Single-component thermosetting packaging adhesive and preparation method thereof

A single-component, packaging adhesive technology, applied in the direction of adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the problems affecting the operability of the packaging process, the displacement of pins or terminals, and the increase of colloidal viscosity. Large and other problems, to achieve the effect of excellent insulation and mechanical properties, good fluidity, and reduced thermal expansion and contraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

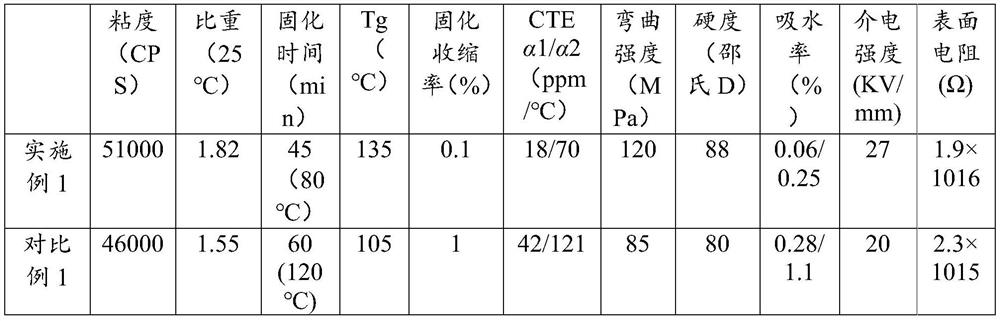

Examples

Embodiment 1

[0039] According to the formula in Table 1, pre-disperse 8170C epoxy resin, 8128 epoxy resin, E500 modified epoxy resin, BYK530 defoamer and BYK110 dispersant for 5 minutes until uniform; add carbon black T4 and 1175 spherical filler to disperse evenly, vacuum defoaming ; Add PN23J curing agent and 1021 curing agent to disperse evenly, vacuum defoam to obtain the product, and then store in separate packages at a storage temperature of 5°C. During the whole preparation process, pay attention to controlling the temperature of the material not to exceed 35°C.

[0040] Among them, the weight ratio of 1.0 μm, 5 μm and 40 μm spherical silica is 1:36:63.

[0041] Table 1 embodiment 1 each component addition formula

[0042] component name Parts by mass / Kg 8170C epoxy resin 60 8128 epoxy resin 20 E500 modified epoxy resin 20 BYK530 defoamer 0.2 BYK110 dispersant 0.8 1175 spherical packing 350 T4 carbon black 0.4 PN23J curing a...

Embodiment 2

[0044] On the basis of Example 1, the addition of each component in the formula in Table 1 is replaced by the addition of each component in Table 2.

[0045] Table 2 embodiment 2 each component addition formula

[0046] component name Parts by mass / Kg 8170C epoxy resin 50 8128 epoxy resin 25 E500 modified epoxy resin 25 BYK530 defoamer 0.2 BYK110 dispersant 0.8 1175 spherical packing 200 T4 carbon black 0.4 PN23J curing agent 20 1021 curing agent 5

Embodiment 3

[0048] On the basis of Example 1, the addition amount of each component in the formula in Table 1 is replaced by the addition amount of each component in Table 3.

[0049] Table 3 embodiment 3 each component addition formula

[0050] component name Parts by mass / Kg 8170C epoxy resin 50 8128 epoxy resin 30 E500 modified epoxy resin 20 BYK530 defoamer 0.2 BYK110 dispersant 0.8 1175 spherical packing 250 T4 carbon black 0.4 PN23J curing agent 20 1021 curing agent 7

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com