Method for manufacturing pattern card of jacquard fabric with straight stitching effect

A technology of jacquard fabric and production method, which is applied in the direction of pattern board, textile, textile and paper making, etc., can solve the problem of pattern layout limitation, and achieve the effect of clear graphic edge, avoidance of skipping and jaggies, and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

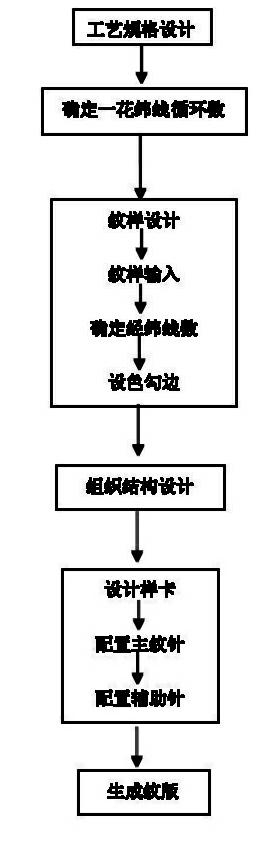

[0021] A method for making a pattern plate of a straight needle embroidery effect jacquard fabric in this embodiment, such as figure 1 As shown, it includes the following process steps: (1) Determine the parameters of the small sample through the design of the process specification, and calculate the number of circulating wefts of the small sample; (2) Design the cardboard according to the parameters of the small sample and the number of circulating wefts of the small sample; (3) Then through the organizational structure Design for pattern making; (4) Generate pattern.

[0022] Firstly, the cycle number of one flower weft is determined through the process specification design, which refers to determining the warp shrinkage and weft shrinkage according to the width of the upper machine and the width of the finished product, and then according to the warp yarn used, the type of weft yarn, yarn count, warp and weft density and a pattern The number of stitches is used to determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com