Arbitrary-radian outer circle grinding process equipment

A process equipment, cylindrical grinding technology, used in grinding/polishing equipment, metal processing equipment, grinding machine parts, etc. Requirements and other issues, to avoid the constraint of the maximum rotation diameter, improve work efficiency and quality, and achieve the effect of large workpiece rotation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

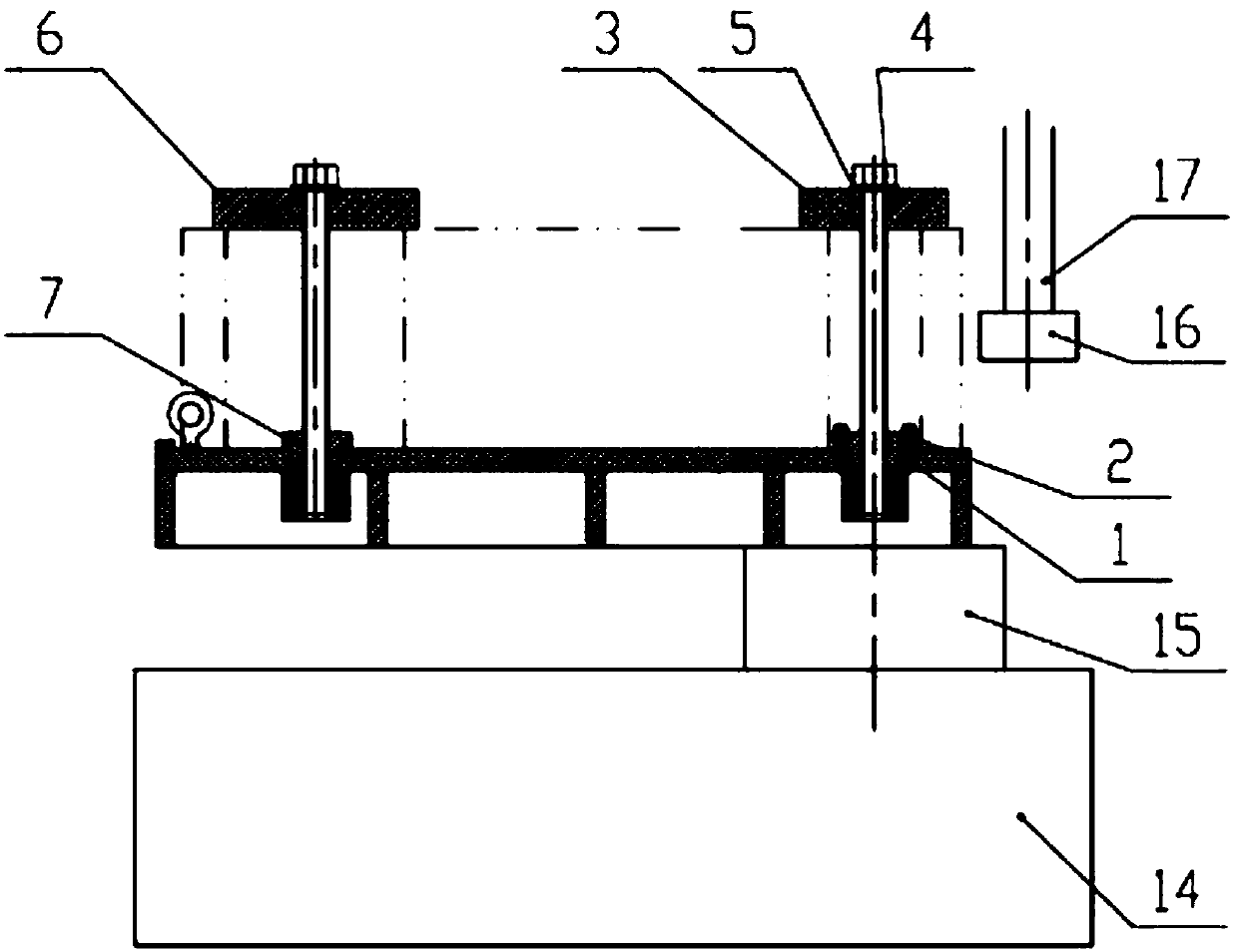

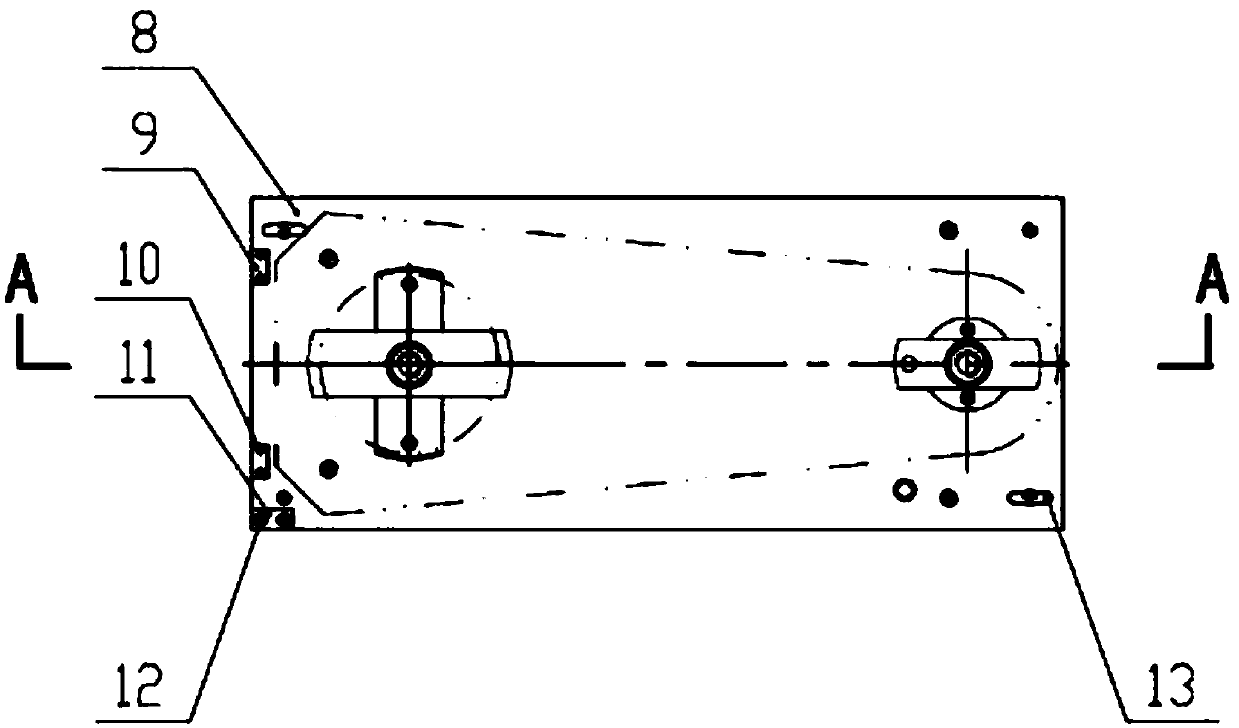

[0010] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0011] In the present invention, the workpiece is first fixed by the positioning pin 2, the small pressing plate 3, the hexagon head bolt 4, the standard type spring washer, 5 and the large pressing plate 6. During processing, the grinding wheel shaft 17 is first started to drive the grinding wheel 16 to rotate. The turntable 14 drives the workpiece to perform reciprocating rotary motion, and the arc of rotation is equal to the arc of the processed outer circle. The grinding wheel shaft 17 of the main shaft of the machine tool drives the grinding wheel 16 to rotate as the main cutting motion, and together with the reciprocating rotary motion of the CNC turntable 14, the grinding process of the incomplete arc excircle is realized.

[0012] To sum up, the present invention is easy to use, stable and reliable, and has high working efficiency, which not only reduces the labor int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com