Control method of safe stock control system

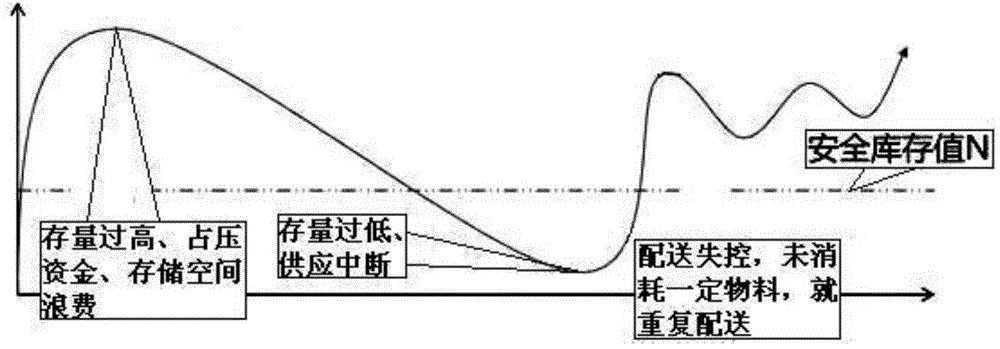

A safety stock and control system technology, applied in instruments, data processing applications, logistics, etc., can solve problems such as large errors in calculation methods, waste, and backlog of funds, and achieve the goal of reducing inventory occupancy costs, reducing inventory backlog, and speeding up inventory turnover. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

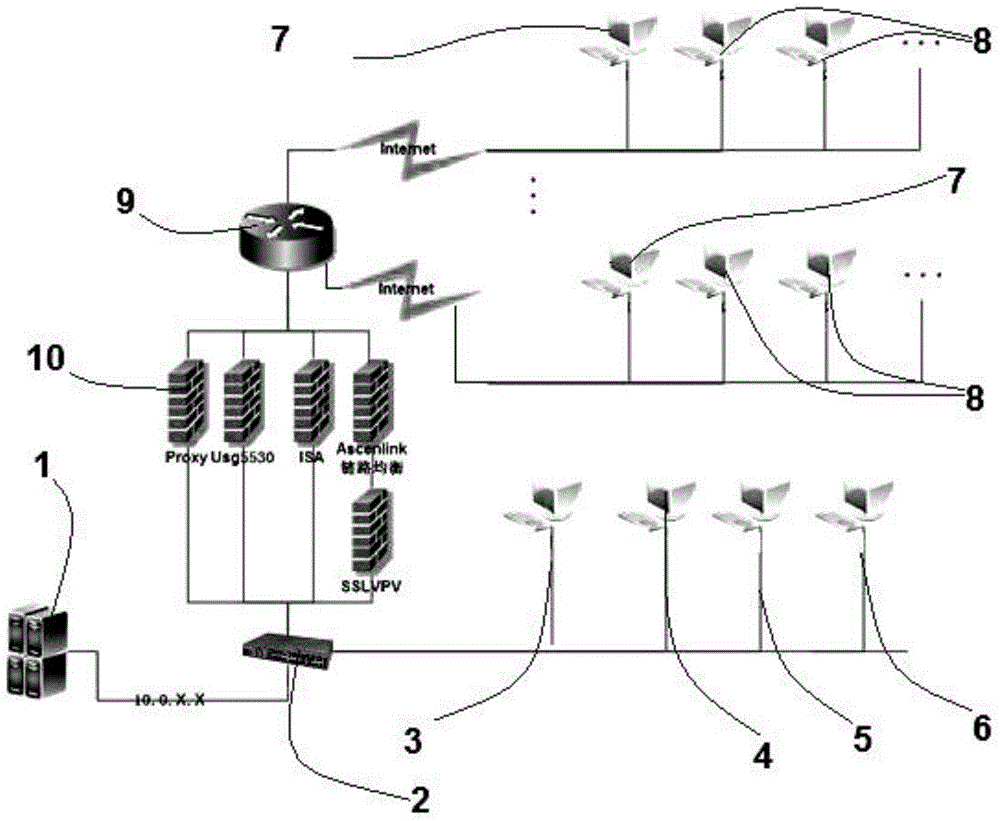

[0050] Such as figure 1The illustrated embodiment is a control method for a safety stock control system. The control system includes a server 1, a switch 2, a distribution computer 3, a spare parts planning computer 4, a warehouse computer 5, and a supervisory computer 6 located at the headquarters; Provincial material management computer 7, office computers 8 located in various offices in the province; switches are electrically connected to servers, distribution computers, spare parts planning computers, warehouse computers and supervisory computers, and switches are respectively connected to each provincial material management computer through the Internet and office computer connection; figure 1 Among them, a router 9 and a firewall 10 are also included.

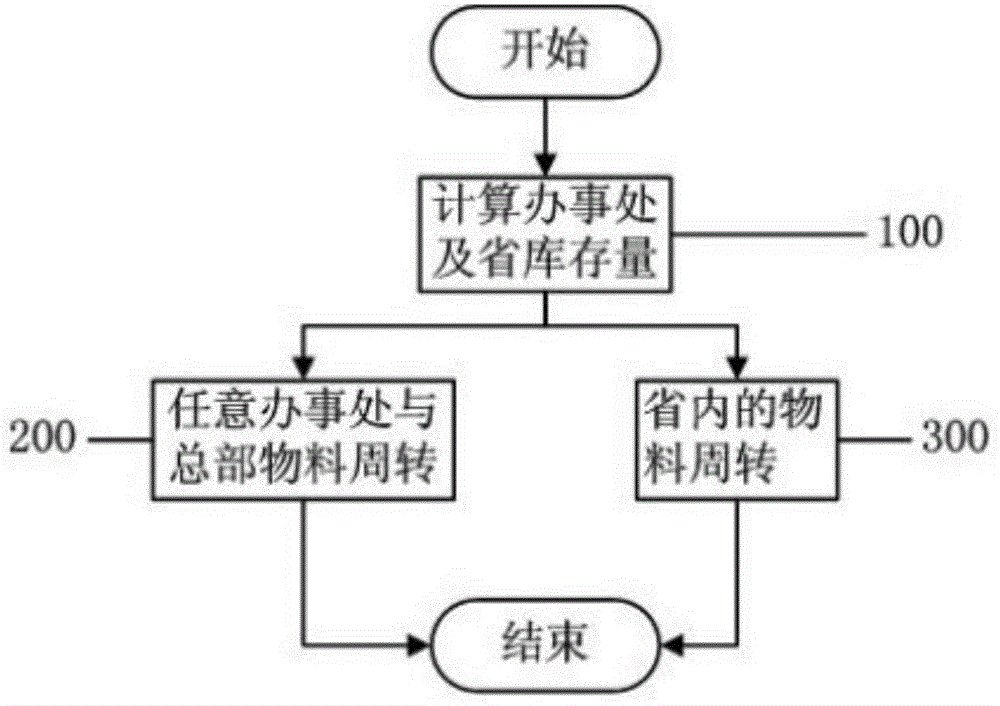

[0051] Such as figure 2 As shown, the control method includes the following steps:

[0052] Step 100, calculate office and provincial inventory:

[0053] The server is equipped with the formula for calculating the ...

Embodiment 2

[0079] If a material has a failure rate value greater than 3 months in the material turnover information database, the failure rate of the current month where y 1 、y 2 、y 3 are the failure rates for the first three months of the current month, respectively.

[0080] The benefits of using the failure rates of the previous three months to calculate the failure rate for this month are:

[0081] 1. Reduce accidental errors, the longer the calculation period, the more accurate the failure rate calculation;

[0082] 2. Reflect the trend of recent failure rate changes;

[0083] 3. It can be realized by every enterprise and has strong operability.

[0084] Other structures and steps of Embodiment 2 are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com