UV printing ink printing art of forming texture

A technology of ink printing and process, applied in the direction of printing process, printing, printing post-processing, etc., can solve the problems of poor decoration, increased waste rate, and lower printing quality, so as to reduce the time of high temperature exposure, avoid deformation or Baked, visually obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The processing steps of the first specific embodiment of the present invention are as follows successively:

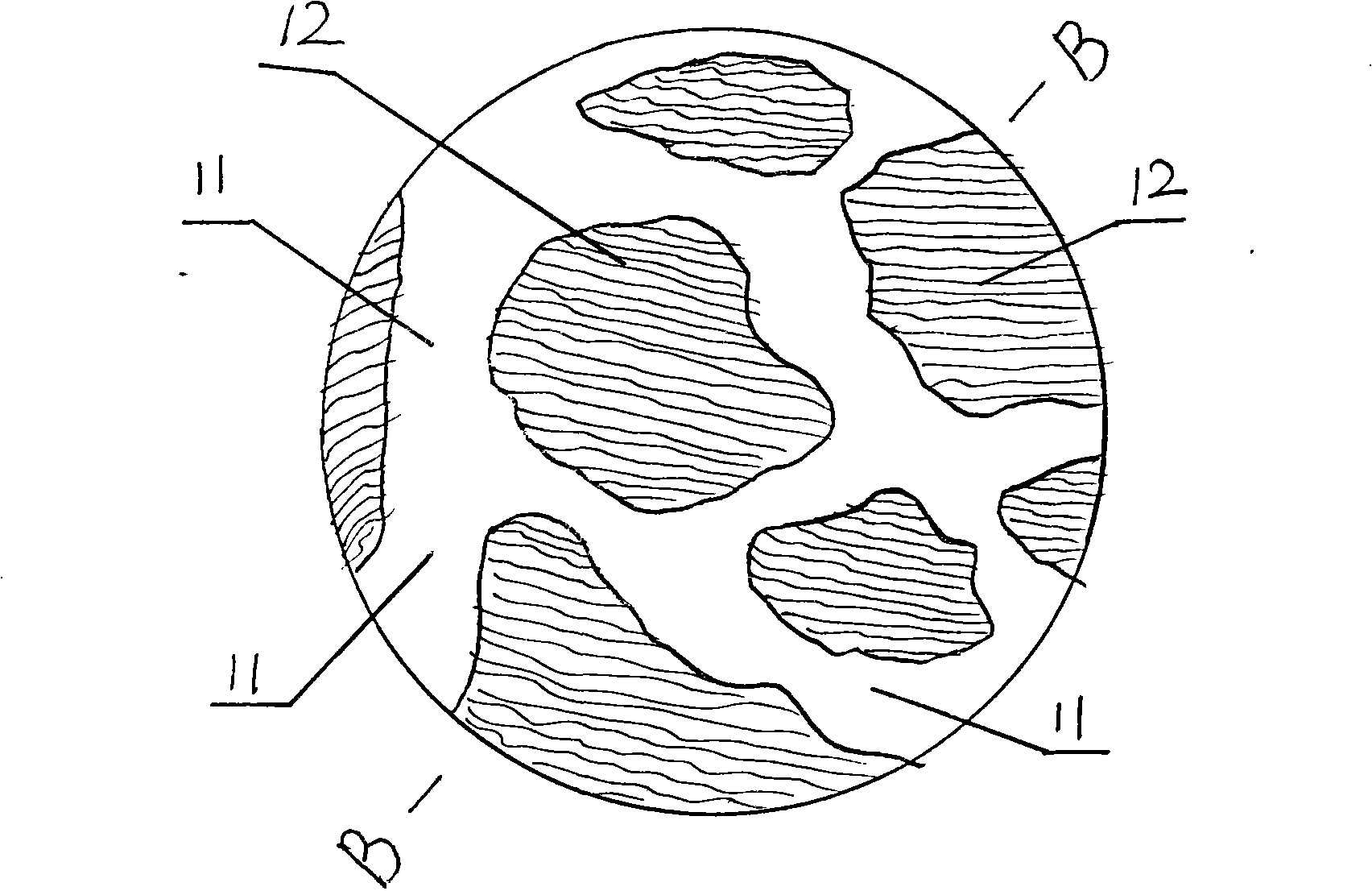

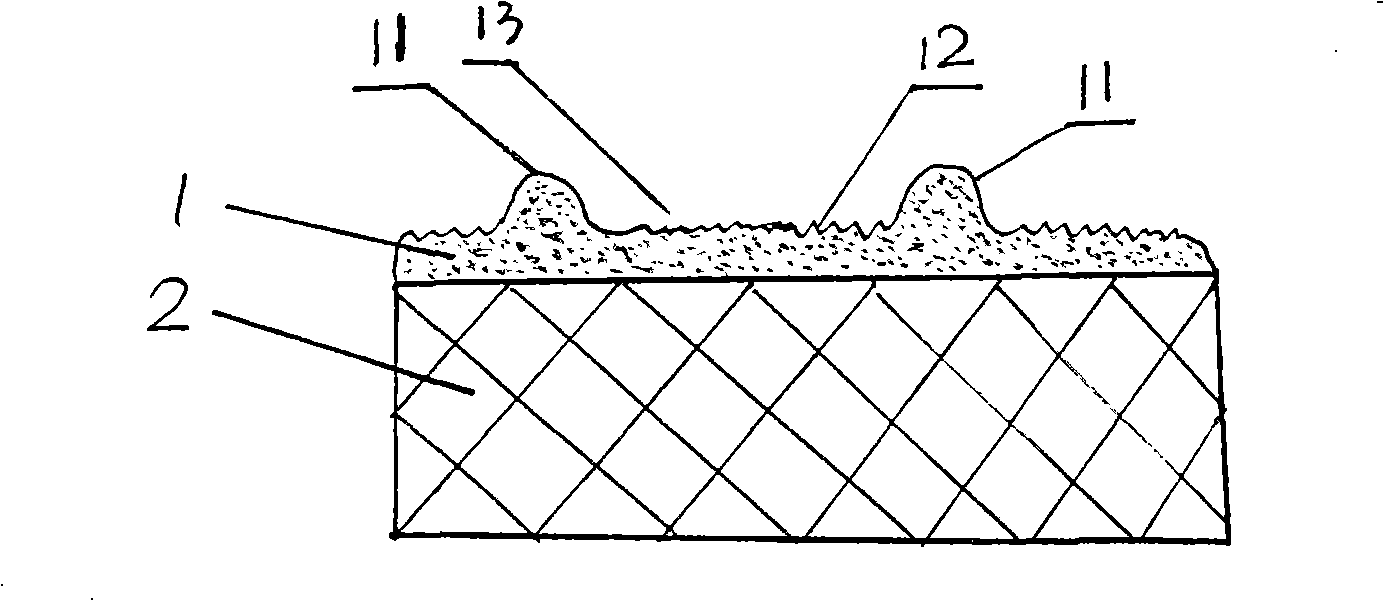

[0019] a. Use a 150-mesh screen to print the UV oil layer 1 on the gold cardboard sheet as the substrate 2; b. Send the gold cardboard sheet 2 into the first ultraviolet lamp box, and use a UV lamp with a power of 150W for the first UV light box. Once the sheet substrate is irradiated, the distance between the sheet substrate and the ultraviolet lamp is controlled between 5cm, and the transmission speed of the sheet substrate in front of the ultraviolet lamp is controlled at 40 m / min; c, the sheet substrate is from 2 seconds after the first UV light box is sent out, the sheet substrate is sent into the second UV light box, and another UV lamp with a power of 150W is used to irradiate the sheet substrate for the second time. The sheet substrate and the UV lamp The distance between them is controlled between 5cm, and the transmission speed of the sheet substrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com