Anti-scrabbling door vane structure for elevator

A door knife and anti-pickling technology, which is applied to elevators, transportation and packaging in buildings, can solve the problems of long installation and commissioning cycle, increased failure rate of door operators, complex structure of door operators, etc., to improve debugging and installation Efficiency, simplification of structure, and effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

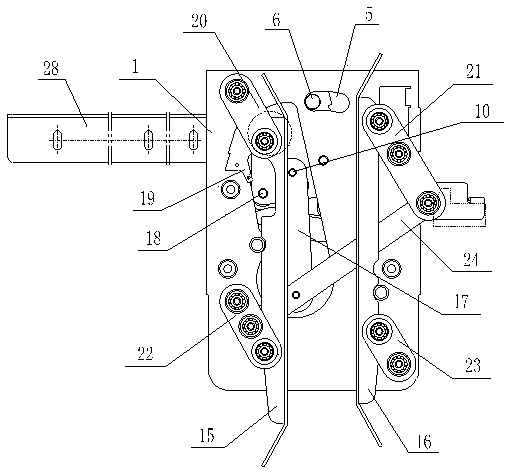

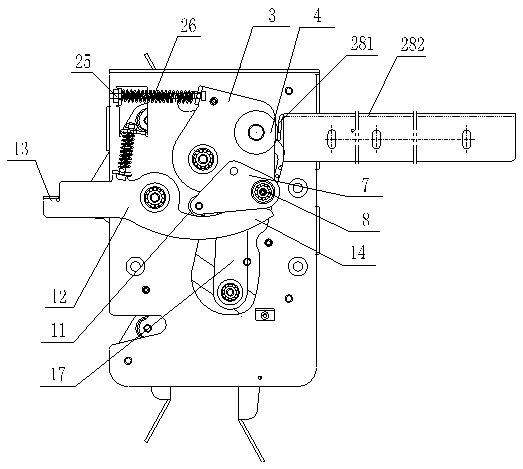

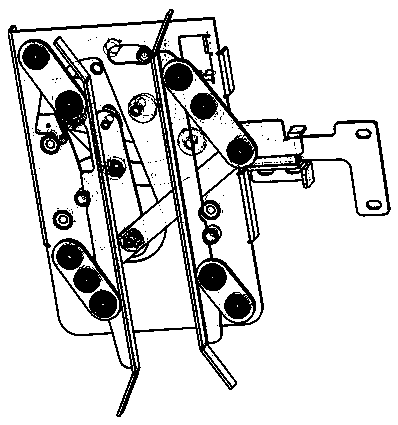

[0024] like figure 1 , figure 2 and image 3 Shown a kind of anti-scrambling door knife structure for elevator, comprises the door knife base plate 1 that is installed on the door machine (as Figure 7 As shown), a relief hole 2 is provided on the door knife bottom plate 1, and a knife lifting plate 3 is provided on the back of the door knife bottom plate 1, and the knife lifting plate 3 is rotationally connected with the door knife bottom plate 1, A rotating ball 4 is provided on the knife lifting plate 3, and the rotating ball 4 cooperates with the guide rail 28 provided on the door operator. The guide rail 28 includes an inclined section 281 at the front and a horizontal section 282 at the rear. A first guide waist hole 5 is set on the door knife bottom plate 1, a first guide shaft 6 is set on the upper part of the knife lifting plate 3, and the first guide sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com