Two-speed transmission for new energy vehicles

A technology for new energy vehicles and transmissions, applied in vehicle gearboxes, motor vehicles, vehicle components, etc., can solve the problems of adjusting the reduction ratio, insufficient endurance, and reduced mileage, avoiding vibration or noise, and solving climbing jitters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

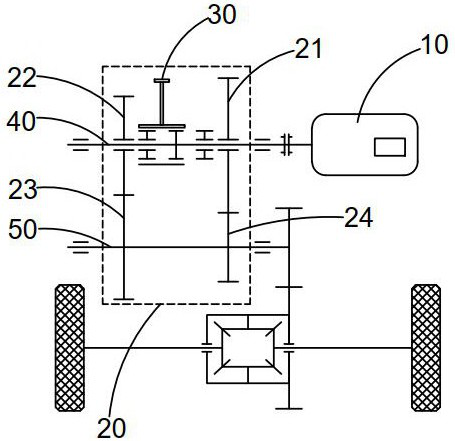

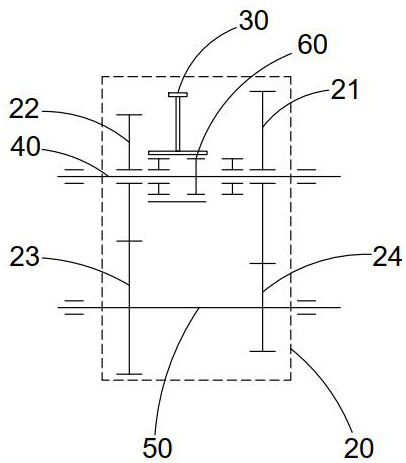

[0039] See attached manual Figure 1-4 shown, a two-speed transmission for new energy vehicles, including:

[0040] the first box 20,

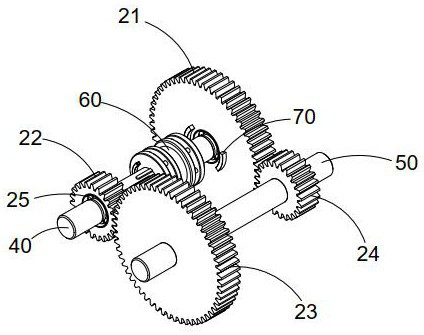

[0041] The first shaft body 40 , the first shaft body 40 passes through two opposite sides of the first box body 20 in sequence, and bearings are arranged at the joints. The second driving gear 22 and the first driving gear 21, the first shaft 40 between the second driving gear 22 and the first driving gear 21 is provided with a slidable shift assembly 60,

[0042] The second shaft body 50 , the second shaft body 50 passes through the two opposite sides of the first box body 20 in turn, and bearings are arranged at the joints, the second shaft body 50 is arranged parallel to the axis of the first shaft body 40 , and the second shaft body 50 A third driven gear 23 meshing with the second driving gear 22 and a fourth driven gear 24 meshing with the first driving gear 21 are provided,

[0043] Wherein, the second driving gear 22 and the first ...

Embodiment 2

[0057] This embodiment is further optimized on the basis of Embodiment 1 as follows: refer to the appendix of the description Figure 11 As shown, the side of the first driving gear 21 on which the first connecting block 70 is installed is provided with an auxiliary connecting ring 90, and the first connecting block 70 is connected with the side of the first driving gear 21 by fasteners. The connecting ring body 90 is arranged between the first connecting block 70 and the connecting side surface of the first driving gear 21 , the non-connecting part of the auxiliary connecting ring body 90 and the first connecting block 70 is bent upwards, and the bottom surface of the ring body is connected with the spring through the spring. The first driving gear 21 is laterally connected.

[0058] An auxiliary connecting ring body 90 is provided on the side of the second driving gear 22 on which the first connecting block 70 is installed. The first connecting block 70 is connected with the...

Embodiment 3

[0061] See attached manual Figure 1-4 shown, a two-speed transmission for new energy vehicles, including:

[0062] the first box 20,

[0063] The first shaft body 40 , the first shaft body 40 passes through two opposite sides of the first box body 20 in sequence, and bearings are arranged at the joints. The second driving gear 22 and the first driving gear 21, the first shaft 40 between the second driving gear 22 and the first driving gear 21 is provided with a slidable shift assembly 60,

[0064] The second shaft body 50 , the second shaft body 50 passes through the two opposite sides of the first box body 20 in turn, and bearings are arranged at the joints, the second shaft body 50 is arranged parallel to the axis of the first shaft body 40 , and the second shaft body 50 A third driven gear 23 meshing with the second driving gear 22 and a fourth driven gear 24 meshing with the first driving gear 21 are provided,

[0065] Wherein, the second driving gear 22 and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com