Modified superfine zinc oxide and its prepn

A zinc oxide and modification technology, applied in the direction of zinc oxide/zinc hydroxide, fibrous fillers, etc., can solve the problems of large specific surface area and surface energy, hindering the performance of ultrafine powder, and small particle size of ultrafine powder. , to achieve the effect of good dispersion, strong functionality and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

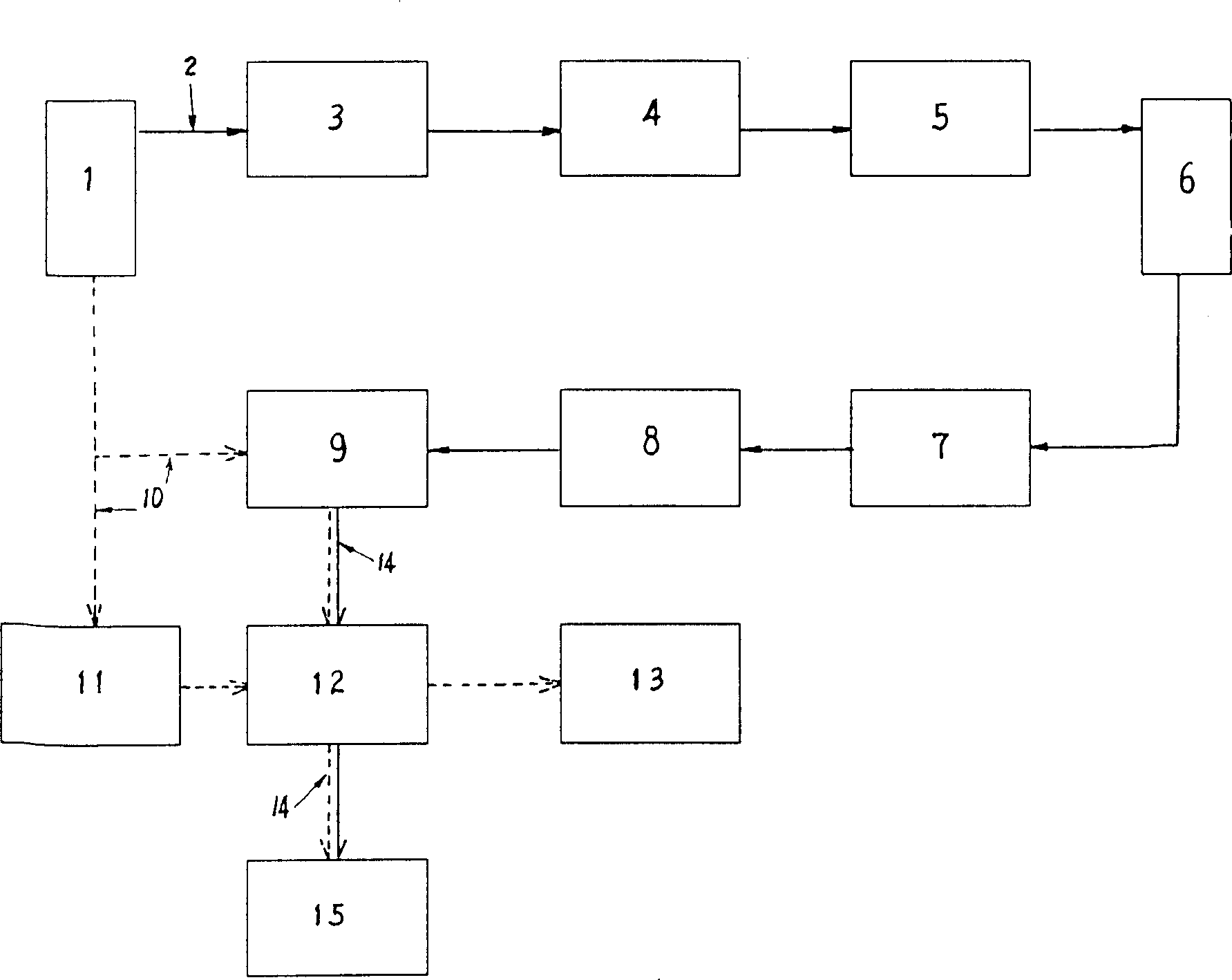

Image

Examples

Embodiment 1

[0020] ①Preparation method of modified nanoscale and submicron ultrafine zinc oxide:

[0021] In this example, the modified ultrafine zinc oxide is prepared by a wet method: with C 16-18 Ammonium stearate, or alkylbenzene sulfonate, or alkyl ether phosphate, or alcohol ether carboxylate, and prepare them to 0.1mol / L, or 0.5mol / L, or 0.8mol / L , or the modifier of 1mol / L, the zinc-ammonia complex solution in the ammonia distillation equipment is added into the modified solvent, and its content is 0.5%, or 5%, or 15%, or 20% (weight) of the zinc oxide content %) of ammonium stearate, or alkyl benzene sulfonate, or alkyl ether phosphate, or alcohol ether carboxylate, add a modified solvent and start stirring, heating up, when the temperature rises to 80-90 ° C Ammonia distillation at constant temperature, when the content of ammonia is less than 5% (percentage by weight), the ammonia distillation is completed, and after precipitation, impurity removal, purification, drying and ca...

Embodiment 2

[0025] ①Preparation method of modified nanoscale and submicron ultrafine zinc oxide:

[0026] In this example, the modified ultrafine zinc oxide is prepared by a wet method: polyethylene glycol (M=400) or fatty alcohol polyoxyethylene ether is dissolved in a certain amount of deionized water to prepare 0.2mol / L, or 0.5 mol / L, 0.7mol / L added solution. Take by weighing the polyethylene glycol solution of 2%, or 4%, or 10%, or 18% (percentage by weight) relative to the zinc oxide content in the zinc ammonia complex solution, or the fatty alcohol polyoxyethylene ether solution is added to In the zinc-ammonia complex solution in the ammonia distillation equipment, the rest of the preparation steps are the same as in Example 1 to obtain the modified ultrafine zinc oxide powder.

[0027] ②Modified nanoscale and submicron ultrafine zinc oxide:

[0028] Add polyethylene glycol or aliphatic alcohol polyoxyethylene ether with non-ionic surface modification solvent to modify ultrafine z...

Embodiment 3

[0030] ①Preparation method of modified nanoscale and submicron ultrafine zinc oxide:

[0031] In this example, the modified ultrafine zinc oxide is prepared by a wet method: water-soluble titanate, or silane, or aluminate ester coupling agent is dissolved in a certain amount of ionized water, and the preparation ratio is by weight: titanate ( or silane, or aluminate): water = 1:10 (or 1:1, or 1:5, or 1:20), prepared into a certain concentration of titanate (or silane, or aluminate) water solvent . Get 0.1%, or 2%, or 6%, or 10%, or 20% (percentage by weight) of titanate, or silane, or aluminate ester solvent relative to the content of zinc oxide in the zinc-ammonia complex solution, add into the zinc-ammonia complex solution in the ammonia distillation equipment, and the rest of the preparation steps are the same as in Example 1 to obtain the modified ultrafine zinc oxide powder.

[0032] ②Modified nanoscale and submicron ultrafine zinc oxide:

[0033] Water-soluble titanat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com