Inlay type combined die structure

A combination of die and die technology, applied in the field of die structure, can solve the problems of easily damaged electrodes, scrapped dies, explosive dies, etc., and achieve the effects of avoiding stress concentration, reducing factory cost and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

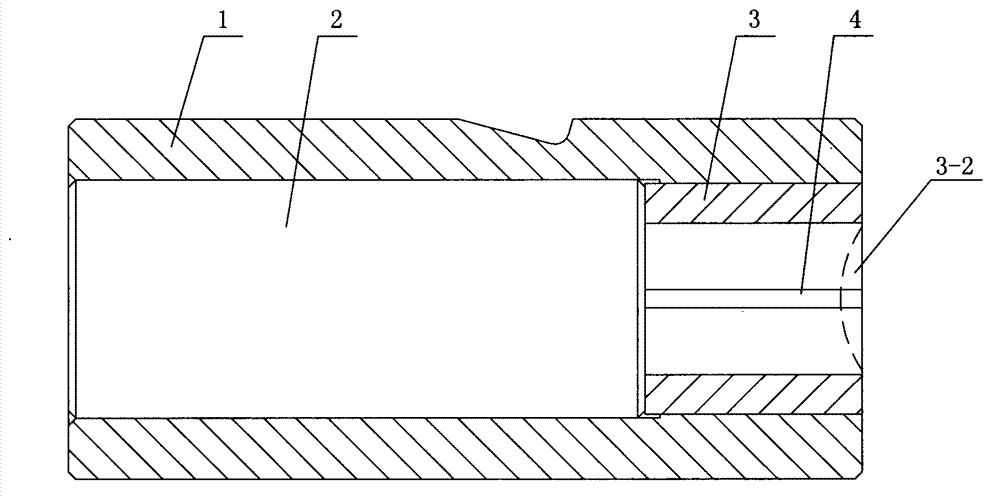

[0017] Such as figure 1 , Figure 5 with Image 6 An inlaid combined die structure is shown, including a die cover 1, a rear pad 2 is provided inside the die cover 1, a die body 3 is provided on the rear pad 2 inside the die cover 1, and a forming Groove 3-2, is provided with inlaid piece slot hole 3-1 in molding groove 3-2, is provided with inlaid piece 4 in the inlaid piece slot hole 3-1; The upper molding surface of described molding groove 3-2 is Arc-shaped; the inlay 4 is cross-shaped or straight or eleven-shaped; the inlay slot 3-1 is a through hole on the die body 3; the die body 3 is made of a material with good toughness production, the inlay 4 is made of wear-resistant materials.

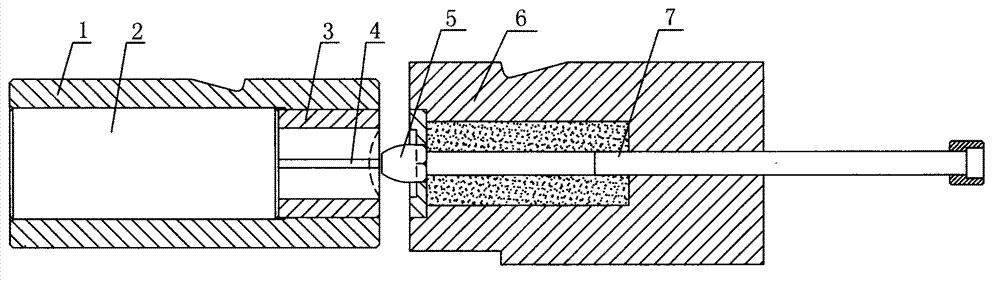

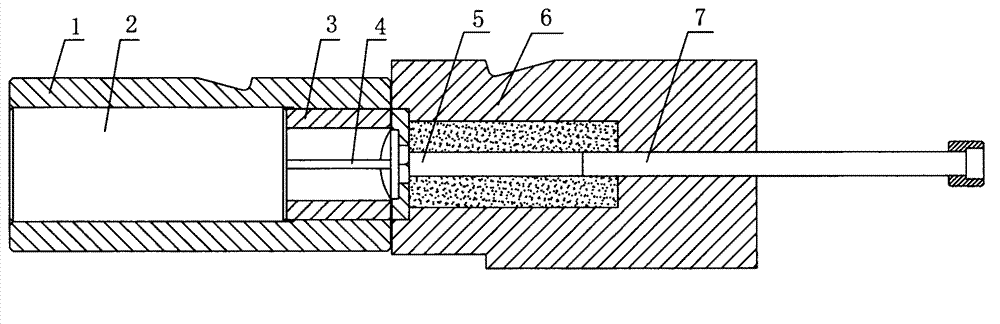

[0018] Such as figure 2 , image 3 with Figure 4 The shown die structure and the main die structure carry out mold closing movement, push the product 5 into the thimble hole, the head of the product 5 is formed in the forming groove 3-2 on the die body 3, and is pressed into an obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com