Ball valve spool and production method thereof

A production method and valve core technology, which are applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as low work efficiency, short service life, and rising material costs, so as to improve work efficiency and reduce production processes. , the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

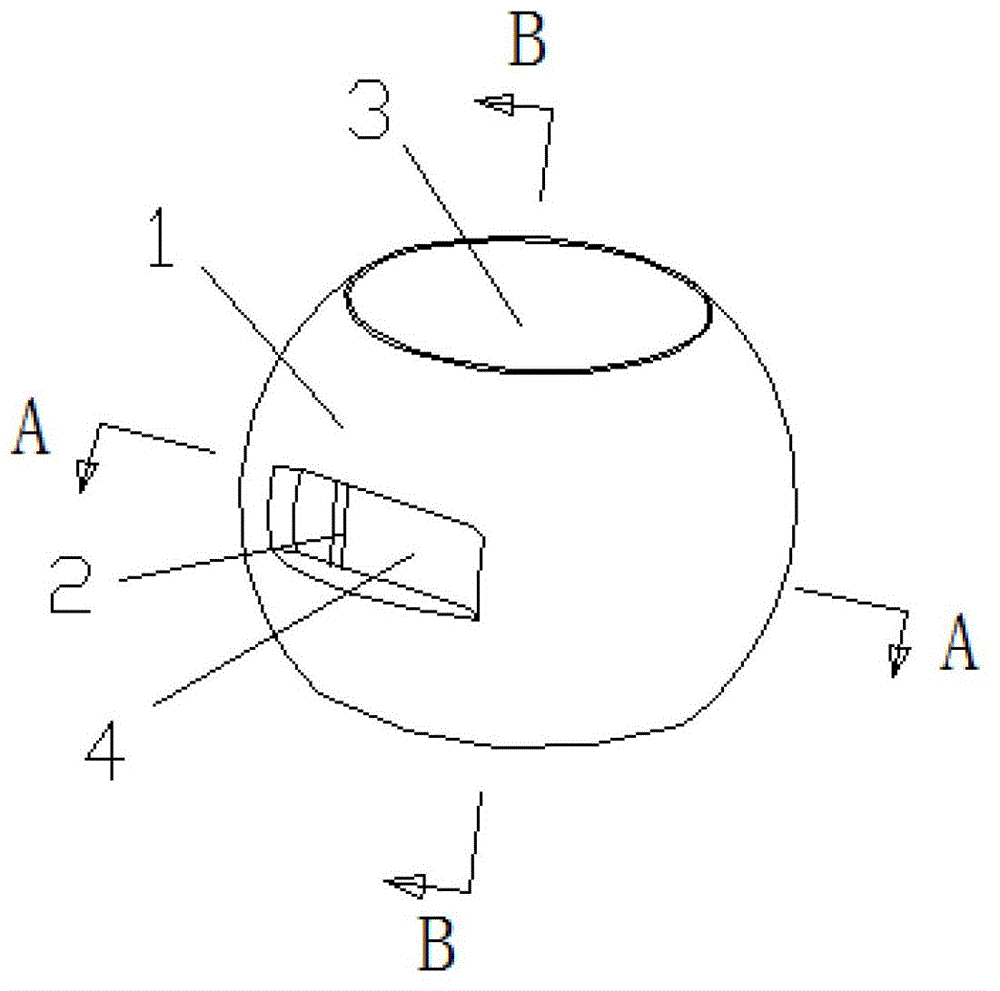

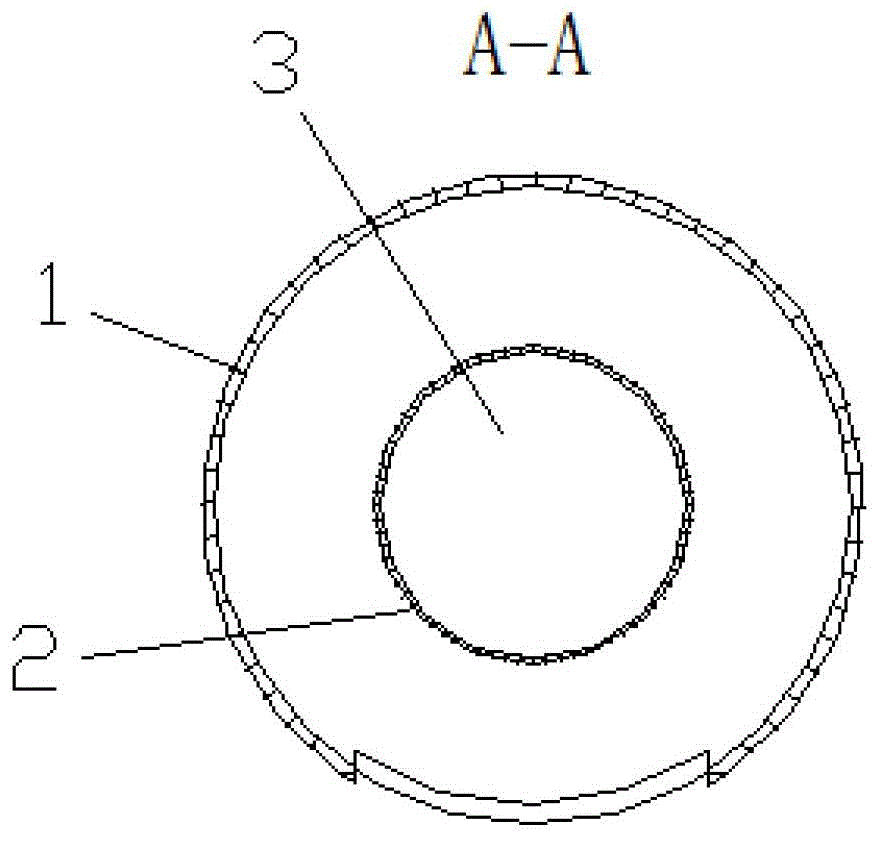

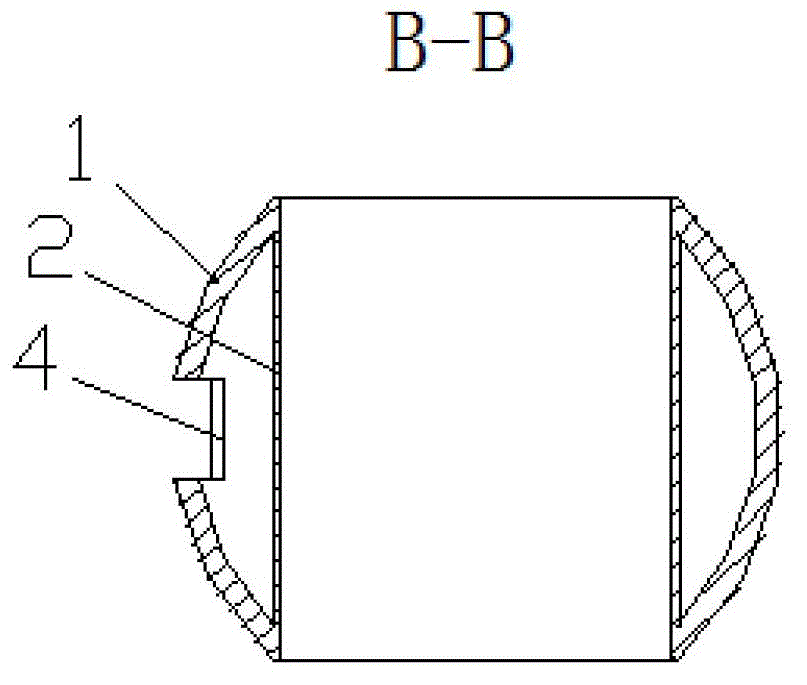

[0024] see Figure 1-Figure 5 As shown, a ball valve spool includes a hollow outer sphere 1 and an inner straight pipe 2. The inside of the outer sphere 1 is provided with a through hole 3, and the cross-sectional shape of the upper and lower ends of the through hole 3 is They are mutually parallel and equal circles, and the outer sphere 1 is provided with a notch 4 that runs through the inside and outside of the outer sphere; the inner straight tube 2 is fitted into the through hole 3 of the outer sphere 1 and the junction is tight fit.

[0025] Further, the above-mentioned inner straight pipe 2 and the through hole 3 of the outer spherical body 1 are transition fit.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com