A kind of preparation method of nano waterproof membrane of military equipment

A technology of waterproof membrane and waterproof membrane layer, applied in nanotechnology, metal material coating technology, vacuum evaporation plating and other directions, can solve the problems of poor ventilation effect of plastic sealing ring, expensive EPTFE material, high heating performance requirements, etc. To achieve the effect of favorable adhesion and growth, good waterproof effect and good vacuum air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A method for preparing a nano waterproof membrane for military equipment, comprising the following steps:

[0059] 1) The surface of the military equipment to be coated is ultrasonically cleaned and dried with a cleaning agent; the drying temperature after cleaning is 35°C, and the drying time is 20 minutes.

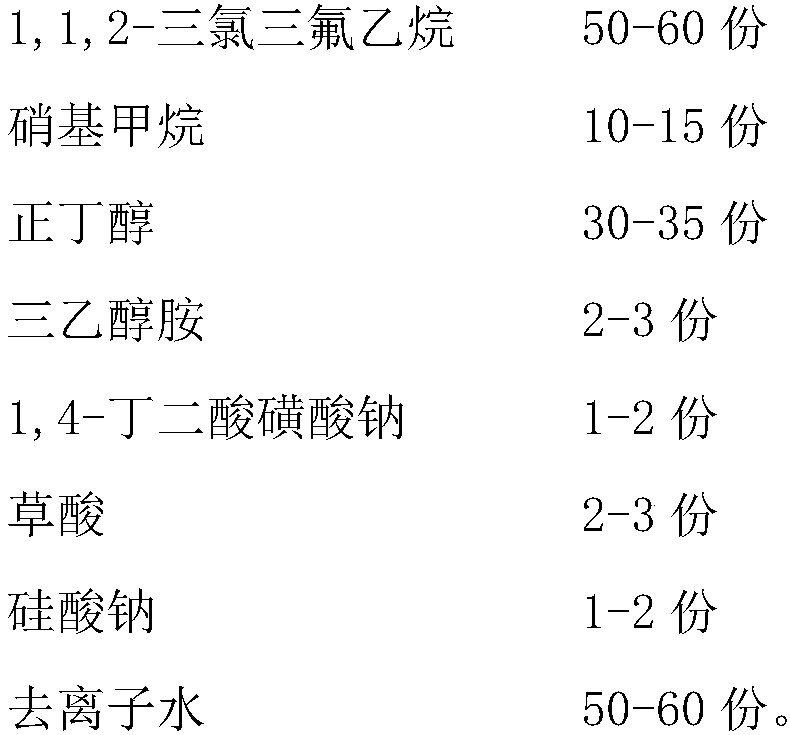

[0060] The cleaning agent is mixed by the following raw materials in parts by weight:

[0061] 1,1,2-Trichlorotrifluoroethane 50 parts

[0062] Nitromethane 15 parts

[0063] 30 parts of n-butanol

[0064] 3 parts triethanolamine

[0065] Sodium 1,4-butanedioic acid sulfonate 1 part

[0066] 3 parts oxalic acid

[0068] 60 parts deionized water

[0069] 2) Put the military equipment to be coated into the vacuum coating chamber, heat and vacuum;

[0070] 3) Put the first coating raw material into the evaporation chamber, the temperature of the cold pump before putting the coating raw material is below -30°C, continue to vacuu...

Embodiment 2

[0074] A method for preparing a nano waterproof membrane for military equipment, comprising the following steps:

[0075] 1) The surface of military equipment to be coated is ultrasonically cleaned and dried with a cleaning agent; the drying temperature after cleaning is 40°C, and the drying time is 25 minutes.

[0076] The cleaning agent is mixed by the following raw materials in parts by weight:

[0077] 1,1,2-Trichlorotrifluoroethane 60 parts

[0078] Nitromethane 10 parts

[0079] 35 parts of n-butanol

[0080] 2 parts triethanolamine

[0081] Sodium 1,4-butanedioic acid sulfonate 2 parts

[0082] oxalic acid 2 parts

[0083] Sodium silicate 2 parts

[0084] 50 parts of deionized water

[0085] 2) Put the military equipment to be coated into the vacuum coating chamber, heat and vacuum;

[0086] 3) Put the first coating raw material into the evaporation chamber, the temperature of the cold pump before putting the coating raw material is below -30°C, continue to vacu...

Embodiment 3

[0090] A method for preparing a nano waterproof membrane for military equipment, comprising the following steps:

[0091] 1) The surface of the military equipment to be coated is ultrasonically cleaned and dried with a cleaning agent; the drying temperature after cleaning is 37°C, and the drying time is 22 minutes.

[0092] The cleaning agent is mixed by the following raw materials in parts by weight:

[0093] 1,1,2-Trichlorotrifluoroethane 55 parts

[0094] Nitromethane 12 parts

[0095] 32 parts of n-butanol

[0096] 2.5 parts of triethanolamine

[0097] Sodium 1,4-butanedioic acid sulfonate 1.5 parts

[0098] 2.5 parts of oxalic acid

[0099] Sodium silicate 1.5 parts

[0100] 55 parts of deionized water

[0101] 2) Put the military equipment to be coated into the vacuum coating chamber, heat and vacuum;

[0102] 3) Put the first coating raw material into the evaporation chamber, the temperature of the cold pump before putting the coating raw material is below -30°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com