Millimeter wave band traveling wave tube output window and manufacturing method thereof

A millimeter-wave band and output window technology, which is applied in the manufacture of discharge tubes/lamps, cold cathodes, and electrode systems, can solve problems such as loose fitting structures, poor matching of vacuum airtight electrical properties, and weak welding, etc., to achieve Good effect of vacuum airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

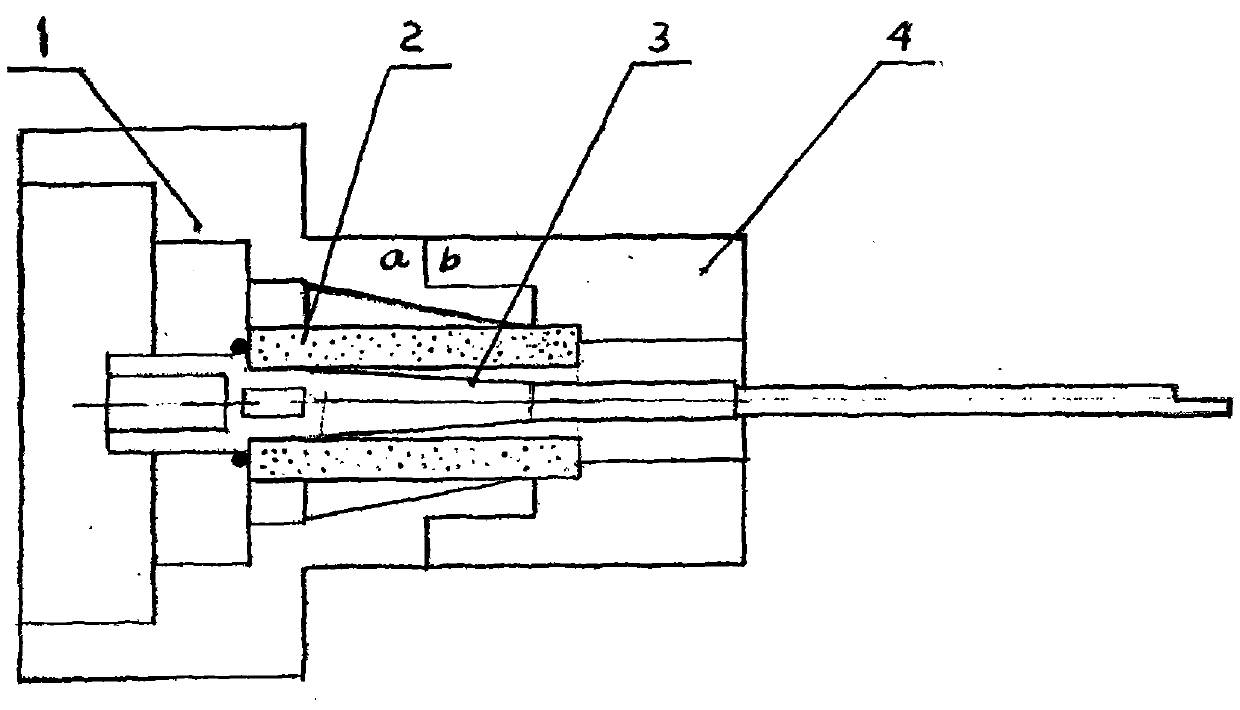

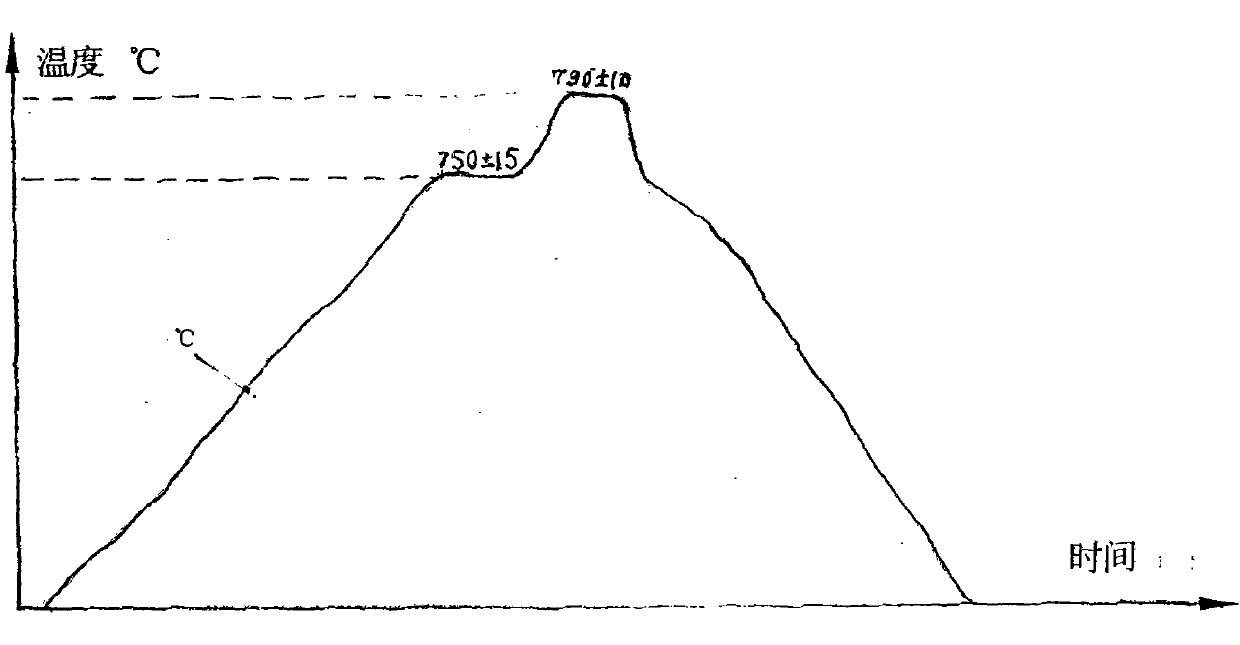

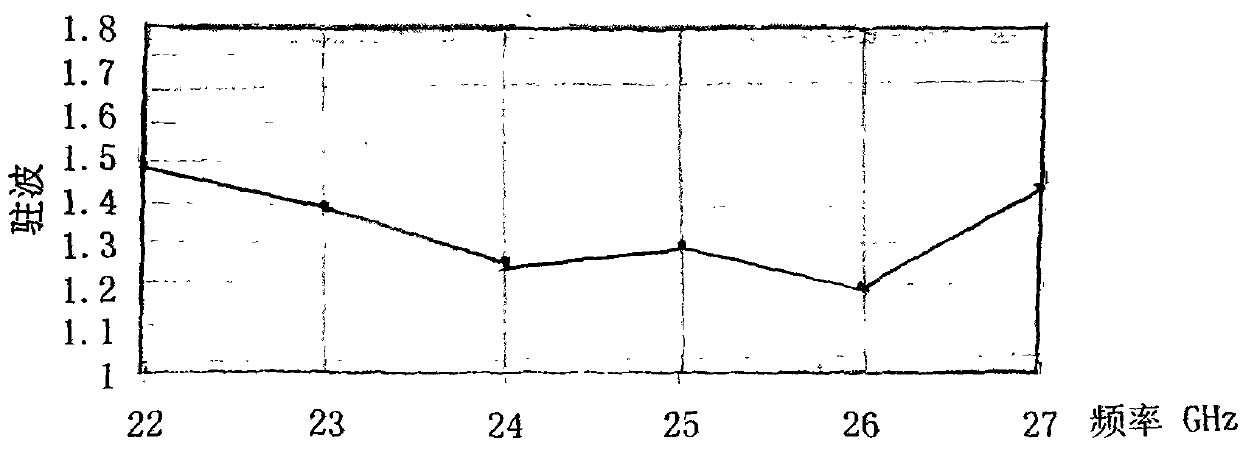

[0022] The technical solution of the present invention is to use electromagnetic simulation software to design the structure, design the inner conductor, dielectric ceramic and outer conductor in the overall structure of the energy output window assembly, and assemble them with a fixture and weld them according to the welding process to obtain good air tightness The output window is finished, and its performance meets the requirements of the standing wave within the bandwidth of the working frequency band of the ka-band traveling wave tube (the low-frequency end of the millimeter-wave band).

[0023] refer to figure 1 , showing the structure diagram of the output window of the millimeter-wave band traveling wave tube of the present invention. In the figure, the stepped cylindrical outer conductor a placed on the outermost side is 1, and the outer conductor b connected to it is the outer conductor b. The central part of the output window is the core A rod-shaped inner conductor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air tightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com