Injection molding encapsulation die structure

A technology of injection molding and overmolding, which is applied in the field of injection molding and overmolding mold structure, can solve the problems of reducing the service life of products, reducing the rate of finished products, and increasing the cost of leaving the factory, and achieving the effects of preventing falling off, reducing the cost of leaving the factory, and increasing the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

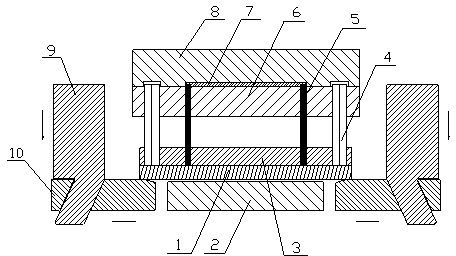

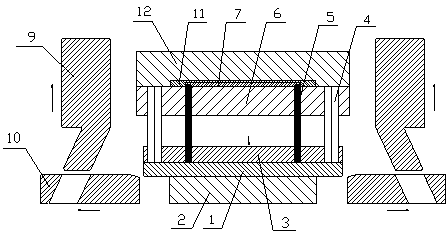

[0012] Such as figure 1 and figure 2 An injection overmolding mold structure is shown, including a support plate 2, a backing plate 1 is provided on the support plate 2, a base 3 is provided on the backing plate 1, a male mold core 6 is arranged above the base 3, and the male mold core 6 is fixed In the horizontal direction, the base 3 is provided with a return needle 4 and a movable core 5 passing through the male core 6, and the base 3 on both sides of the support plate 2 is provided with a laterally moving slider unit. The first female mold core 6 is provided with a first female mold core 8 and a second female mold core 9, and the first female mold core 8 is provided with a cavity to cooperate with the return pin 4; the slider unit includes a slider 10 , the slide block 10 is provided with a chute, the chute is provided with a slant lock 9, the height of the slide block 10 is higher than the height of the support plate 2; the return pin 4 is two; the movable core 5 for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com