Two-frequency heat treatment and quenching process and device for D2 steel roller

A technology of quenching device and roll, which is applied in the fields of quenching process and device, heat treatment process and device, and can solve problems such as roll bending, low production capacity, and inability to meet technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with accompanying drawing:

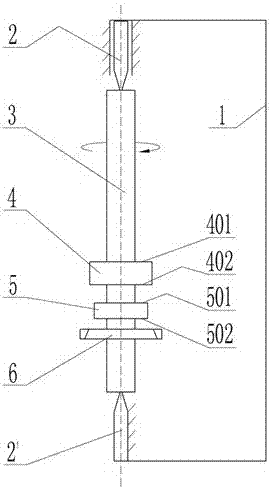

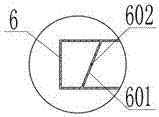

[0037] as attached figure 1 , 2 Shown, D 2 A device for dual-frequency heat treatment and quenching of steel rolls, including dual-frequency induction hardening machine tool 1, upper and lower clamping tips 2 and 2', upper heating sensor 4, lower heating sensor 5, water spray ring 6, upper clamping tip 2 and lower The tops of the clamping top 2' are facing each other, and the two tops are vertically supported on the working axis of the dual-frequency induction hardening machine tool 1; D 2 The steel roll 3 is clamped between the upper clamping tip 2 and the lower clamping tip 2' through the center holes at both ends; the upper heating sensor 4 and the lower heating sensor 5 are made of red copper, and the water spray ring 6 is made of stainless steel , the upper heating sensor 4, the lower heating sensor 5 and the water spray ring 6 are respectively along the working axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com