Mechanism for burying waste residue in reservoir bottom

A waste residue and reservoir technology, applied in large-capacity bulk material storage, water conservancy projects, marine engineering and other directions to achieve the effect of saving project investment, reducing a large number of occupations, and reducing site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the present invention, a large amount of waste soil and rock produced during the construction of the power station is called reservoir bottom slag 1, and the humus soil layer on the surface is removed, rolled and buried in layers in the dead storage capacity of the reservoir in an idle state.

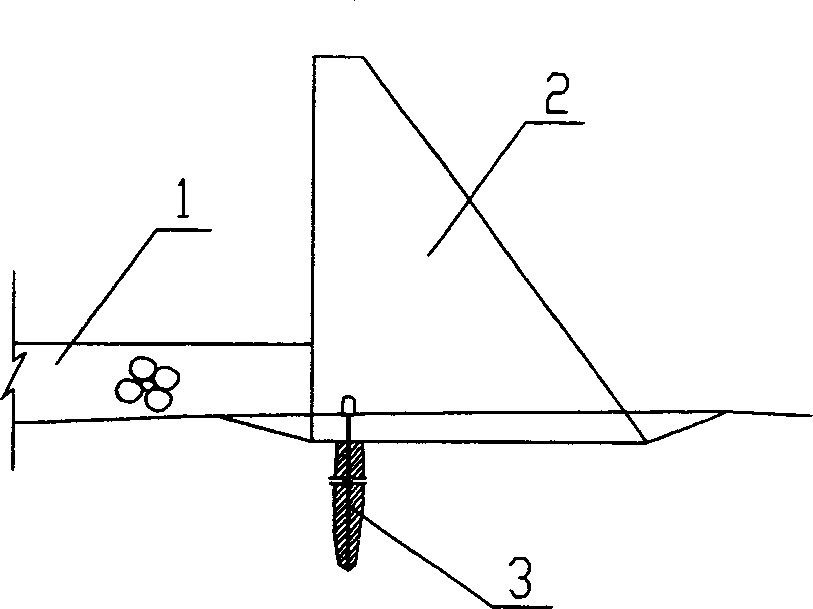

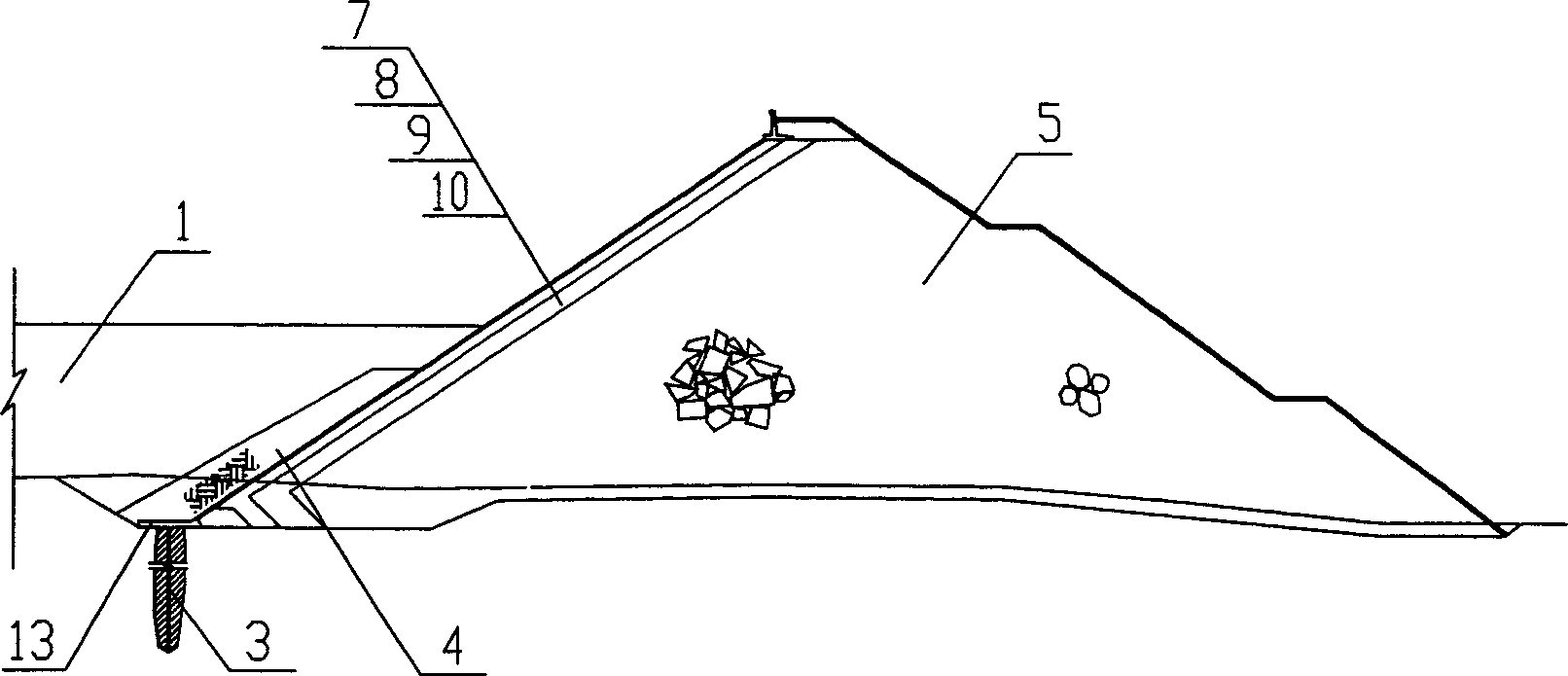

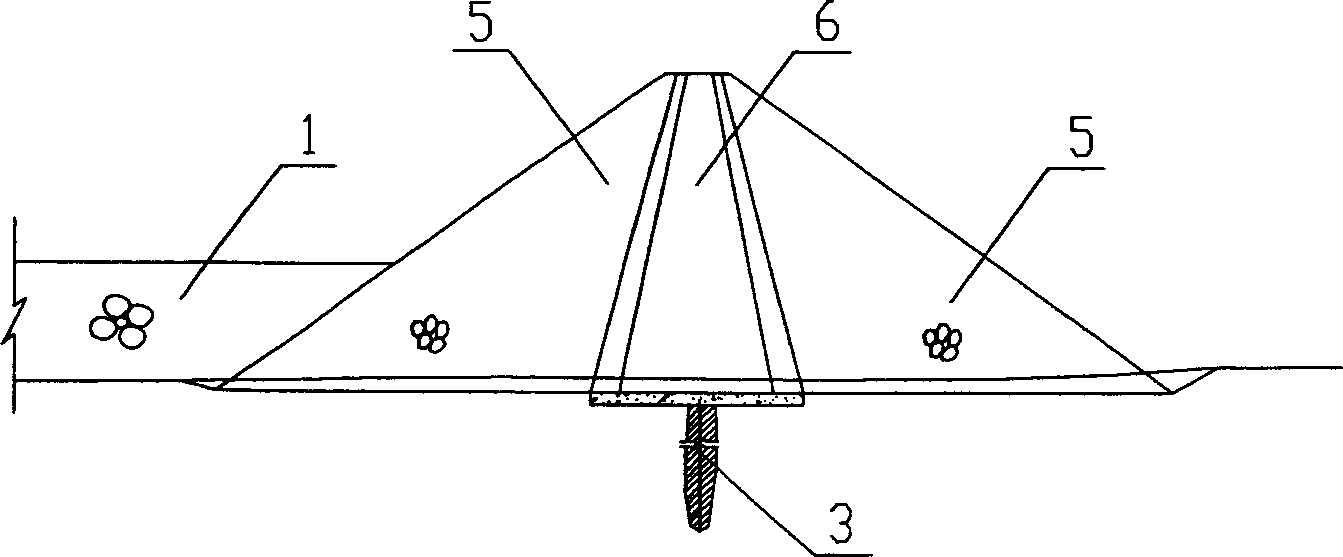

[0024] figure 1 , figure 2 , image 3 What is shown is the implementation plan in which the water is only blocked by the dam, and the surface layer anti-seepage facilities (protective layer) are not provided on the bank and the bottom of the reservoir. figure 1 represents the concrete gravity dam 2, figure 2 is a concrete face dam, image 3 It is a rockfill dam with a clay core wall 6 . In this scheme, the surface of the slag filling 1 at the bottom of the reservoir is horizontal, and the water inlet and outlet 14 near the forebay 15 are slope-like, and the slag slope angle is smaller than the underwater repose angle of the slag filling, which is the maximum angle to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com