Control method for a gas turbine blade forging stock geometry and testing model

A gas turbine blade and geometric dimension technology, which is applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems that the actual shape of the blade cannot be accurately reflected, it is difficult to guarantee the machining allowance, and the geometric dimension is difficult to detect, so as to achieve light weight and labor-intensive operation. The effect of low strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, a method for controlling the geometric dimensions of a gas turbine blade forging blank, including the steps of sample making and comparative inspection, the sample making consists of the steps of section sample making, axis sample making, and sample combination;

[0049] The making of the section template includes:

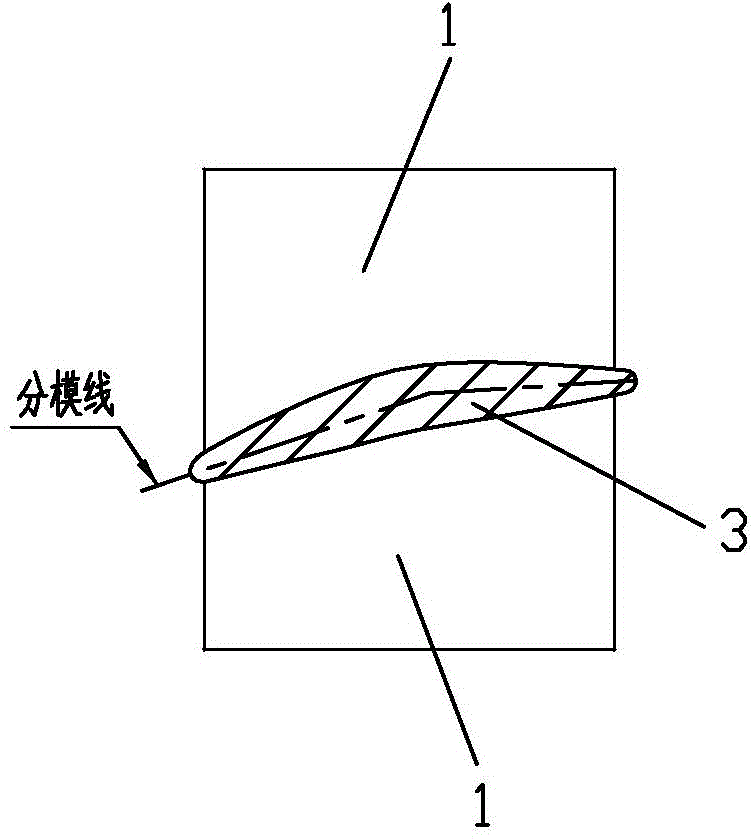

[0050] The first step, in the figure 1 and figure 2 In the three-dimensional model of the blade forging blank shown, the blade is cut transversely along the set distance in the axial direction to form a image 3 The two-dimensional graphic of the transverse section, and record the coordinate origin data and the cutting position data;

[0051] The second step is to export the cross-sectional two-dimensional drawing as a CAD format file;

[0052] The third step is to divide the two-dimensional graphics of the section according to the position of the parting line in CAD, and use the part of the continuous contour line of the section on the in...

Embodiment 2

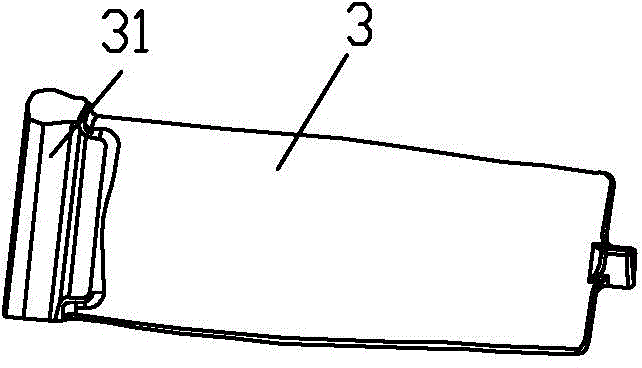

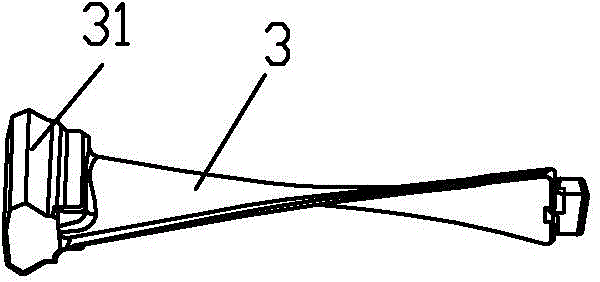

[0067] Embodiment 2, a gas turbine blade forging billet geometric dimension detection template, including a cross-section template 1, the cross-section template 1 is used for comparative detection in the width direction of the inner arc surface or outer arc surface of the set position on the blade length, and is characterized in that, There are multiple cross-section templates 1, and multiple cross-section templates 1 are used to compare and detect the lateral contours of multiple set positions on the same arc surface of the blade. Multiple cross-section templates 1 are connected in series by the same axis template 2 to form a fishbone shape. The axis template 2 is used for comparative detection of the longitudinal profile on the arc surface of the blade corresponding to the section template 1; the comparative detection edges on the section template 1 and the axis template 2 are in the shape of a blade.

[0068] The axis template 2 is formed with a longitudinal positioning stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com