Ball separating and riveting method for assembling small-sized deep groove ball bearing

A deep groove ball bearing and riveting technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of poor bearing flexibility, easy deformation of cages, and many safety hazards, and achieve reliable and appropriate riveting. The riveting head is uniform and not biased, and the effect of reducing the site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

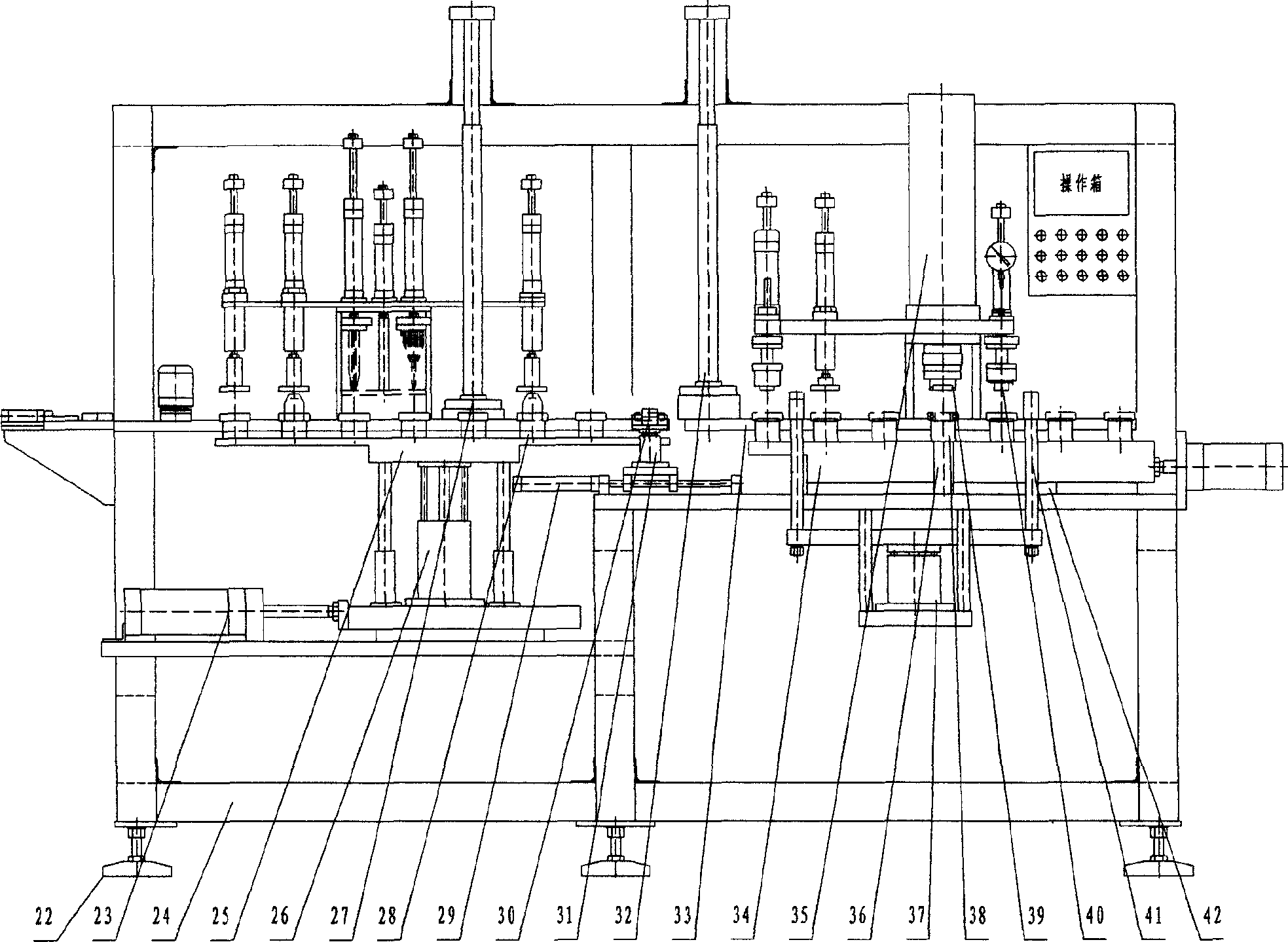

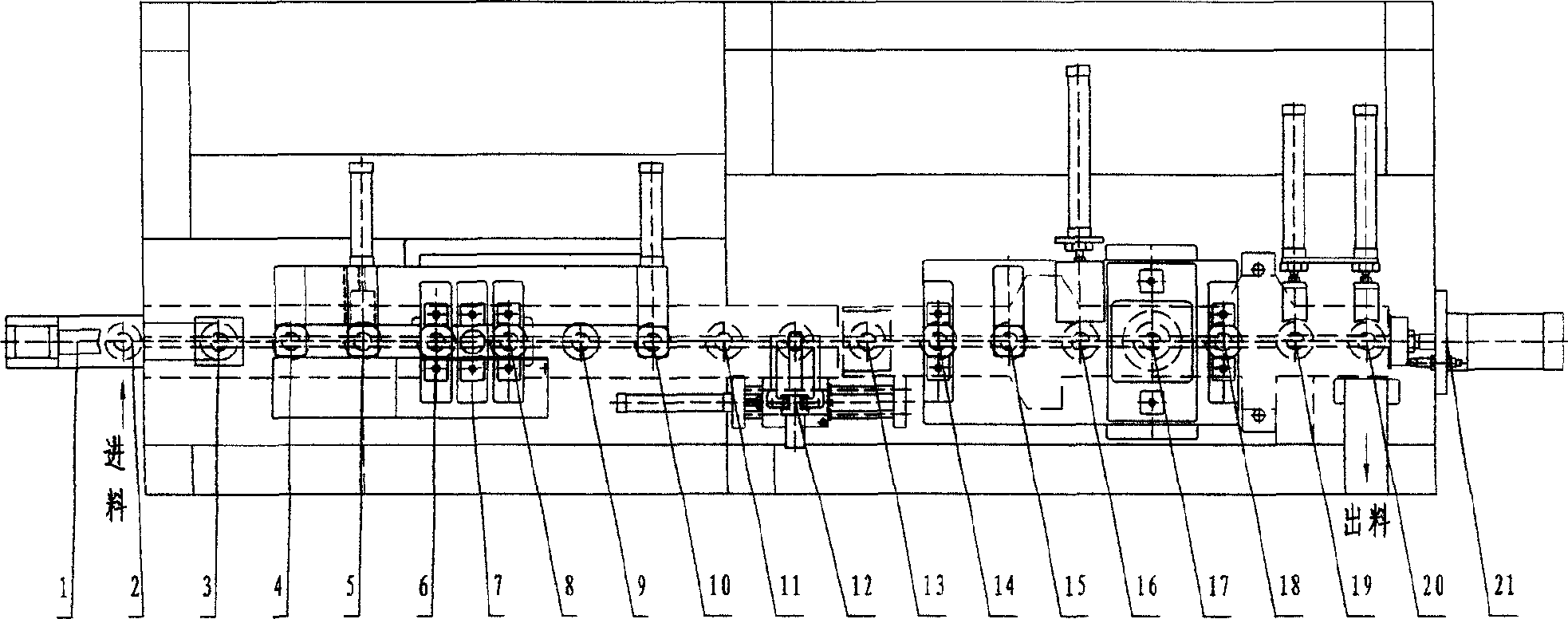

[0064] According to the accompanying drawings, a split ball riveting machine is manufactured, and a two-layer rectangular frame is made of aluminum alloy profiles. On the middle plate, the following devices are positioned with conical pins from left to right and fastened with screws:

[0065] On the left is the ball distribution part, which is installed in sequence from left to right: feeding cylinder, ball position positioning device, ball position detection device, ball dialing device, ball number inspection device, NG rejecting device, ball distribution device, outer garden positioning device, uniform Ball device, nail-free cage device, inspection nail-free cage and NG removal device;

[0066] The right side is the riveting part, which is installed in order from left to right: placing nailed cage device, cage clapping device, checking nailed cage device, NG rejecting device, pressurized riveting device, riveting inspection device, NG rejecting device and unloading device; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com