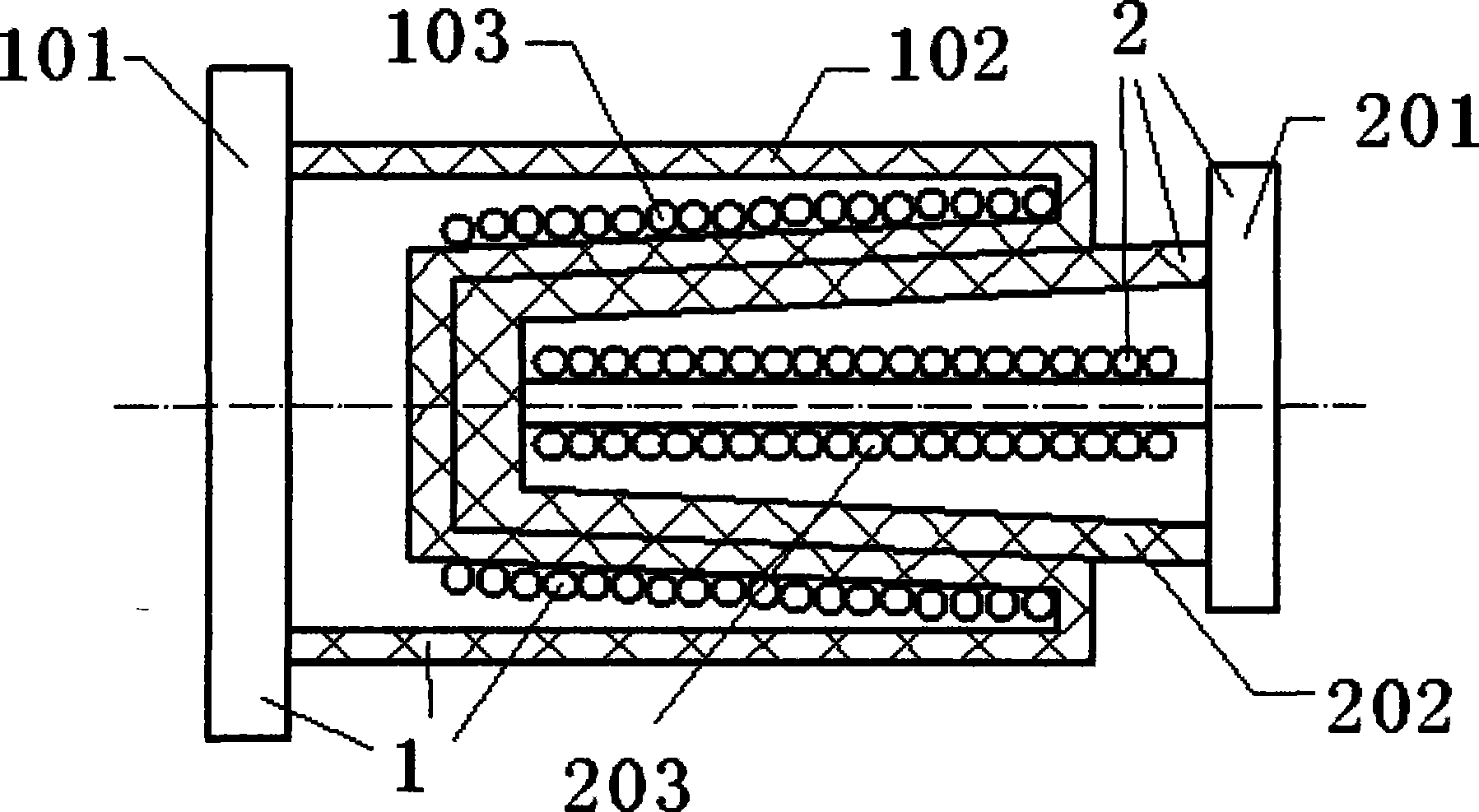

[0018] A coil induction contact, which includes a hole contact (1) and a pin contact (2); it is characterized in that: the hole contact (1) and the needle contact (2) in the coil induction contact ) uses physical insulation and transmits energy through electromagnetic induction.

[0019] The hole contact (1) in the coil induction contact specifically includes the following structures: hole seat (101), hole housing (102), electromagnetic induction hole structure (103); wherein: hole housing One end of (102) is fixedly connected with the hole seat (101), and the other end has a recessed hole structure; the electromagnetic induction hole structure (103) is arranged inside the hole housing (102); the hole seat (101) and The inner cavity of the slot housing (102) fixedly connected thereto together forms an internally closed cavity.

[0020] The needle contact (2) in the coil induction contact specifically includes the following structures: a needle base (201), a needle housing (20...

Embodiment 2

[0025] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

[0026] The slot housing (102) and the needle housing (202) in the coil induction contact piece are specifically made of a magnetically permeable material covered with an electrical insulating layer on the outside. The material of the electric insulating layer coated on the surface of the hole housing (102) and the needle housing (202) exposed to the outside in the coil induction contact piece is made of plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com