Method and apparatus for producing a non-uniform coating on a substrate

A coating device and coating technology, which is applied to the device for coating liquid on the surface, coating, textile and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0030] Objects and advantages of the present invention are further illustrated by the following non-limiting examples. The particular materials and amounts thereof, as well as other conditions and details, recited in these examples should not be construed to unduly limit this invention. All parts, percentages, ratios, etc. in the examples, as well as in the remainder of the specification, are by weight unless otherwise indicated.

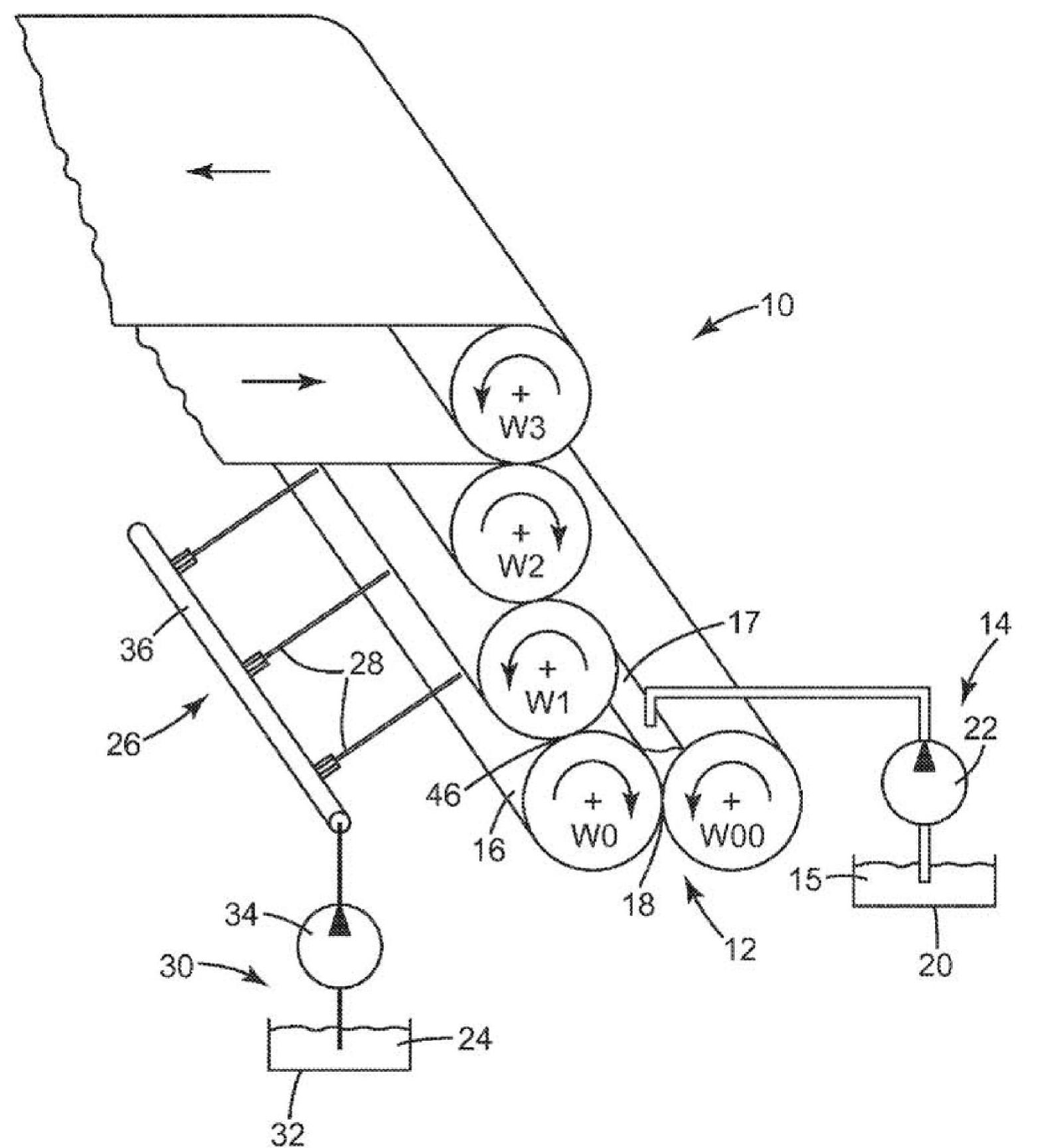

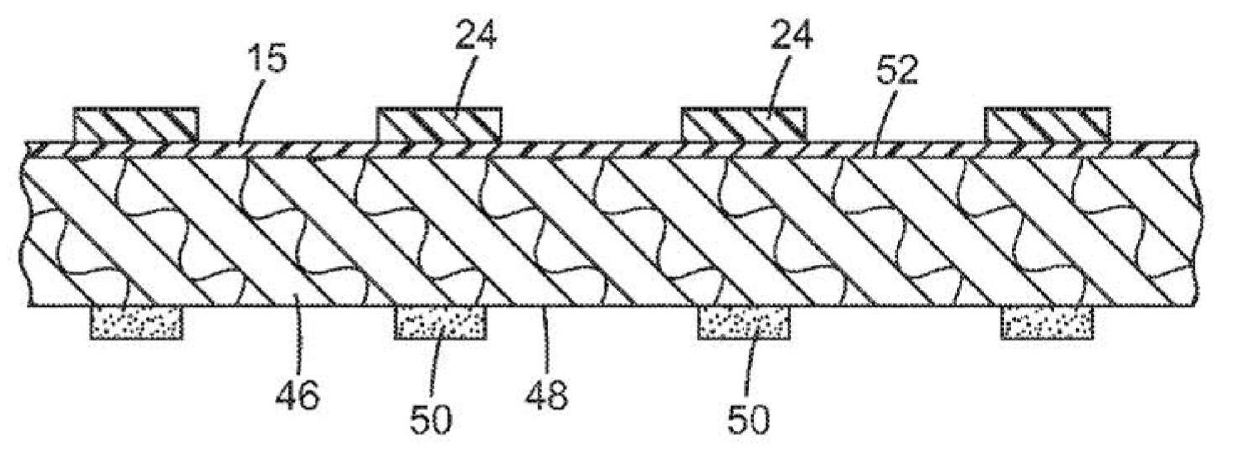

[0031] in with figure 1 Basecoating was performed on a similar five-roll coater to illustrate the image 3 A one-step roll coating process for producing a coated substrate with a non-uniform low adhesion backside (LAB) coating on the second major surface of a paper substrate is shown. Coat grape-colored paper substrates with a non-uniform LAB coating since bands of this coating material are often visible on darker colored papers. An adhesive coat weight of 0.75 grams per square foot (gsf) was applied to the first major surface of the paper in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com