Assembly method and connection mode of roof, parts and plates of automobile

A technology of automobile roof and assembly method, which is applied in the directions of motor vehicles, transportation and packaging, can solve the problems of wasting site area, many assembly processes, occupying space, etc., and achieves the effect of saving site area, reducing cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

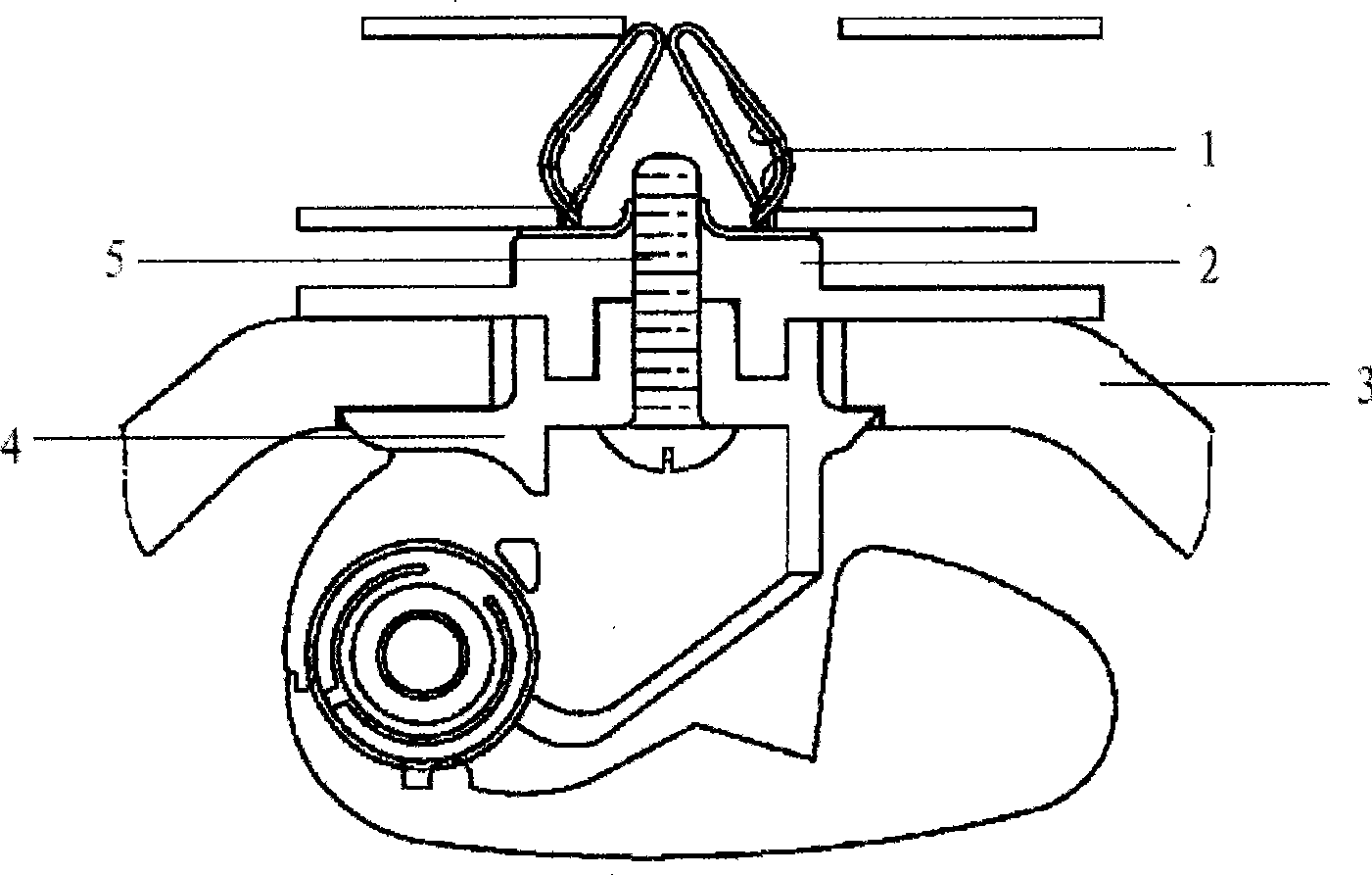

[0018] The accessories that need to be installed on the ceiling are sun visors, passenger handrails, glasses cases or dome lights, and the installation principles are the same. In this embodiment, the installation of the passenger handrails is taken as an example.

[0019] As shown in the figure, corresponding to the position of the installation hole of the ceiling body, place the passenger armrest fixing seat 4 under the ceiling 3, place the passenger armrest mounting bracket 2 on the ceiling, and place the buckle 1 used to connect the body sheet metal on the accessories installation On the bracket, the accessory fixing seat 4, the ceiling 3, the accessory mounting bracket 2, and the buckle 1 are connected and fixed by screws 5. The wiring harness can also be fixed on the ceiling with glue first, and the wiring harness can pass through the ceiling body mounting hole and be exposed from the gap of the accessory mounting bracket (ceiling light mounting bracket).

[0020] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com