Production management device, method and system

A production management and production system technology, applied in manufacturing computing systems, general control systems, closed-circuit television systems, etc., can solve problems such as time-consuming work, and achieve the effect of reducing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

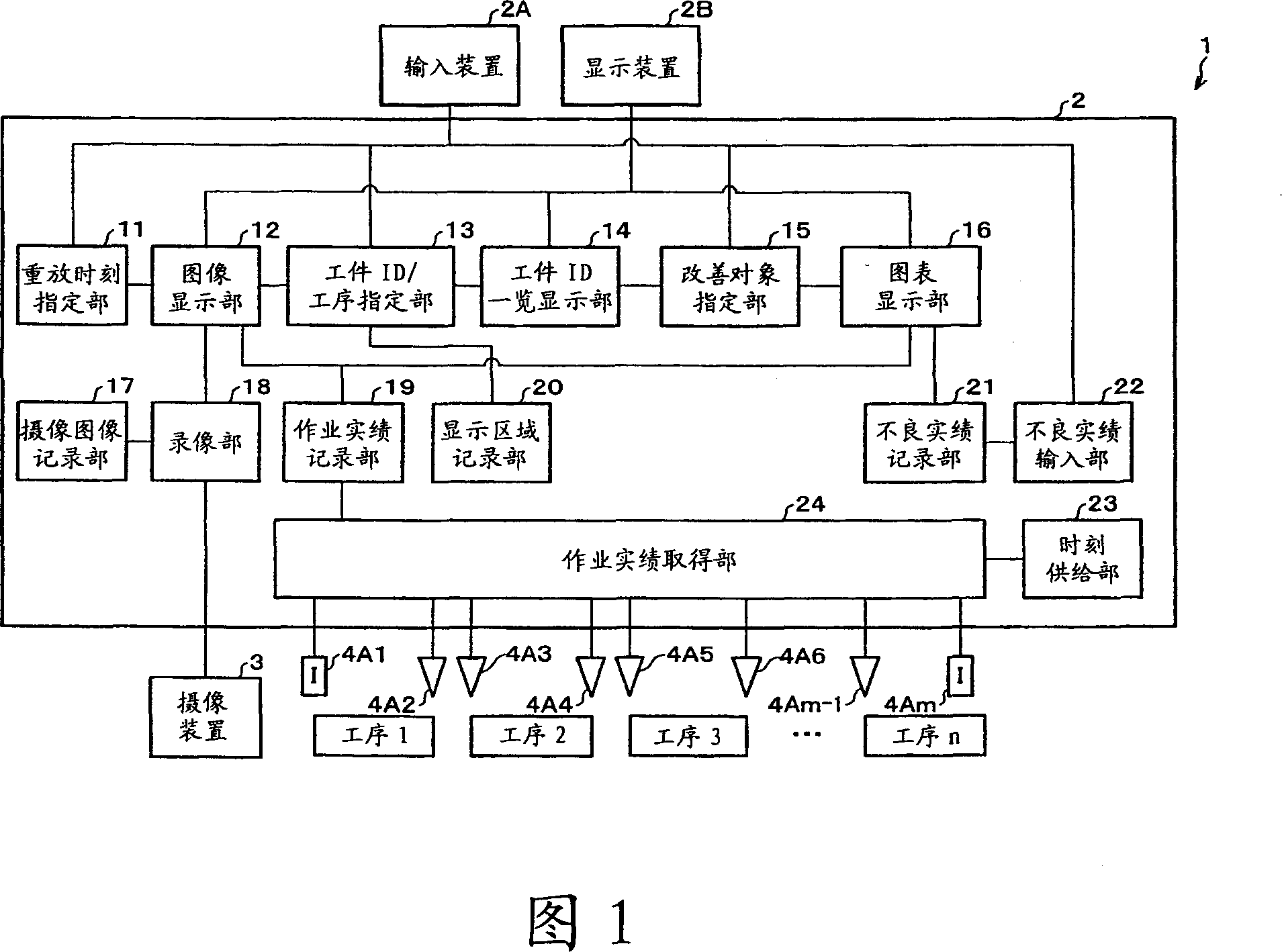

[0106] One embodiment of the present invention will be described below with reference to the drawings. In this embodiment, as an example, a production management device applied to a production system having a manual assembly line composed of n steps will be described.

[0107] (Structure of production system)

[0108] First, a production system 1 for a certain product to which the production management device 2 of this embodiment is applied will be described with reference to FIG. 1 . In the example shown in FIG. 1, the structure of the production system 1 is as follows: a production line; which includes n processes (process 1 to process n) for manufacturing products through the manual work of workers; a production management device 2 that monitors The operation of each process helps to analyze the cause of the failure; and the imaging device 3 photographs the operation status in each process on the production line.

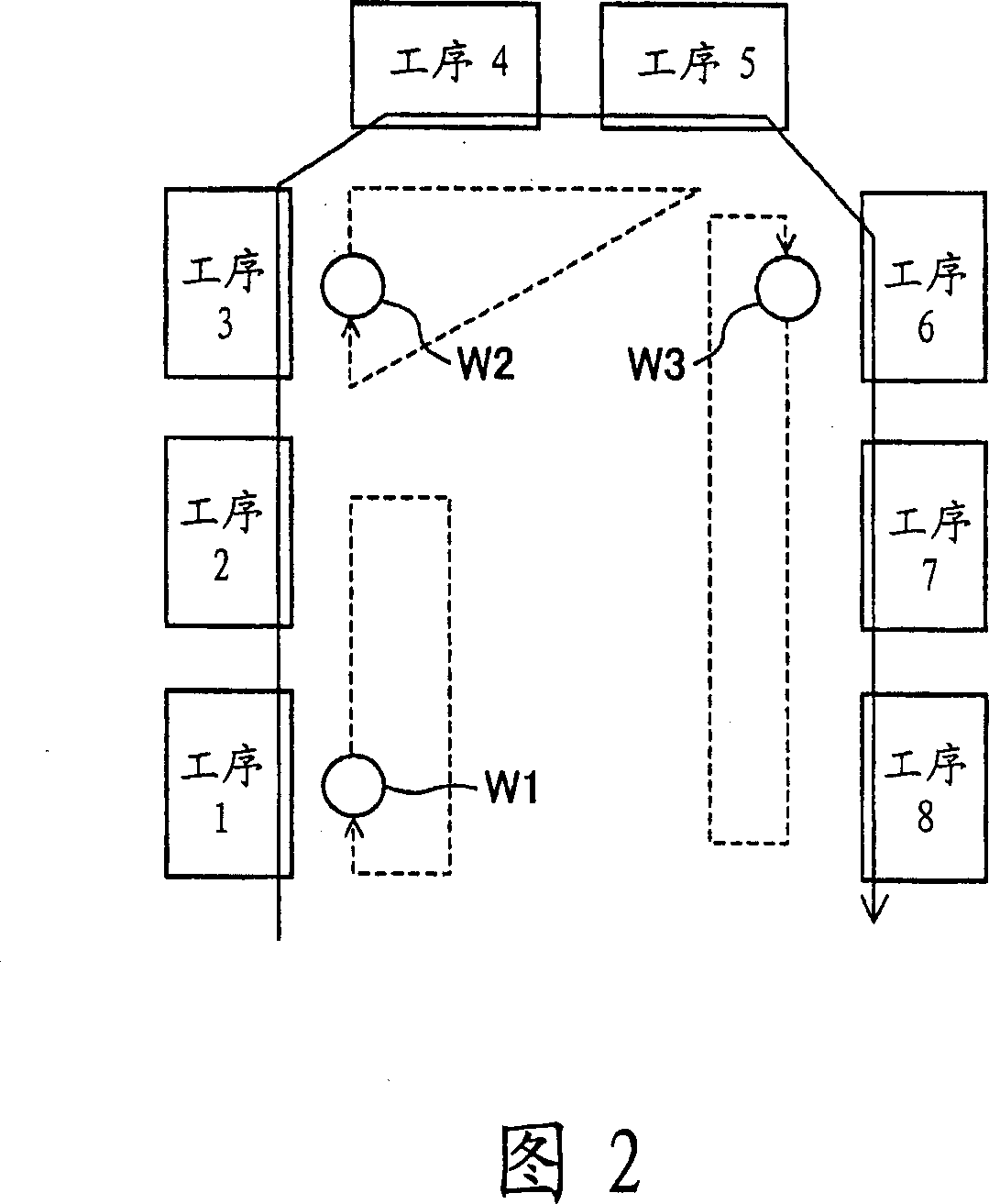

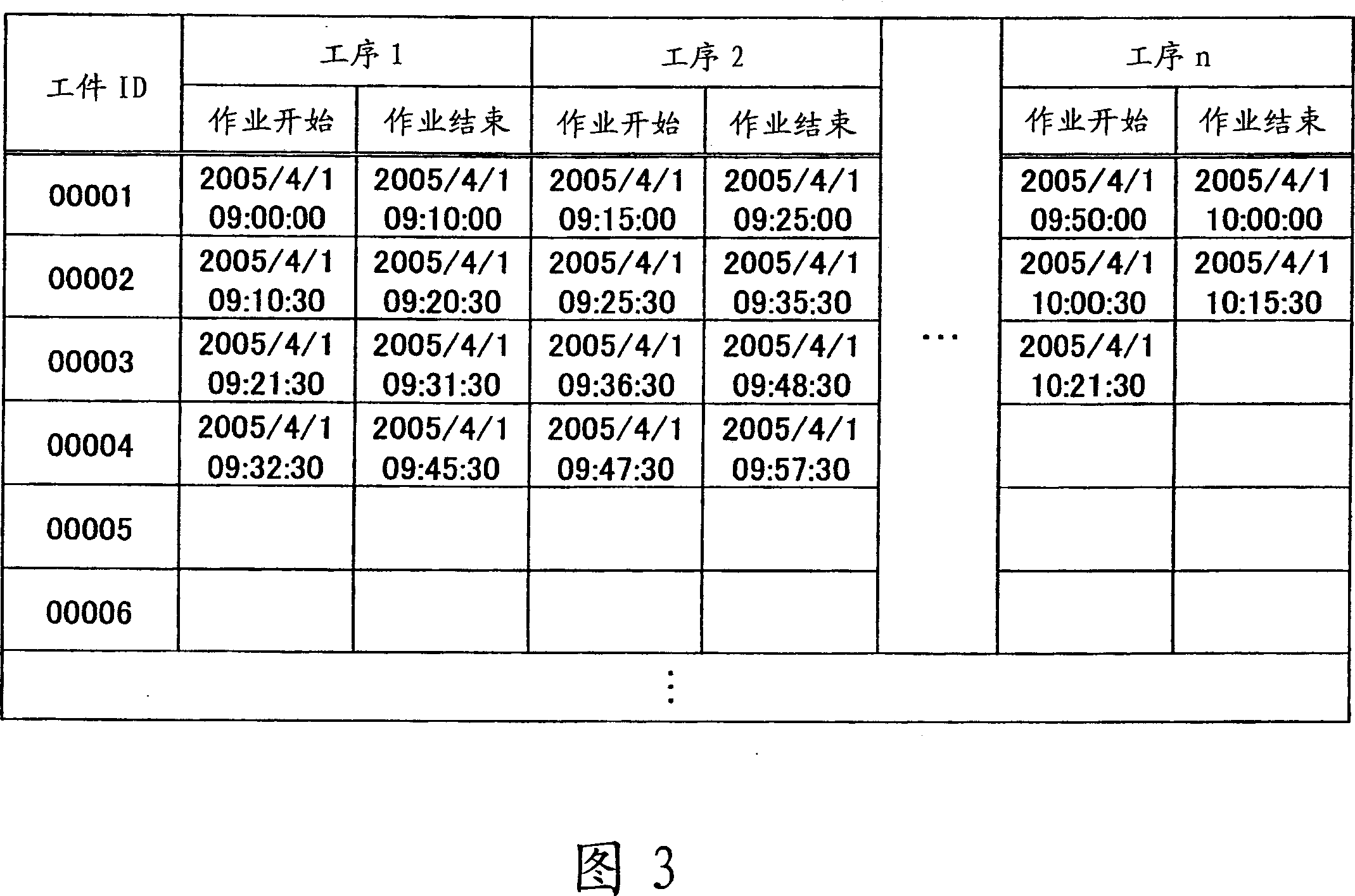

[0109] Process 1 to process n are arranged in order from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com