Bridge prefabricating device adopting self-propelled line production and method thereof

A flow-operated, self-propelled technology, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of difficult construction quality assurance, low efficiency of prefabricated site use, and impact on beam production efficiency, etc., to achieve good promotion The effect of application value and economic and social benefits, improving beam manufacturing efficiency and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

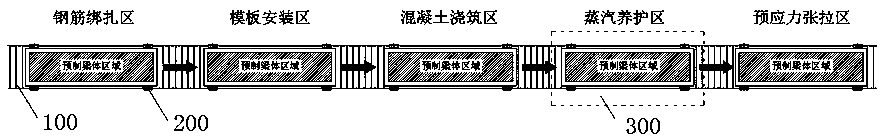

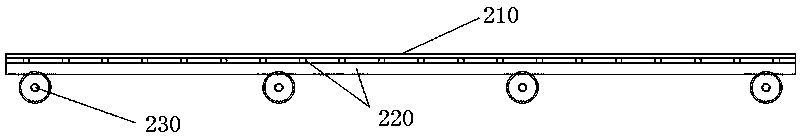

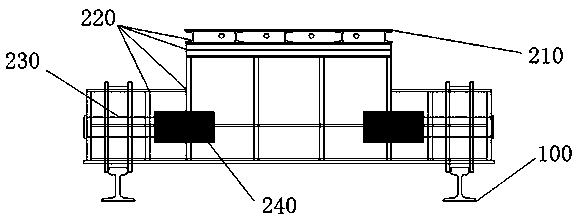

[0014] Such as Figure 1~3 As shown, a bridge prefabrication device adopting self-propelled assembly line operation includes a steel rail 100 at the bottom, a trolley 200 that can move along the rail is arranged on the rail, and steel bar binding is arranged sequentially along the length direction of the rail from front to back Area, formwork installation area, concrete pouring area, steam curing area and prestress tension area, steam curing shed 300 is set on the rails in the steam curing area.

[0015] The invention realizes the fixed construction process of the bridge prefabrication process, and the operation mode of completing each process task in different areas, thereby realizing that the beam body can complete various construction processes (binding steel bars, formwork, pouring concrete, curing) in different areas on the same trolley , Tensile prestress) prefabrication work can improve the efficiency of tooling equipment, shorten the construction period, save site area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com