Rivet-free riveting technology for socket conducting plates and socket structure thereof

A technology of rivetless riveting and conductive sheet, which is applied in the direction of riveted connection and contact parts, can solve the problems of prolonging processing time, reducing processing efficiency, and increasing factory cost, so as to improve processing efficiency, save processing time, and reduce process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] A rivetless riveting process for socket conductive sheets. First, the split conductive sheet is formed by machining, and then the split conductive sheet is stamped and fixed together by rivetless riveting technology. At the same time, the insert spring is connected to the conductive sheet by rivetless riveting technology. Stamping is held together.

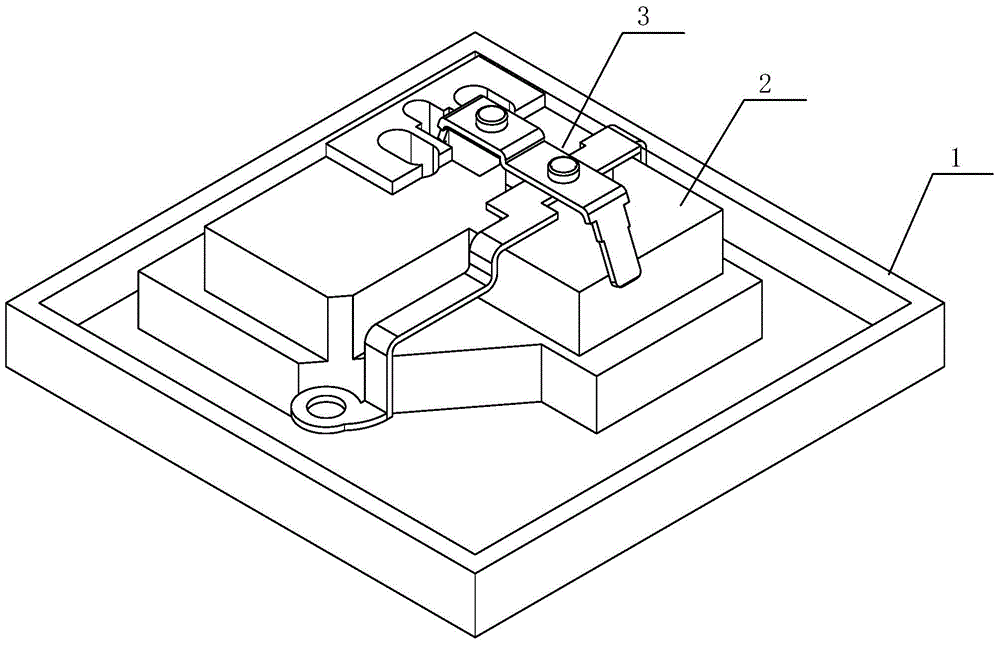

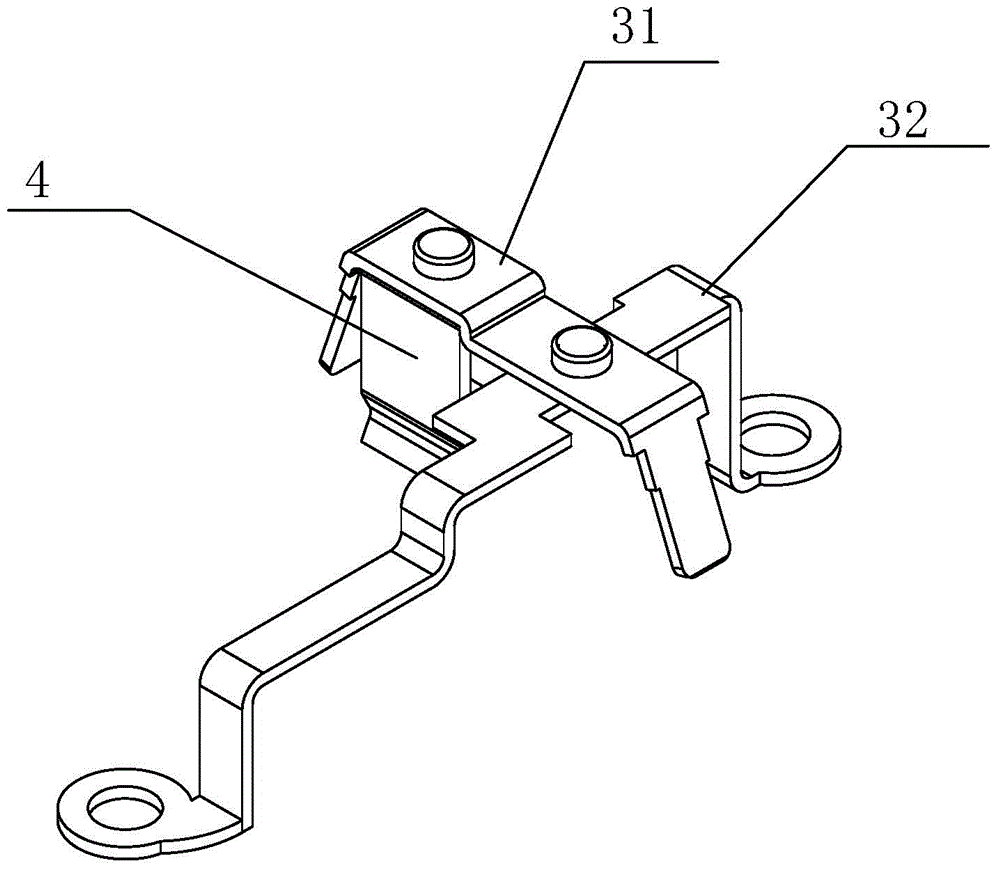

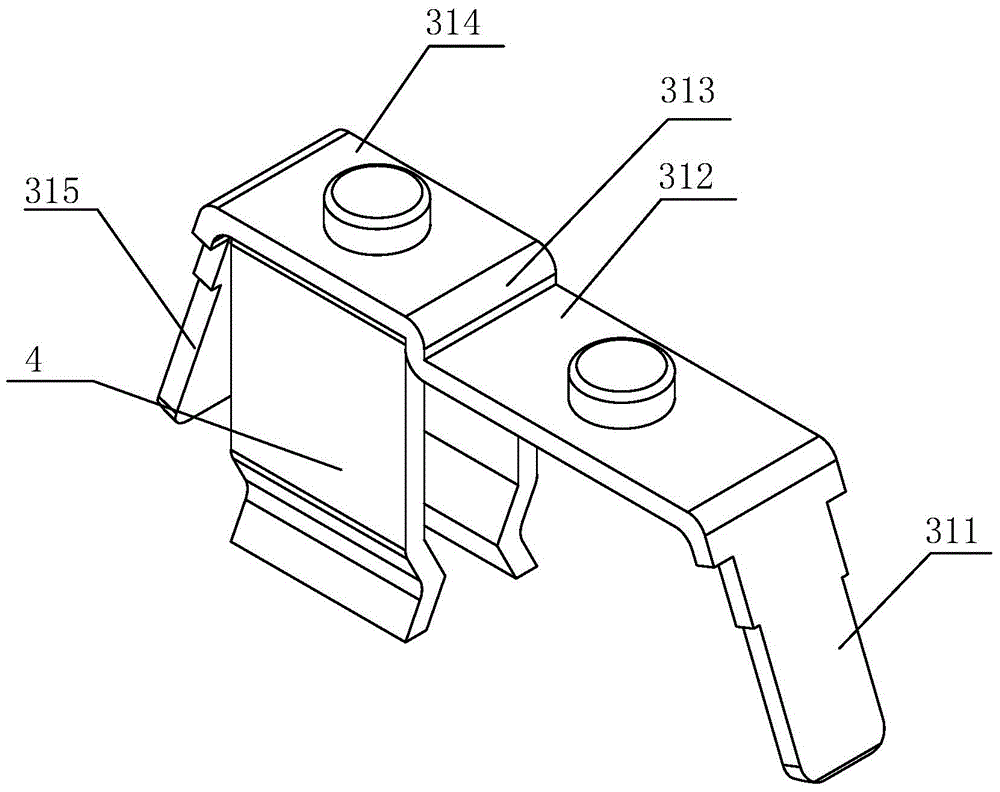

[0018] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown is a socket structure that adopts a rivetless riveting technology conductive sheet, including an outer shell 1, a bracket 2 is arranged in the outer shell 1, and a live wire interface, a neutral wire interface and a live wire interface are arranged in the described bracket 2 The ground wire interface, the ground wire interface is provided with a conductive sheet 3, the conductive sheet 3 includes at least one first conductive sheet 31 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com