Steel ball sealing cone surface processing method

A sealing cone surface and processing method technology, which is applied in the field of sealing surface processing, can solve problems such as sealing reliability discount, untimely sealing, and sealing failure, and achieve the effects of cost saving, simple operation, and guaranteed size and roughness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

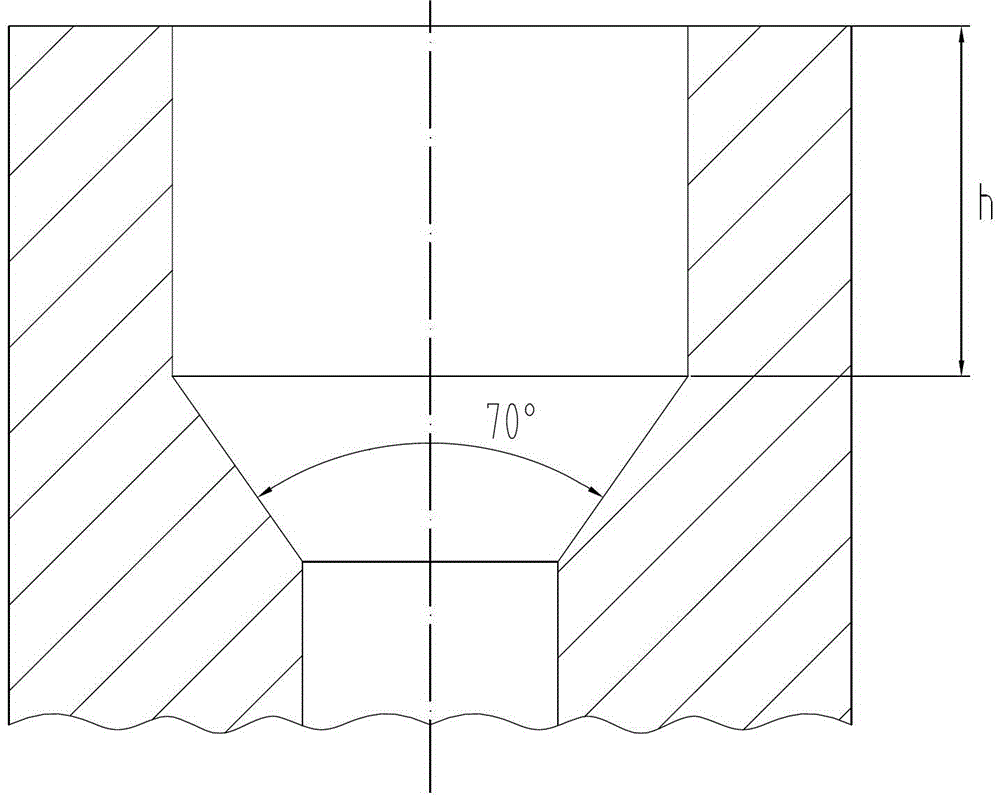

[0014] Such as figure 1 As shown, the method of processing the steel ball sealing cone surface first uses a center drill or a profile drill with a cone angle of 70° to process a hole with a depth h according to the depth required by the design, that is, a 70° conical surface is also processed at the same time. .

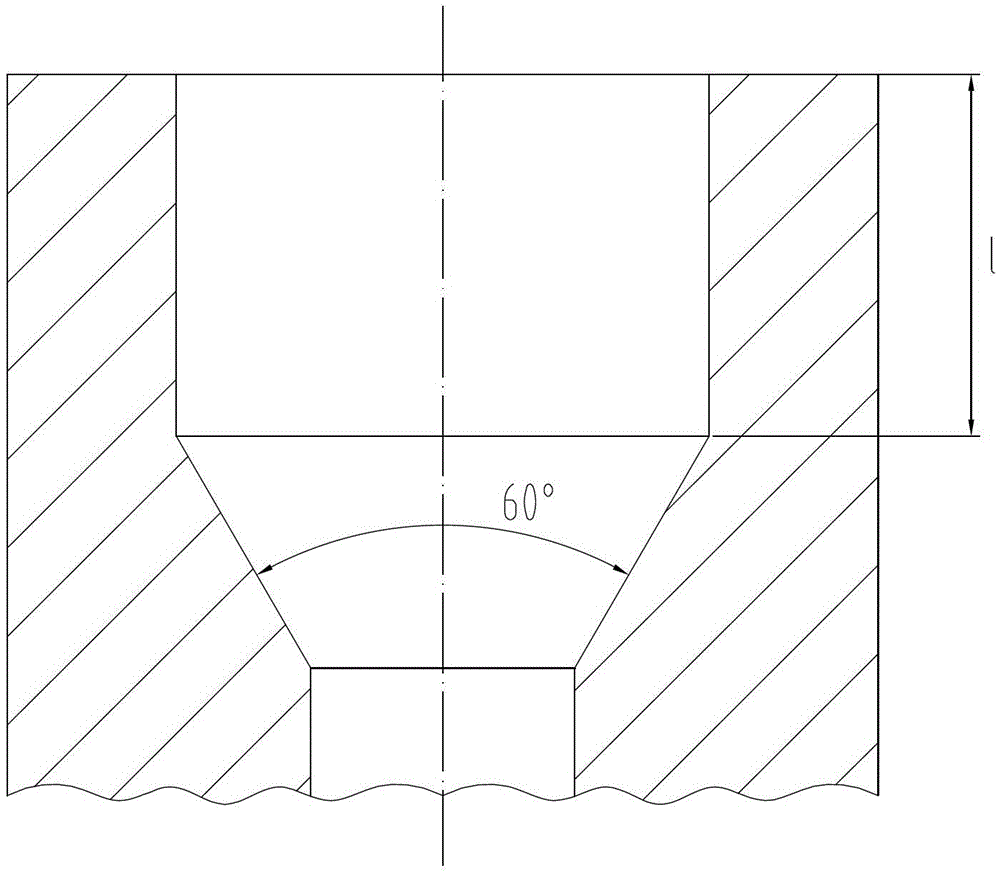

[0015] Such as figure 2 As shown, the steel ball sealing cone surface processing method is to use a center drill or a form drill with a cone angle of 60° to process the cone surface with an angle of 60° required by the design, and at the same time process a hole with a depth of l. In the second processing, firstly, the coaxiality of the two-processed drill bit is guaranteed by a vertical machine tool with an accuracy of not less than ±0.01, so that the holes processed twice are coaxial, and secondly, the depth of the two-processed holes is guaranteed to be equal, that is h=l.

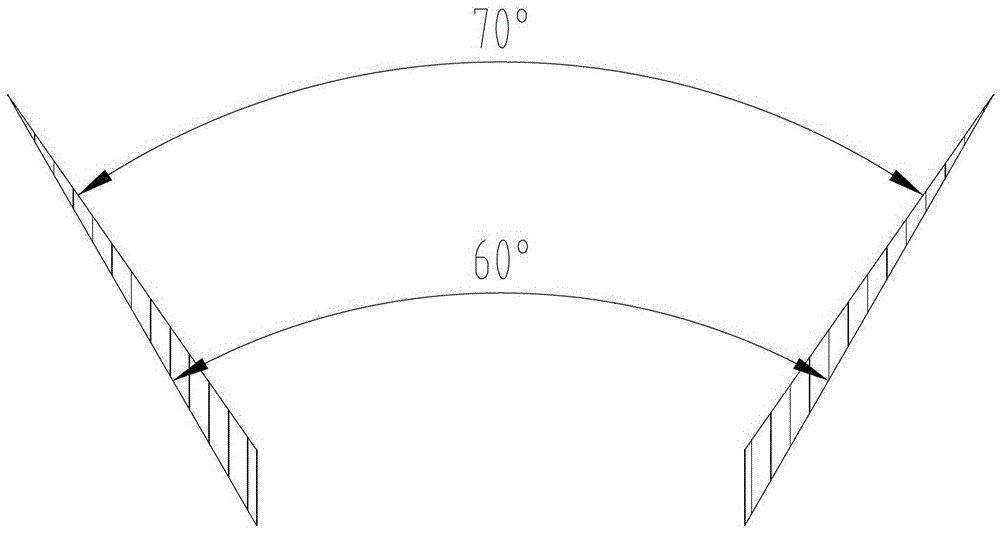

[0016] Such as image 3 As shown, the machining method of the steel ball sealing cone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com