Method for improving pre-splitting crack-forming effect by pre-grouting and reinforcing surrounding rock of side slope

A technology of grouting reinforcement and pre-grouting, which is applied in excavation, soil protection, climate change adaptation, etc., can solve the problems of increased risk factors and high cost, and achieve simple process, less material consumption and fast construction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

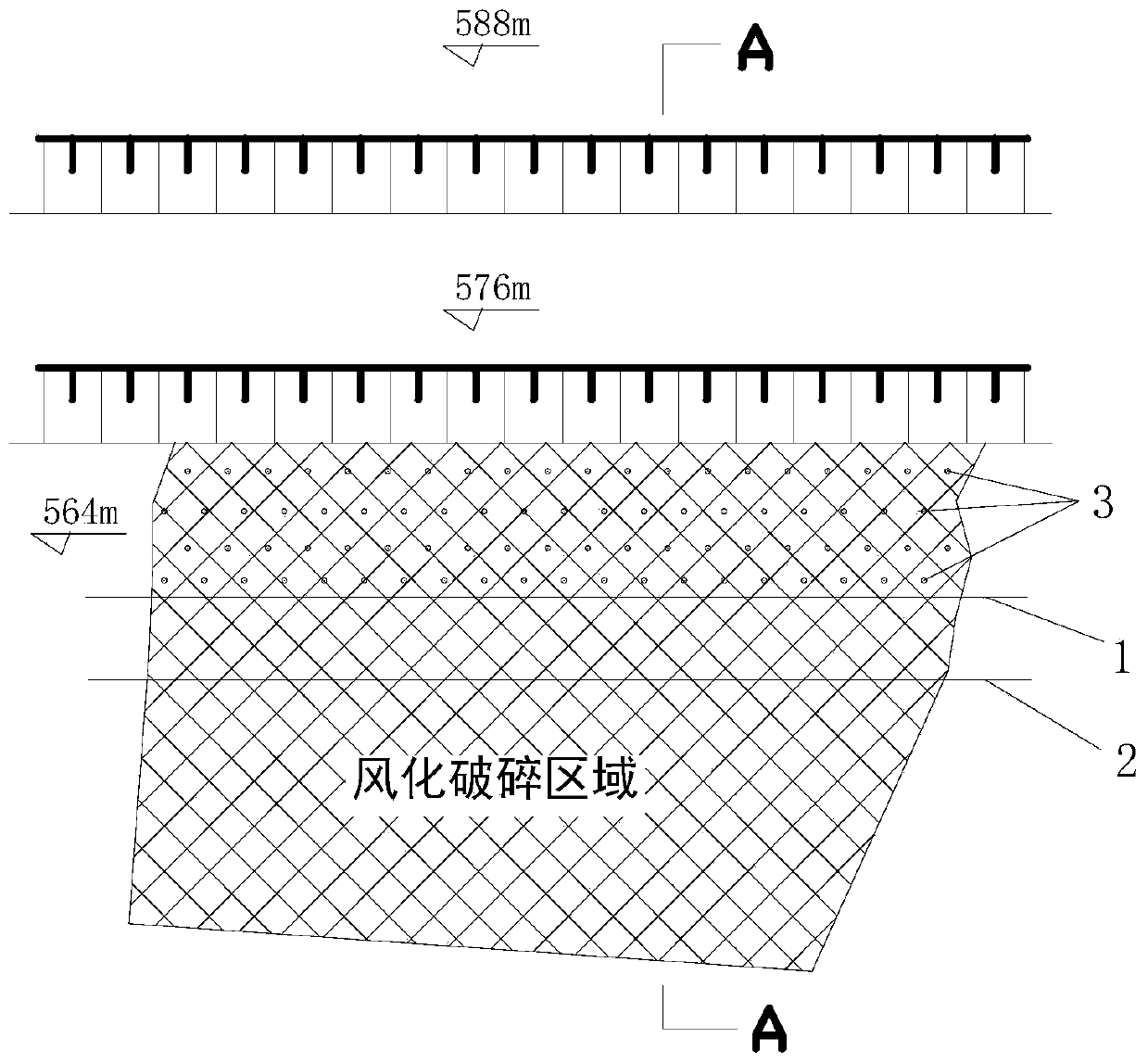

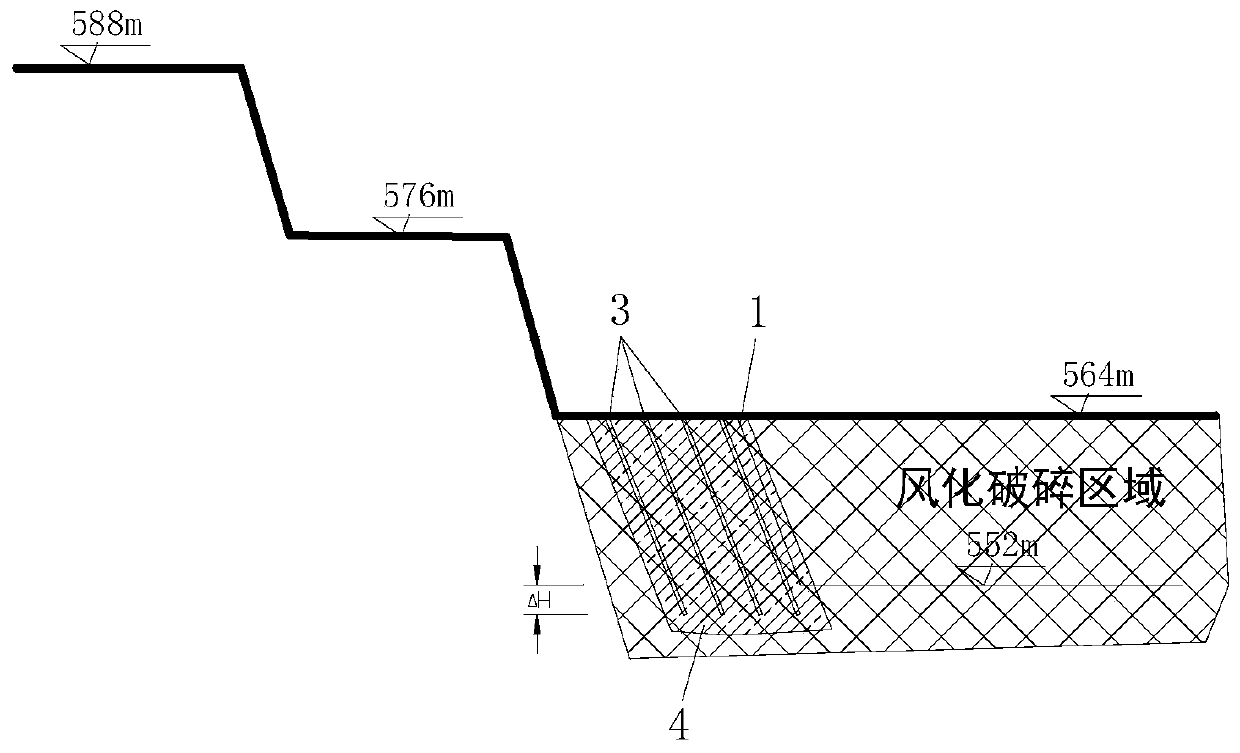

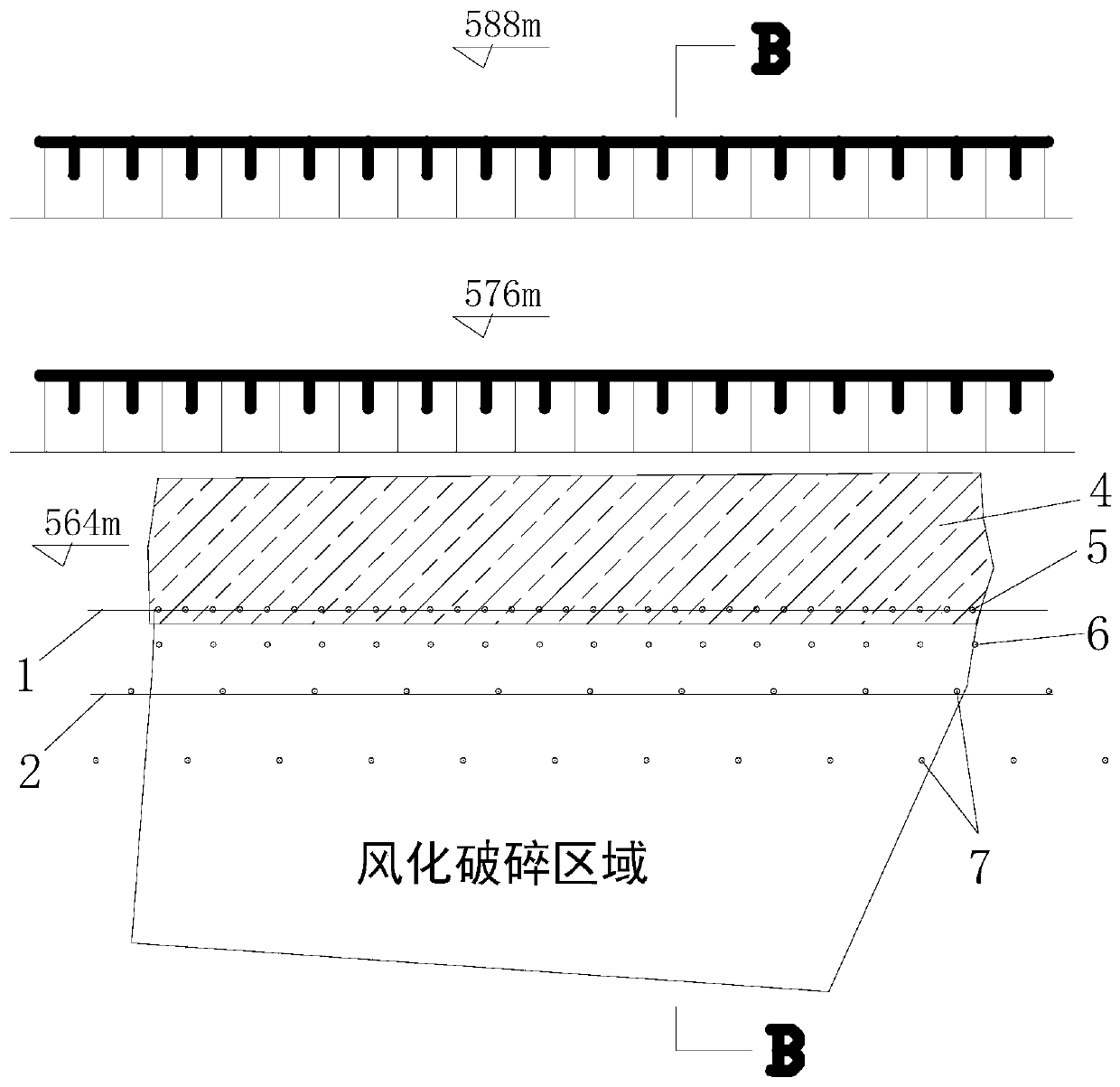

[0041] Embodiment one, such as Figure 1~4 As shown, a method of pre-grouting to strengthen the surrounding rock of the slope to improve the effect of pre-cracking and cracking is carried out according to the following steps:

[0042] S1: Determine the weathered and broken area of the slope near the end, stake out the end slope, delineate the scope of grouting reinforcement, and design the design slope top line 1 and design slope bottom line 2;

[0043] S2: Through the indoor grouting test, the feasibility of gel material grouting reinforcement for broken rock mass is tested and analyzed, and the effect of grouting amount, grout ratio scheme, accelerator and age on the broken rock mass reinforcement is obtained; cement is used Slurry is used as a gel material. The water-cement ratio of the cement slurry is 1:1, and its diffusion radius is 2-6 meters. Then, the grouting holes are drilled and staked out in the grouting reinforcement area. layout;

[0044] S3: Grouting hole d...

Embodiment 2

[0065] Embodiment 2, a method for pre-grouting and strengthening the surrounding rock of the slope to improve the effect of pre-cracking and cracking, is carried out according to the following steps:

[0066] S1: Determine the weathered and broken area of the slope near the end, stake out the end slope, and delineate the scope of grouting reinforcement;

[0067] S2: Drill and stake out the grouting hole in the grouting reinforcement area;

[0068] S3: Grouting hole drilling;

[0069] S4: cleaning the grouting hole;

[0070] S5: performing pressure grouting on the grouting hole;

[0071] S6: Confirm that the grouting pressure and grouting amount in the grouting hole meet the requirements;

[0072] S7: After confirming that the grout in the grouting hole has reached gel time and sufficient strength, implement vibration-reducing controlled blasting to protect the slope;

[0073] S8: Arrange pre-split holes along the contour of the designed slope in the blasting area, arrang...

Embodiment 3

[0086] Embodiment 3, a method for pre-grouting and strengthening the surrounding rock of the slope to improve the effect of pre-cracking and cracking, is carried out according to the following steps:

[0087] S1: Determine the weathered and broken area of the slope near the end, stake out the end slope, and delineate the scope of grouting reinforcement;

[0088] S2: Drill and stake out the grouting hole in the grouting reinforcement area;

[0089] S3: Grouting hole drilling;

[0090] S4: cleaning the grouting hole;

[0091] S5: performing pressure grouting on the grouting hole;

[0092] S6: Confirm that the grouting pressure and grouting amount in the grouting hole meet the requirements;

[0093] S7: After confirming that the grout in the grouting hole has reached gel time and sufficient strength, implement vibration-reducing controlled blasting to protect the slope;

[0094] S8: Arrange pre-split holes along the contour of the designed slope in the blasting area, arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com