Clamp body die of spring grounding clamp

A grounding card and card body technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high production cost, low production efficiency, increase of semi-finished product transportation and warehouse occupation, and reduce transportation and warehouse occupation. The effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

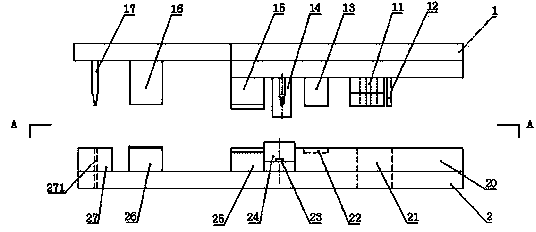

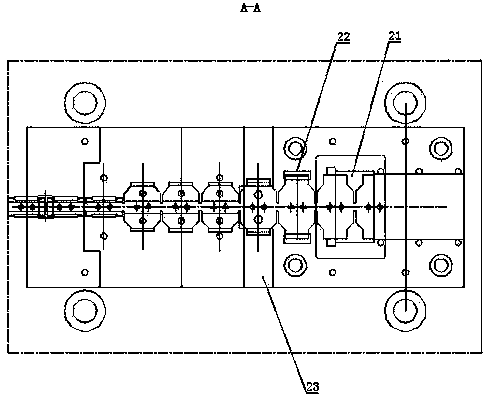

[0028] see figure 1 , 2 , the present invention discloses a spring grounding card body mold, the card body mold adopts copper strips to make the card body, the mold includes an upper template 1, a lower template 2, and a guide post arranged between the upper template 1 and the lower template 2 Guide sleeve structure.

[0029] Between the upper template 1 and the lower template 2, the punching and trimming station, the trimming station, the pre-circling station, the rounding station, the pre-forming punching station, and the first empty station are arranged in sequence along the horizontal direction. Step station, second empty step station, forming station, third empty step station, cutting station. specific:

[0030] Punching and edge trimming station, trimming punch 11 and short axis hole punch 12 are installed on the upper template 1 of the trimming station; punching and trimming station, lower template 2 of the edge trimming station are installed to cooperate The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com