Preparation process of a p25-coated titanium dioxide nanotube array electrode material

A technology of nanotube array and titanium dioxide, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., to achieve highly ordered orientation characteristics, increase specific surface area, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Concrete processing steps of the present invention are as follows:

[0022](1). Mix and stir 0.44g ammonium fluoride and 88ml lactic acid until fully dissolved, then add 9.8ml dimethyl sulfoxide and stir as the electrolyte for preparing titanium dioxide nanotube arrays; the thickness is 0.25mm, and the purity is 99.99%. The titanium foil is cut into a rectangular square of 2.5cm×4cm, polished with metallographic sandpaper and an aqueous solution of hydrofluoric acid and nitric acid for chemical polishing, cleaning, and drying as an anode for anodic oxidation;

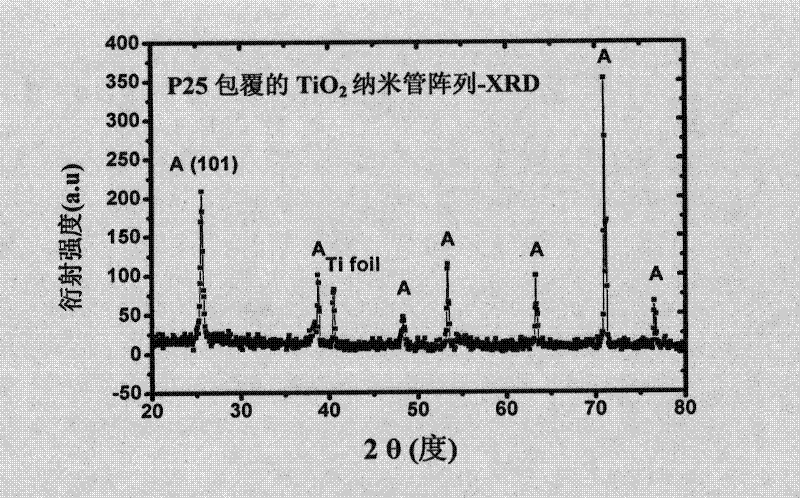

[0023] (2). Self-made an anodic oxidation tank, using a platinum electrode as the cathode, adding the above-mentioned prepared electrolyte, and at 35°C, apply a DC voltage of 55V to oxidize for 15 minutes and then adjust to a DC voltage of 45V to oxidize After 12 hours, an array of titanium dioxide nanotubes with an amorphous structure can be obtained; then, annealing at 420°C for 1 hour to obtain a crystallized ...

Embodiment 2

[0029] (1). Mix and stir 0.44g ammonium fluoride and 88ml lactic acid until fully dissolved, then add 9.8ml dimethyl sulfoxide and stir as the electrolyte for preparing titanium dioxide nanotube arrays; the thickness is 0.25mm, and the purity is 99.99%. The titanium foil is cut into a rectangular square of 2.5cm×4cm, polished with metallographic sandpaper and an aqueous solution of hydrofluoric acid and nitric acid for chemical polishing, cleaning, and drying as an anode for anodic oxidation;

[0030] (2). Self-made an anodic oxidation tank, using a platinum electrode as the cathode, adding the above-mentioned prepared electrolyte, and at 35°C, apply a DC voltage of 55V to oxidize for 15 minutes and then adjust to a DC voltage of 45V to oxidize After 12 hours, an array of titanium dioxide nanotubes with an amorphous structure can be obtained; then, annealing at 420°C for 1 hour to obtain a crystallized titanium dioxide nanotube array;

[0031] (3).Put 0.015M P25 into a beaker ...

Embodiment 3

[0036] (1). Mix and stir 0.44g ammonium fluoride and 88ml lactic acid until fully dissolved, then add 9.8ml dimethyl sulfoxide and stir as the electrolyte for preparing titanium dioxide nanotube arrays; the thickness is 0.25mm, and the purity is 99.99%. The titanium foil is cut into a rectangular square of 2.5cm×4cm, polished with metallographic sandpaper and an aqueous solution of hydrofluoric acid and nitric acid for chemical polishing, cleaning, and drying as an anode for anodic oxidation;

[0037] (2). Self-made an anodic oxidation tank, using a platinum electrode as the cathode, adding the above-mentioned prepared electrolyte, and at 35°C, apply a DC voltage of 55V to oxidize for 15 minutes and then adjust to a DC voltage of 45V to oxidize After 12 hours, an array of titanium dioxide nanotubes with an amorphous structure can be obtained; then, annealing at 420°C for 1 hour to obtain a crystallized titanium dioxide nanotube array:

[0038] (3).Put 0.015M P25 into a beaker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com