Aluminum cellular composite board manufacture method

A manufacturing method and technology of aluminum honeycomb, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of bending deformation of aluminum honeycomb panels, large film stress, deformation of aluminum honeycomb panels, etc. Corrosion resistance, thermal expansion and contraction, tight adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

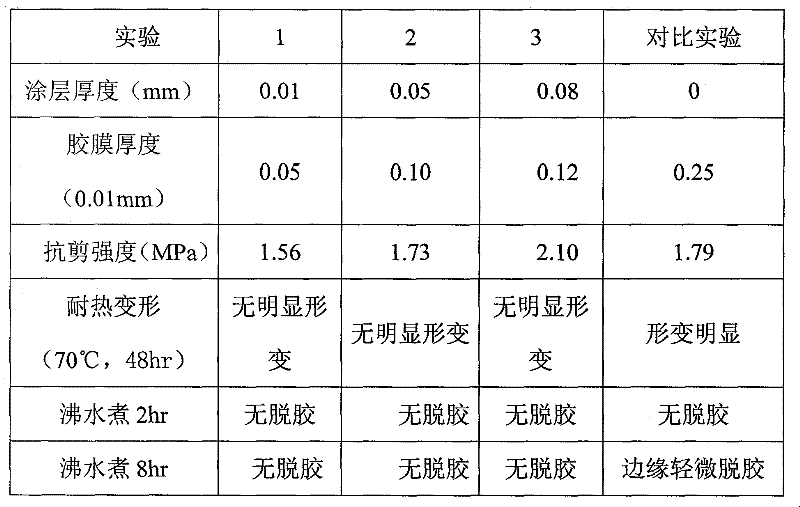

[0019] Use 1.0mm thick aluminum alloy coated with oil-modified polyvinylidene fluoride as the panel, and use 5-25mm thick aluminum honeycomb as the core material. Firstly, the honeycomb core is treated with thermoplastic powder and then leveled, and then hot melt Adhesive film is used to bond the surface material and the core material, and the aluminum honeycomb panel is obtained by hot pressing at 150°C for 10 minutes, and cooling after compounding. The experimental results are shown in the table below.

[0020] Comparative Experiment:

[0021] Use 1.0mm thick aluminum alloy coated with oil-modified polyvinylidene fluoride as the panel, use 5-25mm thick aluminum honeycomb as the core material, and directly use hot-melt adhesive film to realize the bonding of the surface material and the core material. Hot pressing and compounding at 150°C for 10 minutes, after compounding and cooling, the aluminum honeycomb panel was obtained. The experimental results are shown in the table b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com