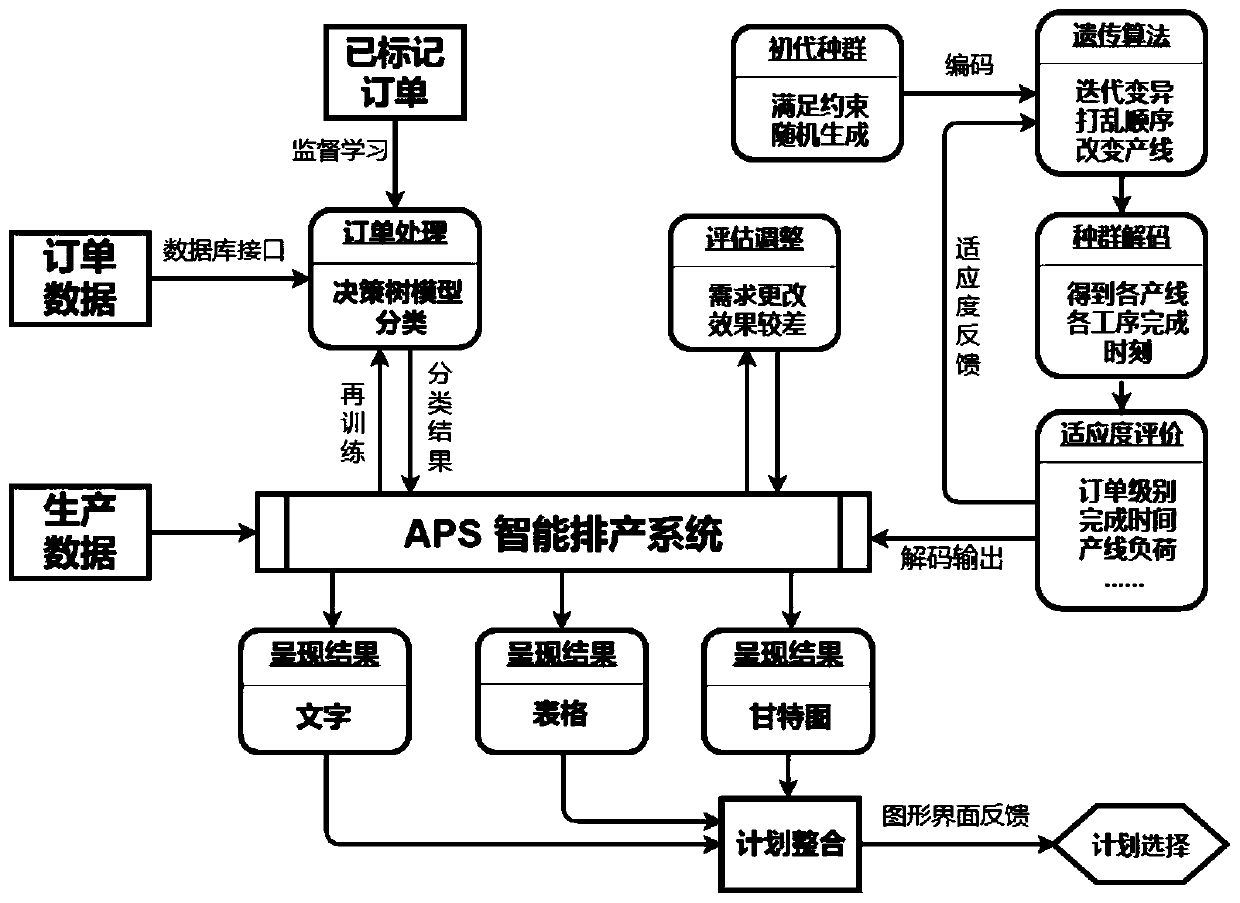

Workshop production scheduling method and system based on genetic algorithm

A genetic algorithm and workshop technology, applied in the field of workshop production scheduling management, can solve the problems of relying on manual production scheduling, lack of consideration of the overall balance of the production line, and single target.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

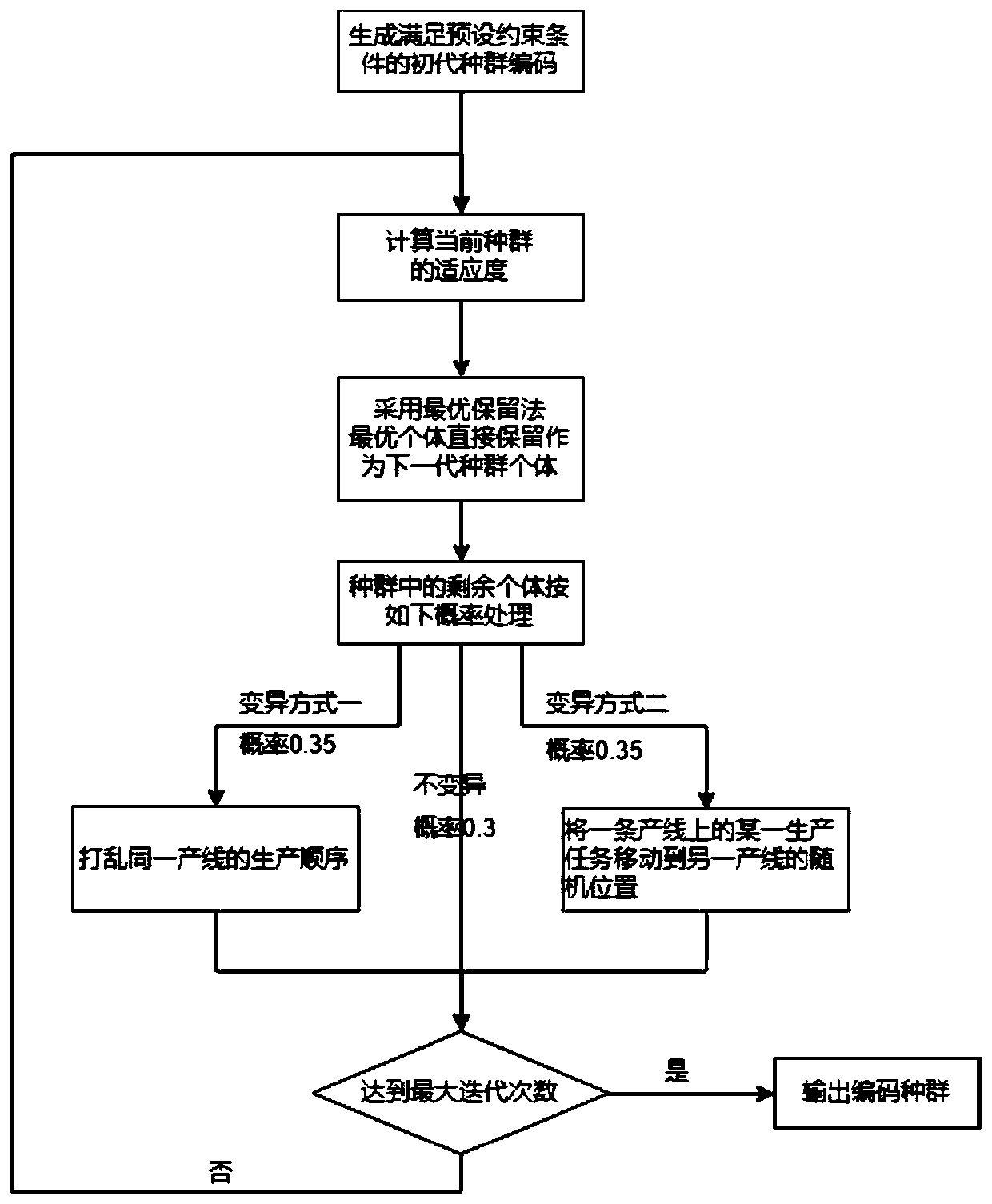

[0128] to combine figure 2 As shown, Embodiment 1 is the main steps of the genetic algorithm-based scheme generation module, and Embodiment 2 to Example 4 are used as supplementary descriptions of Embodiment 1, specifically including:

[0129] enter:

[0130] 1. The maximum iteration number N of genetic algorithm operation;

[0131] 2. The serial number and quantity of the products to be produced contained in each order to be produced, the process that needs to be completed to produce each product, and the priority of each order to be produced (output by the order processing module);

[0132] 3. The time required for each process in each production line;

[0133] 4. Time required for line change t ex .

[0134] Output: The final population coding scheme after the iteration of the genetic algorithm is completed.

[0135] The specific implementation steps of the scheme generation based on genetic algorithm include:

[0136] S21. In the case of satisfying the constraint co...

specific example

[0171] First arrange all the unit tasks that need to be completed: the unit tasks are arranged in ascending order of the serial numbers of the corresponding products; when the product serial numbers are the same, they are arranged in ascending order of the process sequence of the products. Note that the total number of unit tasks is J.

[0172] Then use a two-row matrix to represent the production scheduling plan, the dth column corresponds to the dth unit task, the value of the first row is the number of the production line that completed the unit task, and the value of the second row is the number of the unit task on the production line on the production sequence. The matrix is in one-to-one correspondence with the production scheduling plan, that is, it can be seen from the matrix what the production scheduling plan is.

[0173] The following example illustrates the encoding scheme:

[0174] The required products and their production processes are shown in Table 3 below...

Embodiment 3

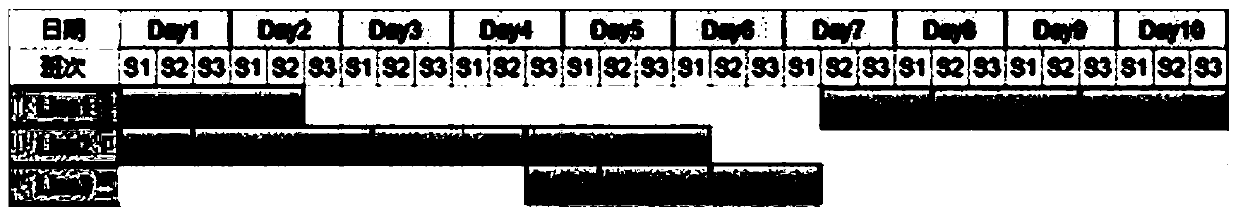

[0185] Here, for the decoding of the encoding scheme (that is, the encoding matrix E) involved in step S22 in the first embodiment, a matrix F including the production process sequence and its completion time on the production line is obtained. Now combined with specific examples to illustrate.

[0186] Combined with the required production products and their production process tables, the production process sequences of each production line are obtained. According to the obtained sequence of procedures, solve each minimum value. The result of the solution is represented by a matrix F that includes the sequence of processes produced on the production line and its completion time. Each element in the matrix records the completion time. If the production line does not work after k processes, then the values of the elements behind the row It is the moment when the last process is completed.

[0187] Decoding the encoding matrix E to obtain the matrix F, the conversion proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com