Making method for concave-convex elastic real silk jacquard fabric

A technology of jacquard fabrics and production methods, which is applied to the direction of digging fabrics, fabrics, embossed fabrics, etc., which can solve difficult problems and achieve the effects of high efficiency, comfortable hand feeling and short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, and the following embodiments are explanations of the present invention and the present invention is not limited to the following embodiments.

[0017] A method for making a concave-convex elastic silk jacquard fabric of the present embodiment comprises the following steps:

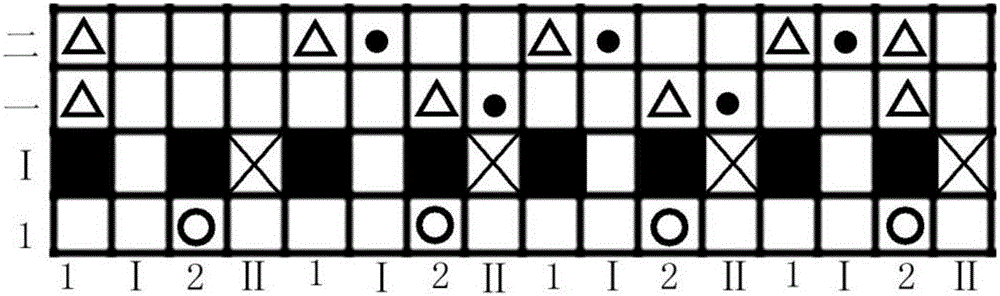

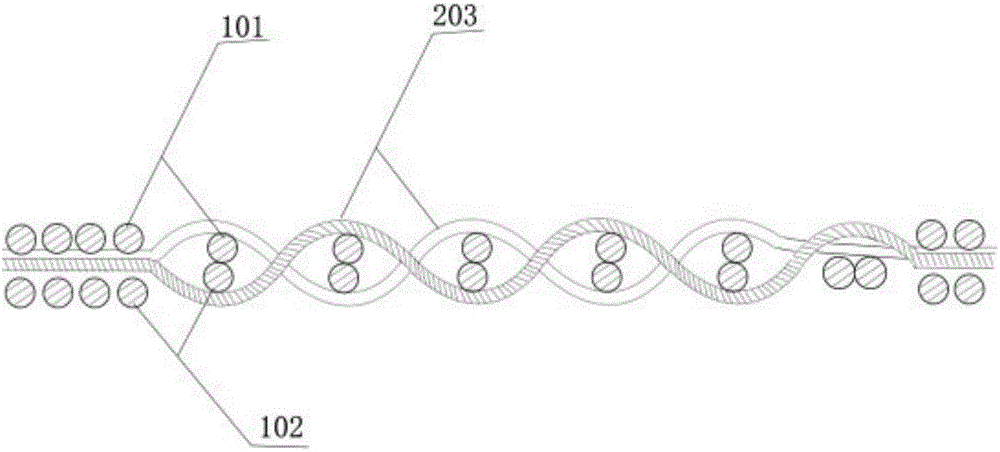

[0018] 1) Formulation of the overall process specification; adopt the following overall specification design: determine the type and yarn count specification of the warp and weft yarns; determine the inner width of the finished product; determine the square meter weight of the finished product; determine the warp and weft density; Combination mode and components of warp and weft;

[0019] This embodiment adopts the following overall process specification design:

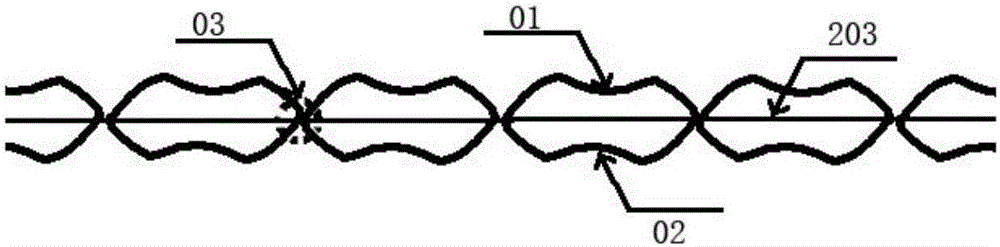

[0020] Now take the "Ring Mountain" pattern with an inner width of 249CM as an example, which is applied to the field of home textiles s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com