Automatic holder sheathing machine and technological method thereof

A technology of automatic package and process method, which is applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing factory cost and failure to realize production automation, and achieve the effect of reducing burden, reducing factory cost and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

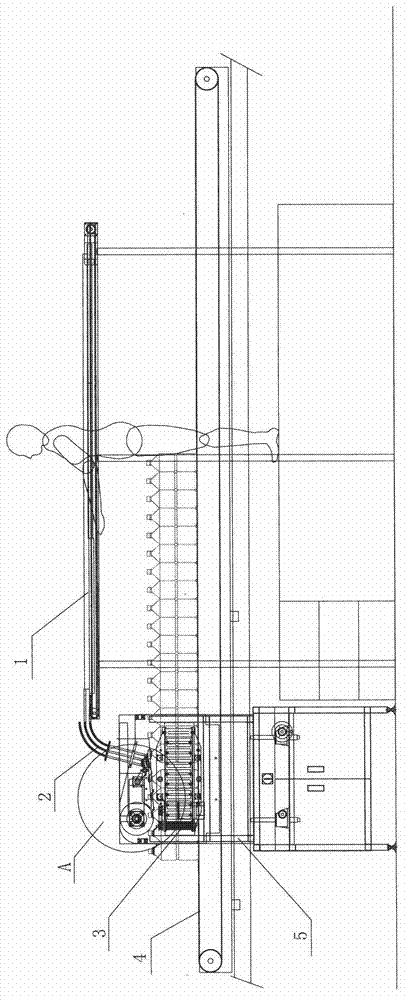

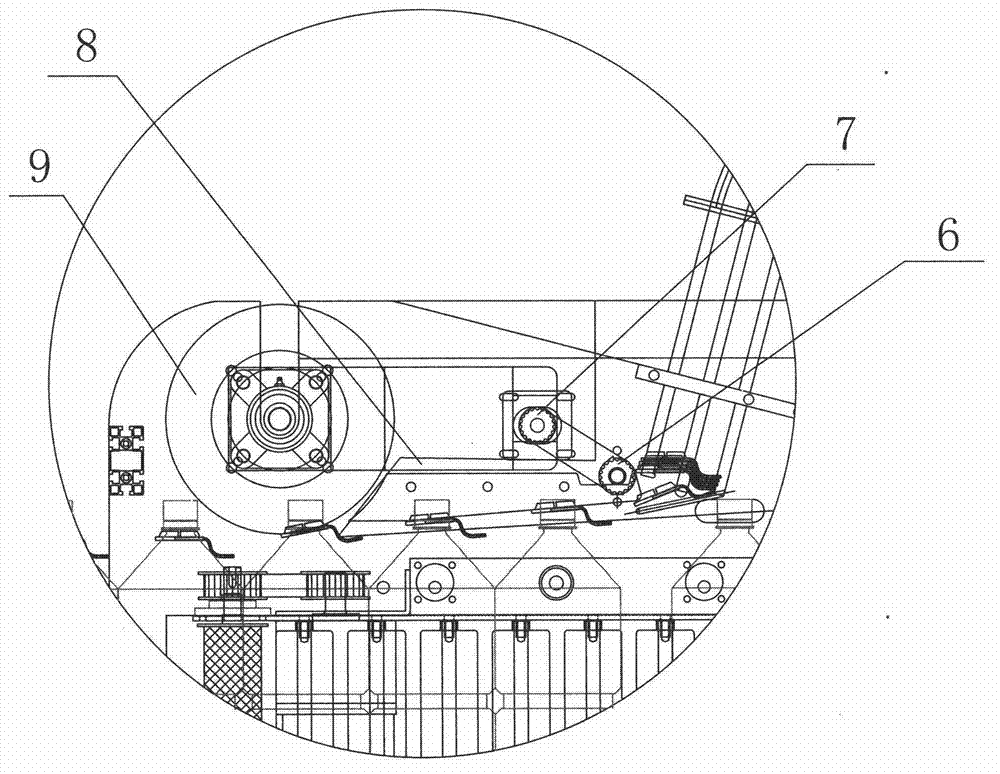

[0019] Such as figure 1 and figure 2 A kind of buckle automatic assembling machine shown, comprises conveyor belt 4, is provided with bracket 5 on conveyor belt 4, and the top of described conveyor belt 4 is provided with buckle conveyor belt 1, and the outlet end of buckle conveyor belt 1 is provided with buckle guide groove 2 , in the forward direction of the conveyor belt at the outlet end of the buckle guide groove 2, there are bead 8 and pressure wheel 9 successively, and the pressure wheel motor drives the pressure wheel 9 to rotate; the outlet end of the buckle guide groove 2 is provided with a buckle dial 6 and The position sensor, the buckle dial 6 is driven by the servo motor 7, and the position sensor and the servo motor 7 are connected to the PLC system; the bottom of the bead 8 is an inclined plane; There is a bottle body clamping conveyor 3; the bottle body clamping conveyor 3 includes a clamping bracket, and a conveying roller is arranged on the clamping brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com