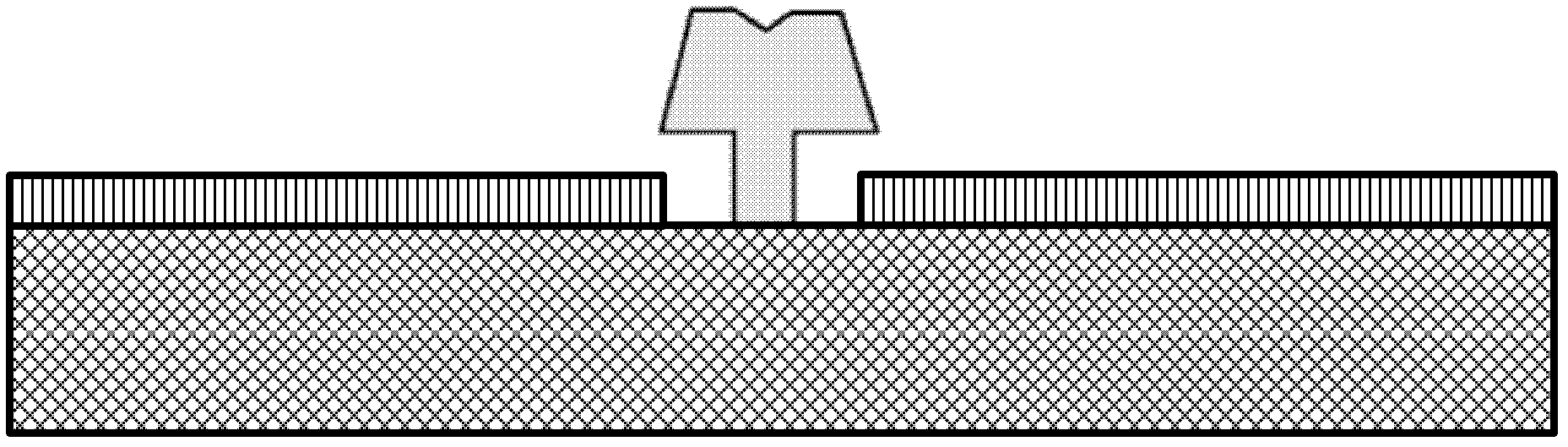

Method for manufacturing T-shaped gate by adopting single electron beam exposure

A technology of electron beam exposure and electron beam glue, which is applied in the field of preparing T-shaped grids by single electron beam exposure, can solve the problems of alignment error, high time and cost, and high cost per unit time of two exposures, and achieve a reduction in machine Occupying cost and reducing writing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

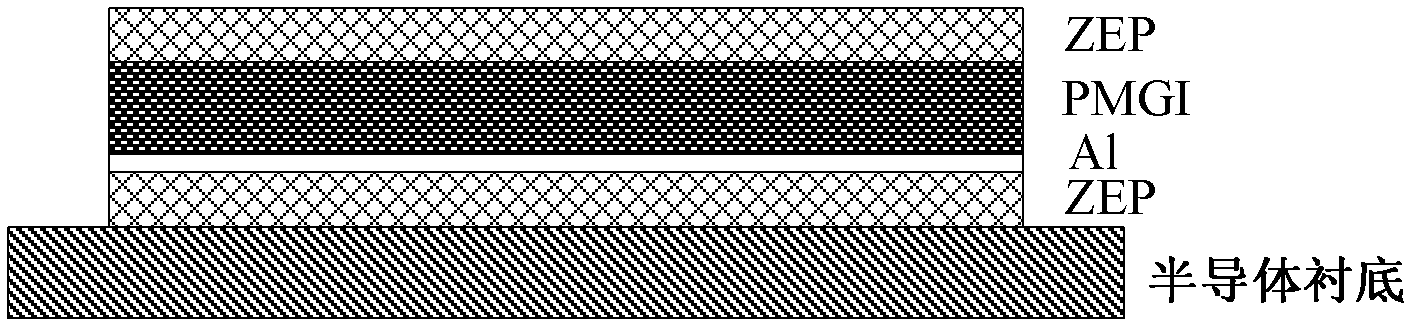

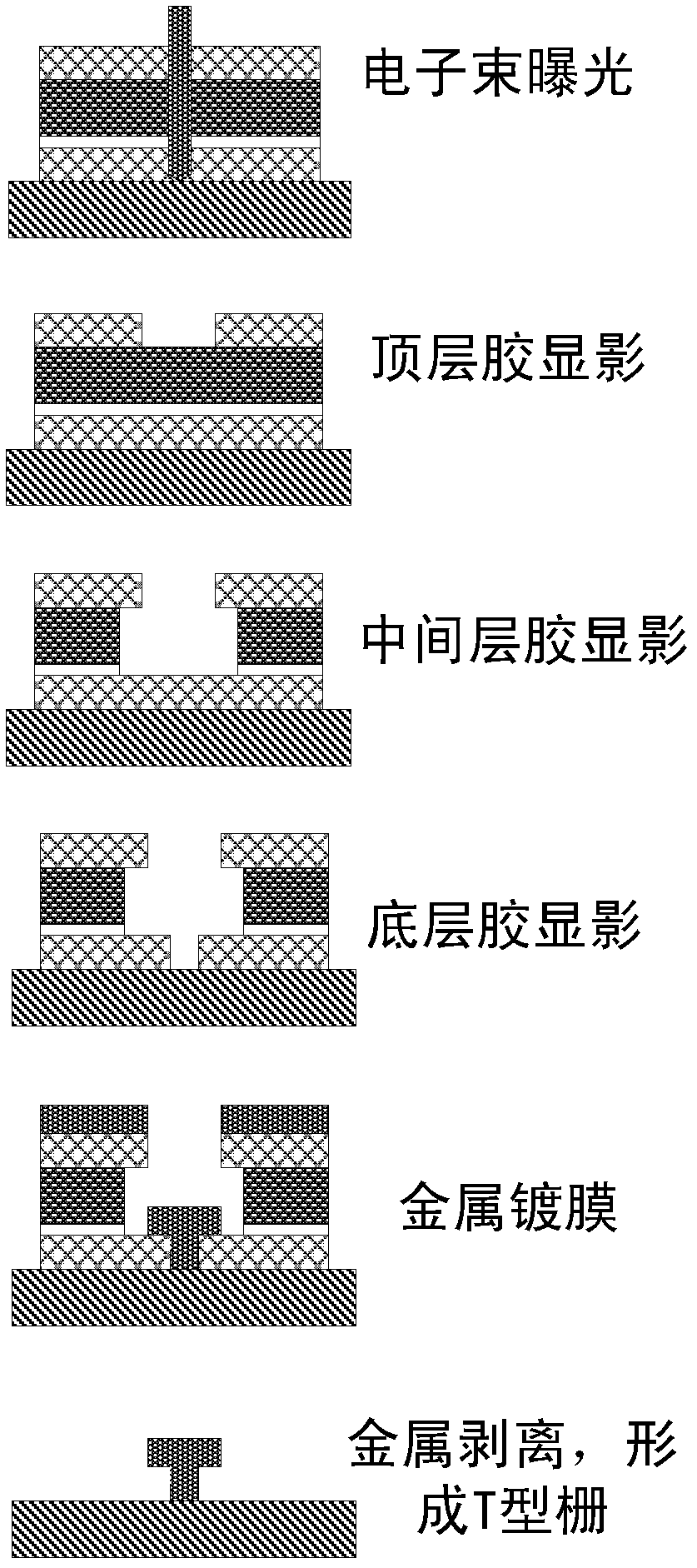

[0024] The method for preparing a T-shaped grid by using a single electron beam exposure provided by the present invention adopts a four-layer laminated glue, only needs to expose the grid pin pattern once, and through multiple layers of development, the grid cap and grid cap can be formed. Graphics required for grid pins.

[0025] The lamination glue structure that the present invention adopts is as figure 2 As shown, it is divided into 4 layers from bottom to top, which are the bottom electron beam glue ZEP, metal aluminum (Al), electron beam glue PMGI and the top electron beam glue ZEP, among which:

[0026] The bottom electron beam glue ZEP is formed on the semiconductor substrate, and its thickness is selected to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com