Soft bag infusion packaging system with high barrier property to gas and manufacturing method thereof

A soft bag infusion and packaging system technology, applied in the field of pharmaceutical packaging, can solve the problems of falling off, the surface of soda lime glass is susceptible to corrosion and changes, and achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples. Unless clearly defined otherwise, those skilled in the art should consider the chemical terms used throughout the description herein to have their ordinary meanings as used in the art.

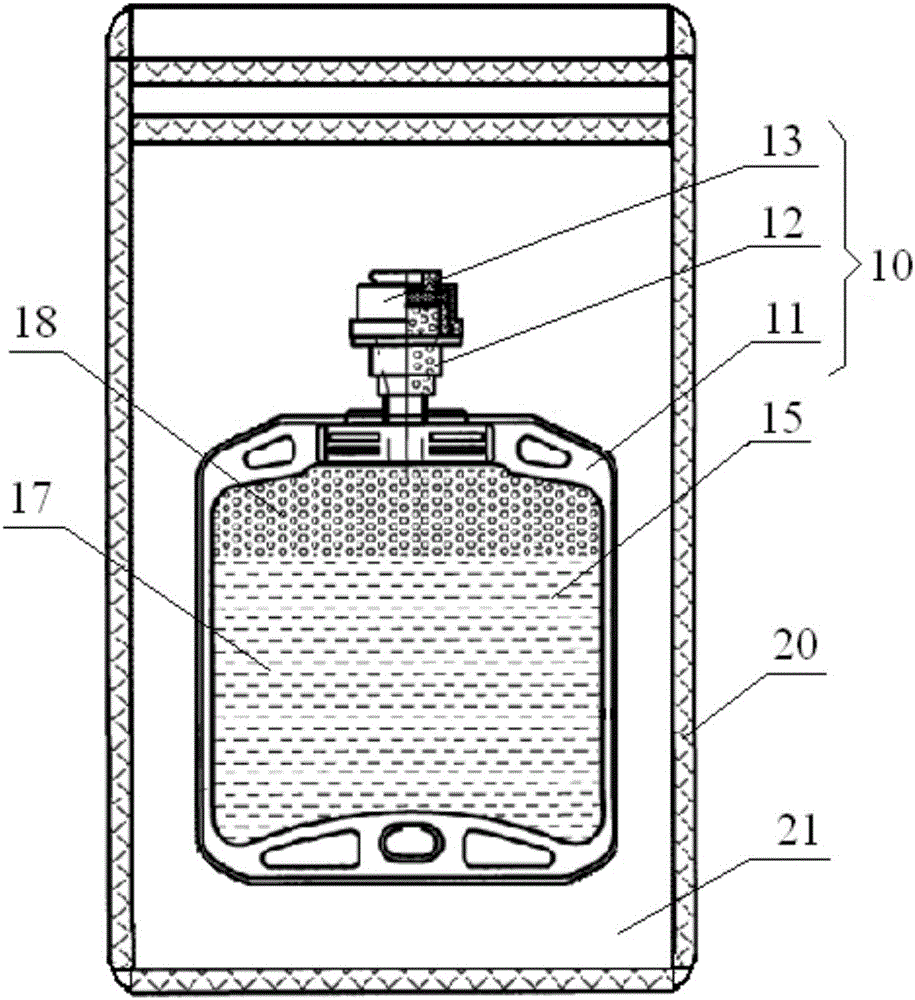

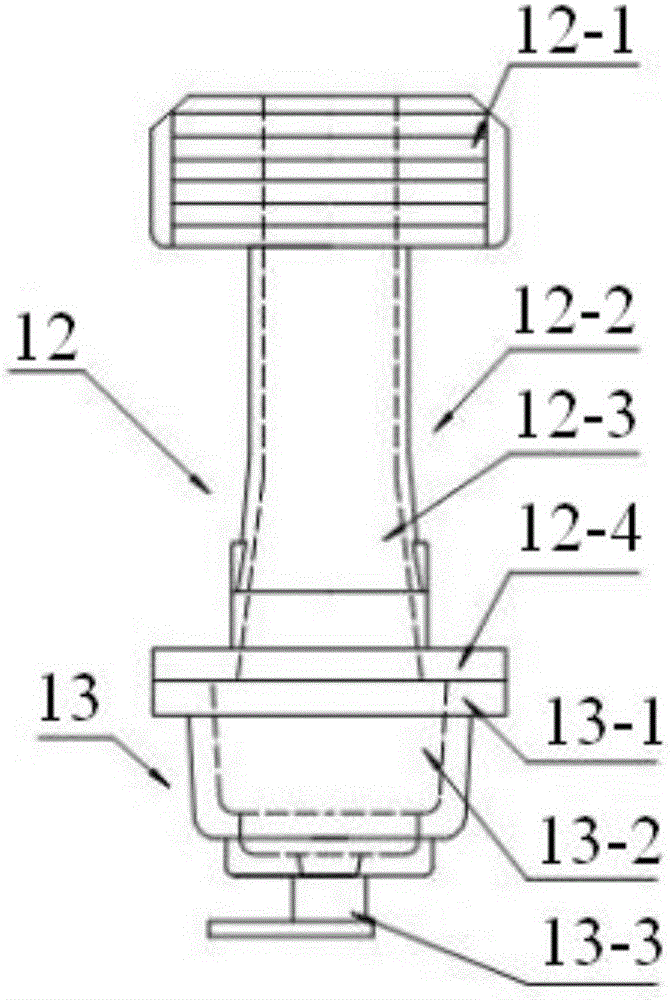

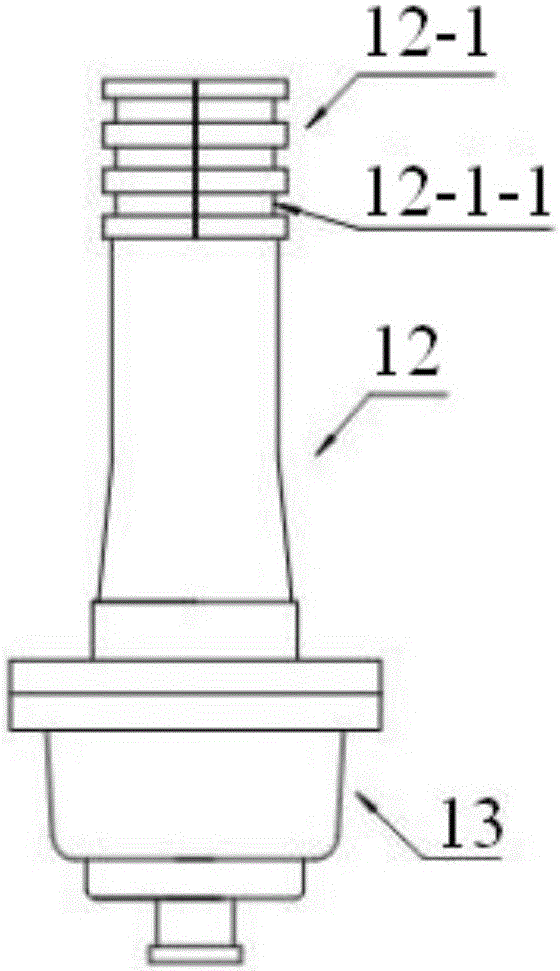

[0038] Such as figure 1As shown, in one embodiment of the present invention, a soft bag transfusion packaging system with high gas barrier properties is provided, the packaging system includes: a non-PVC co-extruded film inner bag 10 and a barrier protection bag 20 . Wherein the non-PVC co-extruded film inner bag 10 is provided with a medicament cavity 15 for containing the injection solution 17 and a protective gas 18; the barrier protection bag 20 is provided with a sealed cavity 21 for accommodating the non-P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper mouth diameter | aaaaa | aaaaa |

| Lower mouth diameter | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com