A Steam Oxidation Pit Furnace

An oxidation well and steam technology, applied in vertical furnaces, furnaces, furnace types, etc., can solve the problems that the heating temperature cannot be accurately controlled, cannot meet the needs of social and development, and the welding points of pipelines are easy to fall off, so as to reduce thermal expansion and cooling. shrinking phenomenon, good density, and the effect of increasing steam purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

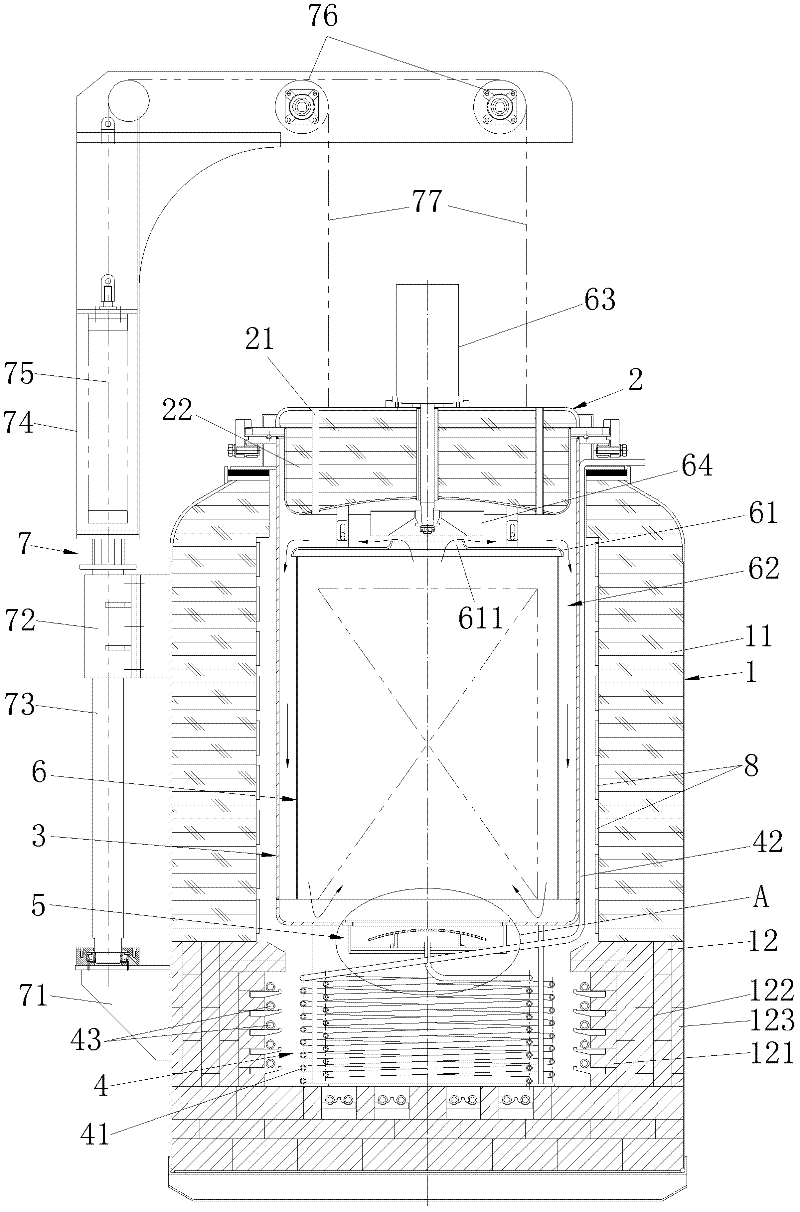

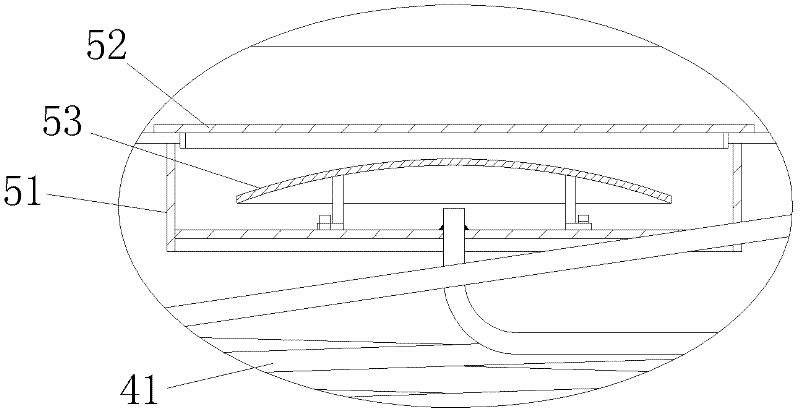

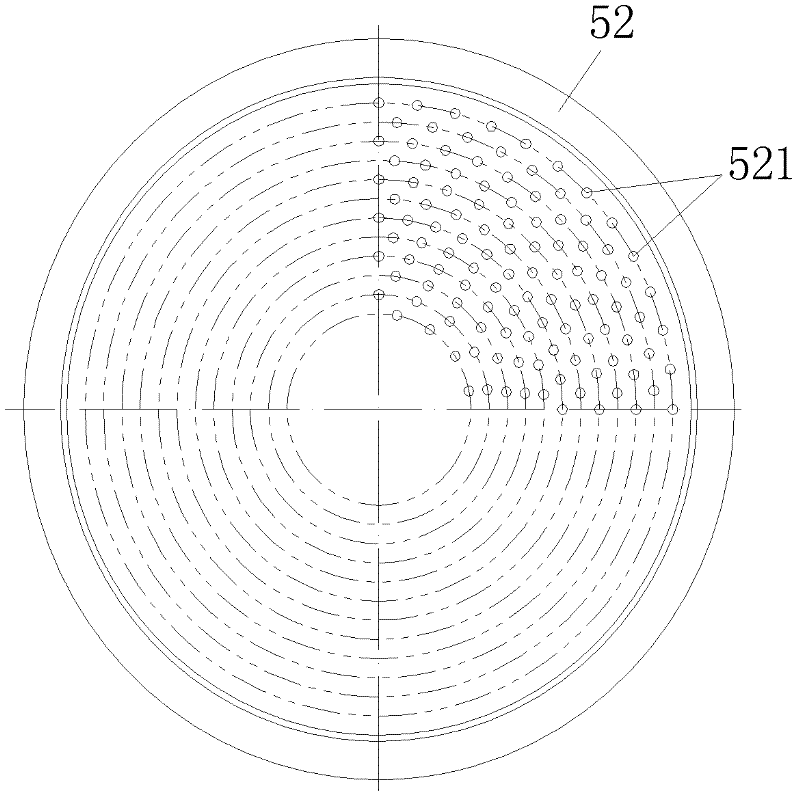

[0024] Reference figure 1 , The present invention is a steam oxidation pit furnace, comprising a furnace shell 1, a furnace cover 2, a furnace pot 3 placed in the furnace shell 1, and a heating mechanism for heating the workpiece in the furnace shell 1. The bottom of the furnace shell 1 A steam preheating mechanism 4 connected to an external steam source is provided, and the steam preheating mechanism 4 is communicated with the bottom of the furnace pot 3 through a steam releasing structure 5.

[0025] The wall of the furnace shell 1 corresponding to the furnace pot 3 is provided with a first insulation layer 11 composed of aluminum silicate insulation cotton, and the wall corresponding to the steam preheating mechanism 4 is provided with a second insulation layer 12 composed of insulation bricks ; The second insulation layer 12 is a three-layer structure, the inner layer 121 is a high bauxite material insulation shelf brick layer, the outer layer 123 is a lightweight refractory c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com