Detection device

A technology for testing equipment and racks, applied in the field of machinery, can solve the problems of inability to meet the rhythm, slow completion, low work efficiency, etc., to improve work efficiency, reduce inventory, and prevent car ceiling configuration judgment and missing installations The effect of wrong installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

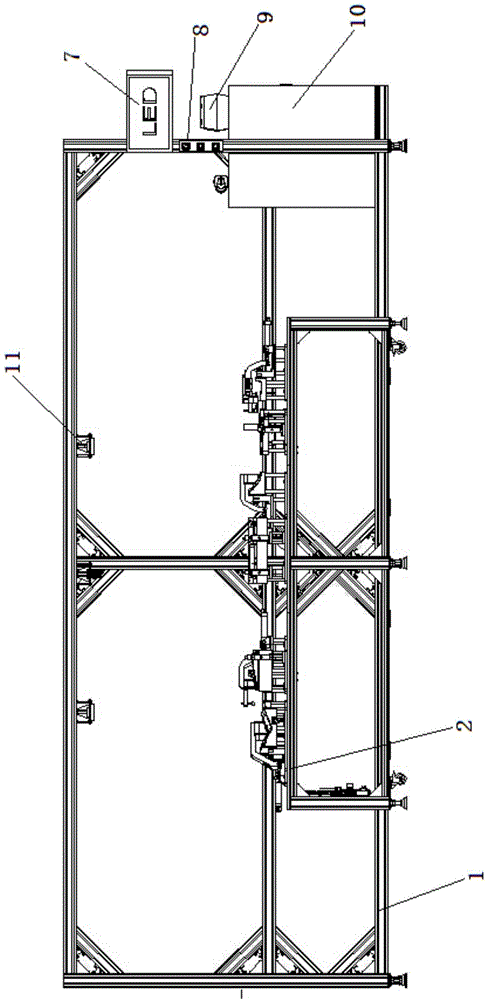

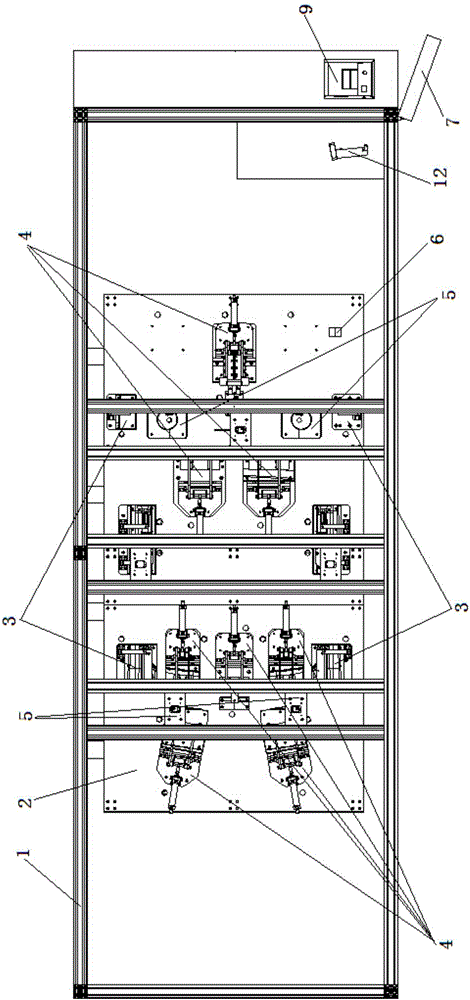

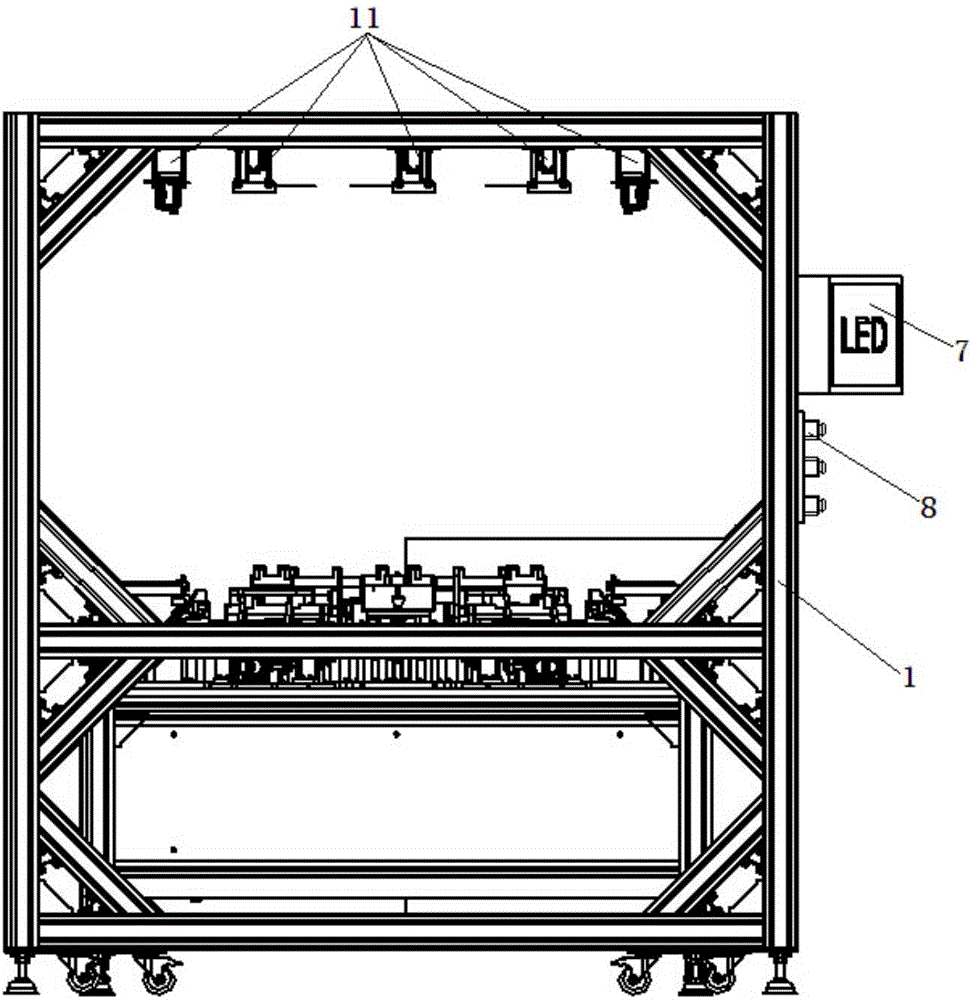

[0028] The present invention will be further described below according to the accompanying drawings.

[0029] like Figure 1 to Figure 3 As shown, the middle part of the frame 1 is provided with a table panel 2, and the left and right sides on the table panel 2 are respectively provided with a horizontal pen-shaped cylinder 4, and the front and rear sides of the horizontal pen-shaped cylinder 4 are respectively provided with a rotary compression cylinder 3; A color sensor 5 is provided between the horizontal pen-shaped cylinder 4 and the rotary compression cylinder 3; a camera 11 is provided on the frame 1 above the table top 2;

[0030] One side of the frame 1 is connected with an LED display 7, and the frame 1 below the LED display 7 is provided with an industrial control electromechanical box 10, and the upper part of the industrial control electromechanical box 10 is provided with a barcode printer 9 and a scanning gun 12; 7 and the frame 1 between the industrial control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com