Sintered flux for welding of high-strength steel for ocean engineering and preparation method of sintered flux

A technology of sintering flux and marine engineering, which is applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problems of limited application range and imperfection, and achieve the effects of stable arc, uniform flux particle size, and beautiful weld bead formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific embodiments.

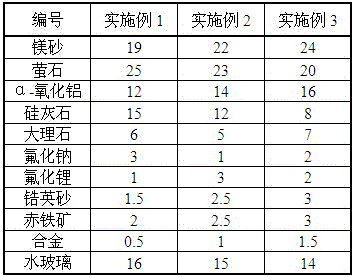

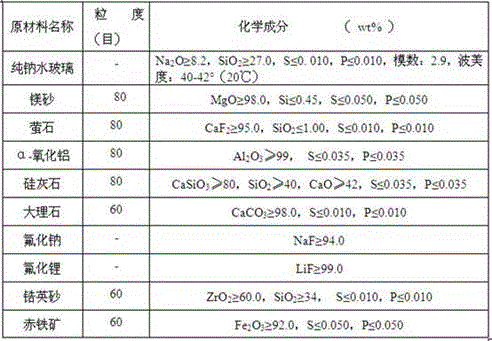

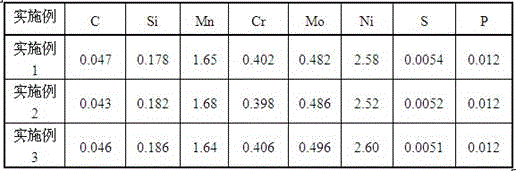

[0020] A sintered flux used for welding high-strength steel in marine engineering. It belongs to the fluorine-alkali type sintered flux. It is composed of the following components in parts by weight: MgO 19-24 parts, CaF 2 20-25 copies, Al 2 O 3 12~16 parts, SiO 2 4~8 parts, CaO8~10 parts, BaO2~4 parts, NaF1~3 parts, LiF 1-3 parts, ZrO 2 1-2 parts, Fe 2 O 3 2-3 parts, 0.5~1.5 parts of alloy and 14-16 parts of water glass. The sintered flux, flux slag is mainly composed of MgO-CaO-BaO-CaF 2 -Al 2 O 3 -SiO 2 Department of composition.

[0021] The method of adding each component of the flux of the present invention is as follows: MgO is in the form of magnesia; CaF2 is in the form of fluorite, Al 2 O 3 In the form of α-alumina, SiO 2 In the form of wollastonite, CaO in the form of wollastonit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com