Multifunctional setting production line capable of producing pillow inners of high, medium and low densities

A low-density, multi-functional technology, applied in pillows and other directions, can solve the problems of mold blockage, small contact area, easy positioning, etc., to achieve the effect of changing comfort and quality, high degree of automation, and improving the quality of shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

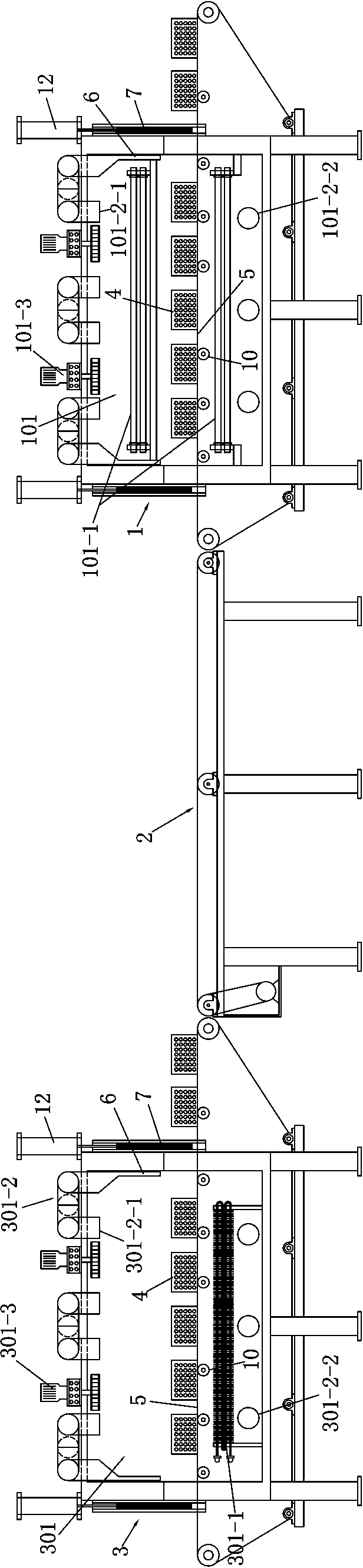

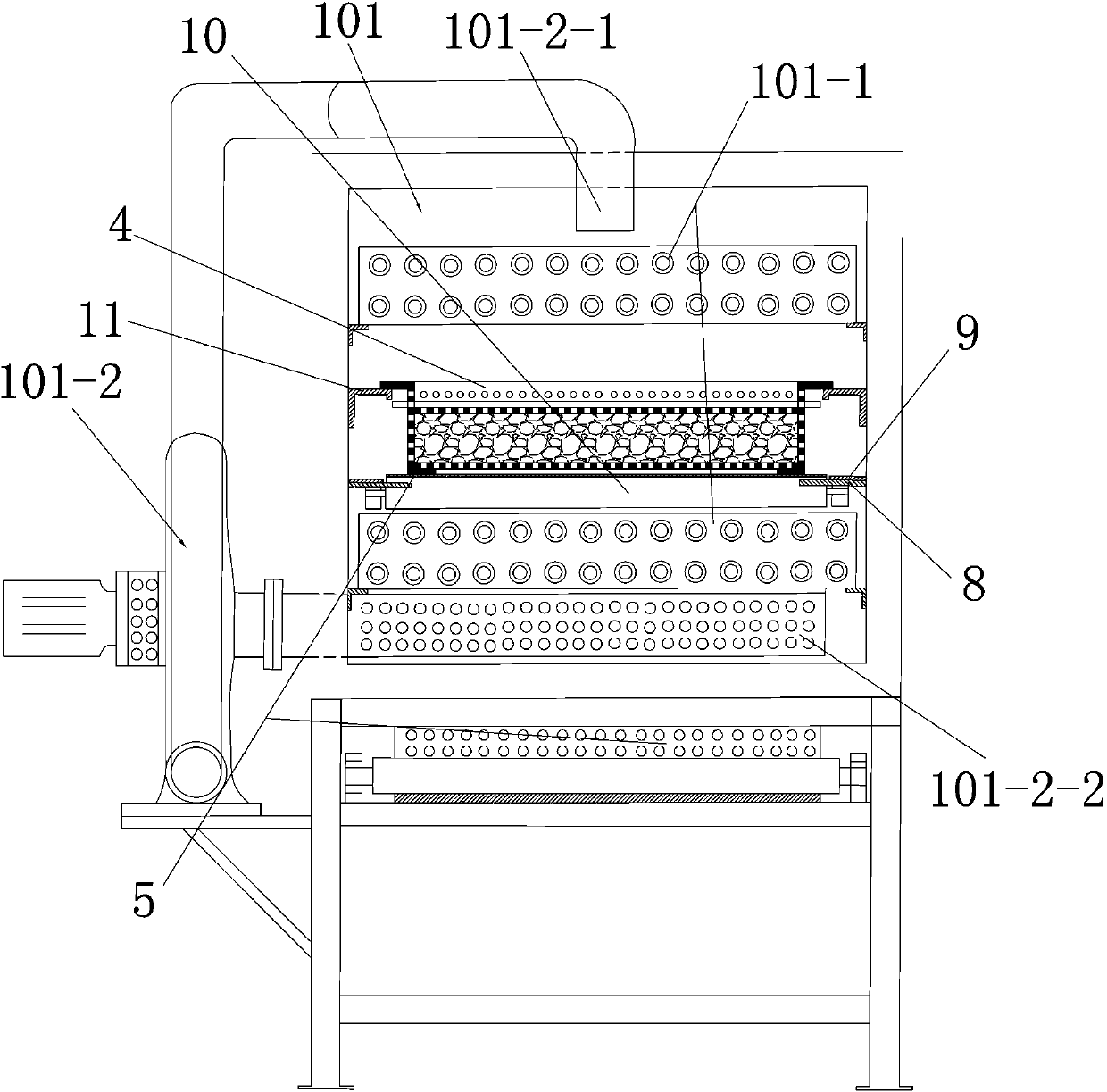

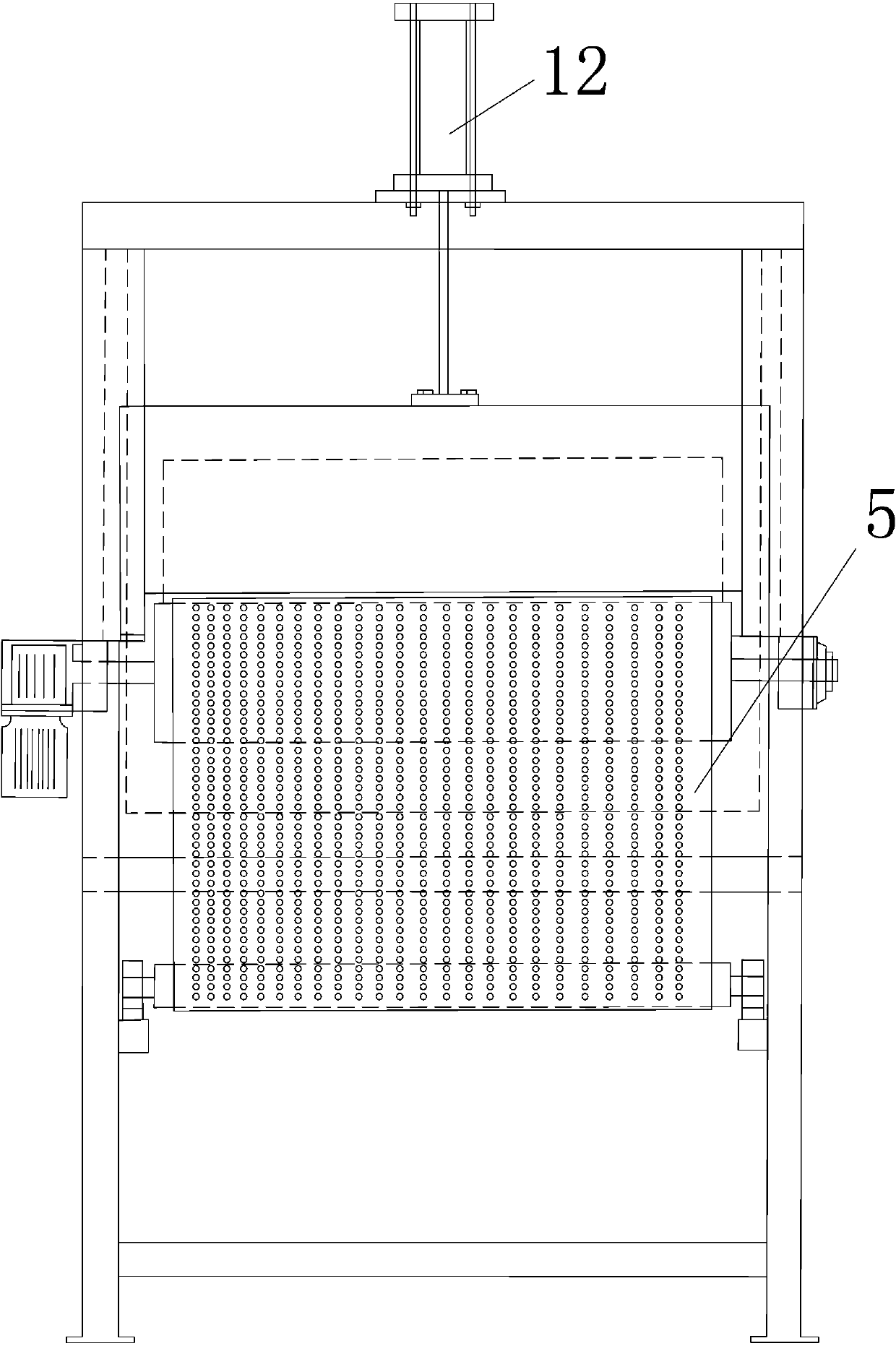

[0022] See attached figure 1 to attach Figure 7As shown, the multi-functional shaping production line that can produce high, medium and low density pillow cores described in this embodiment includes a heat-penetrating fiber material shaping machine 1, a natural cooling belt 2, a cold-penetrating fiber material machine 3 and Porous air-permeable shaping mold 4, the natural cooling zone 2 is correspondingly arranged between the heat-penetrating fiber material shaping machine 1 and the cold-penetrating fiber material machine 3, and is connected with the heat-penetrating fiber material shaping machine 1 and the cold-penetrating fiber material machine respectively. The material machine 3 is connected to realize the transition from the porous air-permeable shaping mold 4 coming out of the heat-penetrating fiber material machine 1 to the cold-penetrating fiber material machine 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com