Die opening/closing structure system used for injection mold

A technology of injection moulding and moulding, applied in the direction of coating, etc., can solve problems such as dangers caused by machinery, and achieve the effect of eliminating the phenomenon of shoveling glue, improving the qualification rate and reducing the cost of leaving the factory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

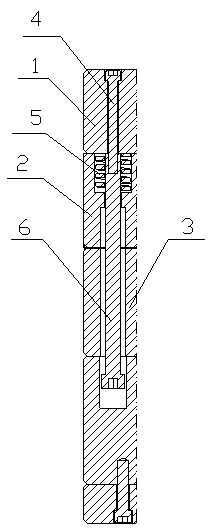

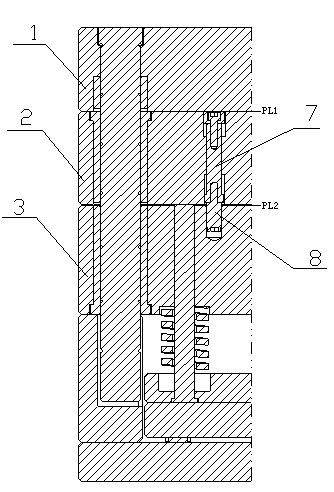

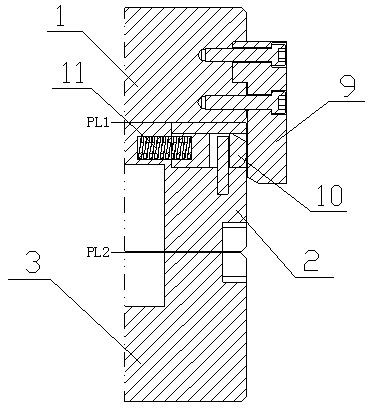

[0014] Such as figure 1 , figure 2 , image 3 with Figure 4 A mold opening and closing structure system for an injection mold is shown, including a panel 1, an A board 2 and a B board 3, and the system also includes a small pull rod mechanism, a rubber plug mechanism, a push block mechanism, and a slider mechanism. The described small pull rod mechanism includes the pull rod screw 4 installed in the panel 1, the pull rod screw 4 and the small pull rod 6 that runs through the A board 2 and the B board 3, and the small pull rod spring 5 in the A board 2 on the outside of the small pull rod 6. There is a limit step in the plate 2 that cooperates with the head of the small pull rod 6; the rubber plug mechanism includes a rubber plug rod 7 and a rubber plug 8 fixed on the rod of the rubber plug rod 7, and the head of the rubber plug rod 7 is connected with the A plate 2, the rubber plug 8 is inserted into the hole of the B board 3; the push block mechanism includes a push bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com