Autoignition dual ring fast cutting torch

A technology of automatic ignition and rapid cutting, applied in the direction of gas fuel burner, combustion method, combustion type, etc., can solve the problems of high cost, high difficulty in promotion, complex technology, etc., and achieve reduced oxygen consumption, high safety, and reduced consumption. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

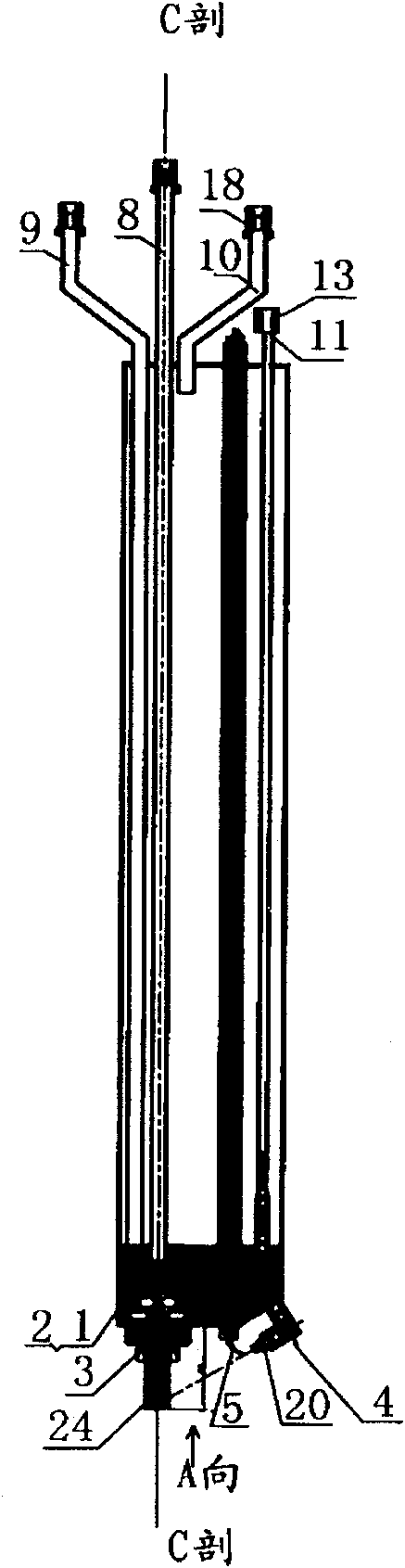

[0046] Embodiments of the present invention are specifically described below in conjunction with the accompanying drawings:

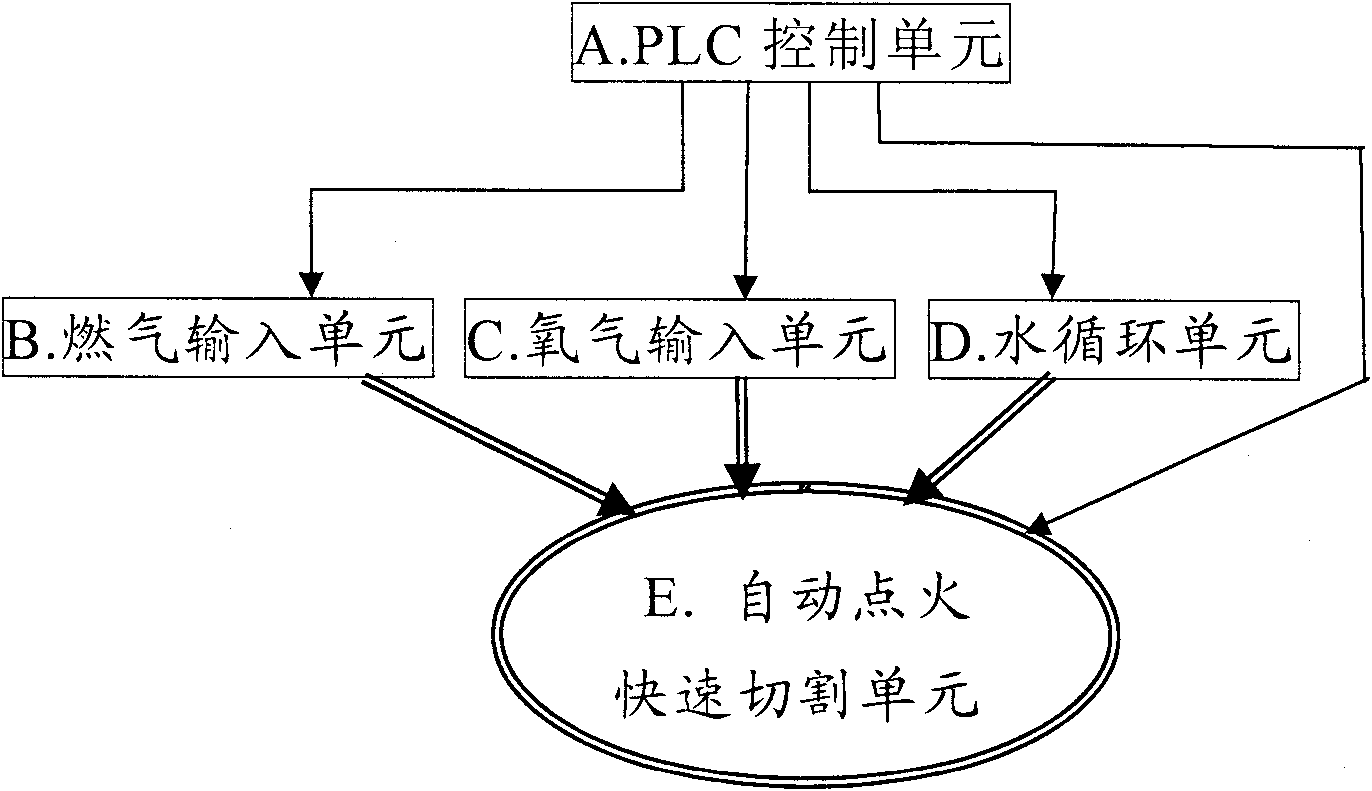

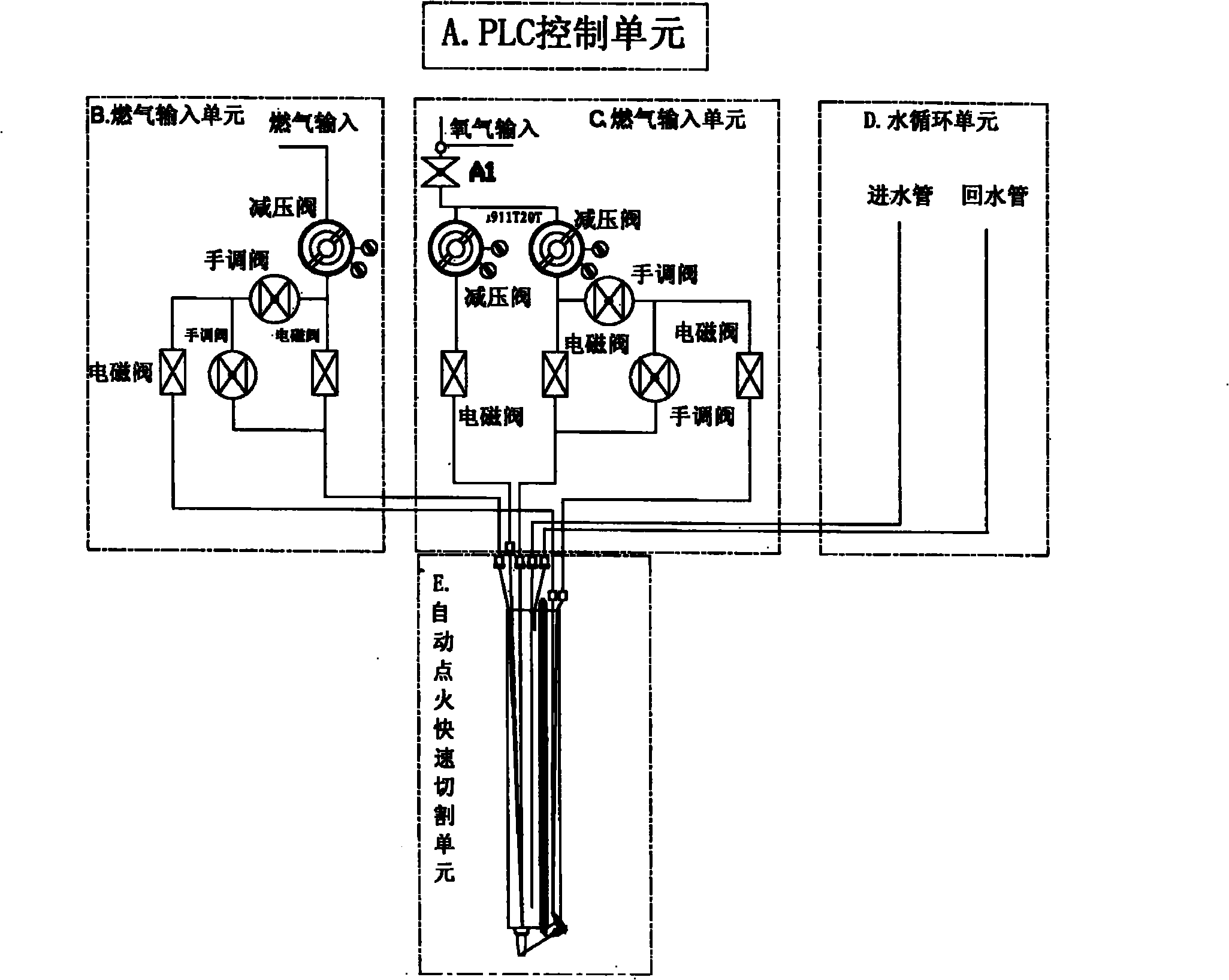

[0047] Reference attached figure 1 , 2 , The embodiment of the present invention is composed of five parts: PLC control unit A, gas input unit B, oxygen input unit C, water circulation unit D, and automatic ignition quick cutting unit E. Among them, the PLC control unit A is electrically connected to the solenoid valve in the gas input unit B and the oxygen input unit C, and is electrically connected to the ignition gun in the automatic ignition quick cutting unit E; the gas input unit B, the oxygen input unit C, and the water circulation unit D The output end of the pipeline in is also communicated with the corresponding gas, oxygen, and water pipeline input ends in the automatic ignition quick cutting unit E.

[0048] In the embodiment of the present invention, the PLC control unit A is provided with two working modes, manual and automatic, and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com