Steel coil stock control method based on crane positioning system

An inventory control and positioning system technology, applied in instruments, measuring devices, data processing applications, etc., can solve the problem that the coil position information and coil conditions cannot be determined in real time, and the coil warehouse management system has no optimization function and cannot be very efficient. Good realization of logistics management and other issues, to achieve the effect of automation of operations, improvement of functions, and reduction of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

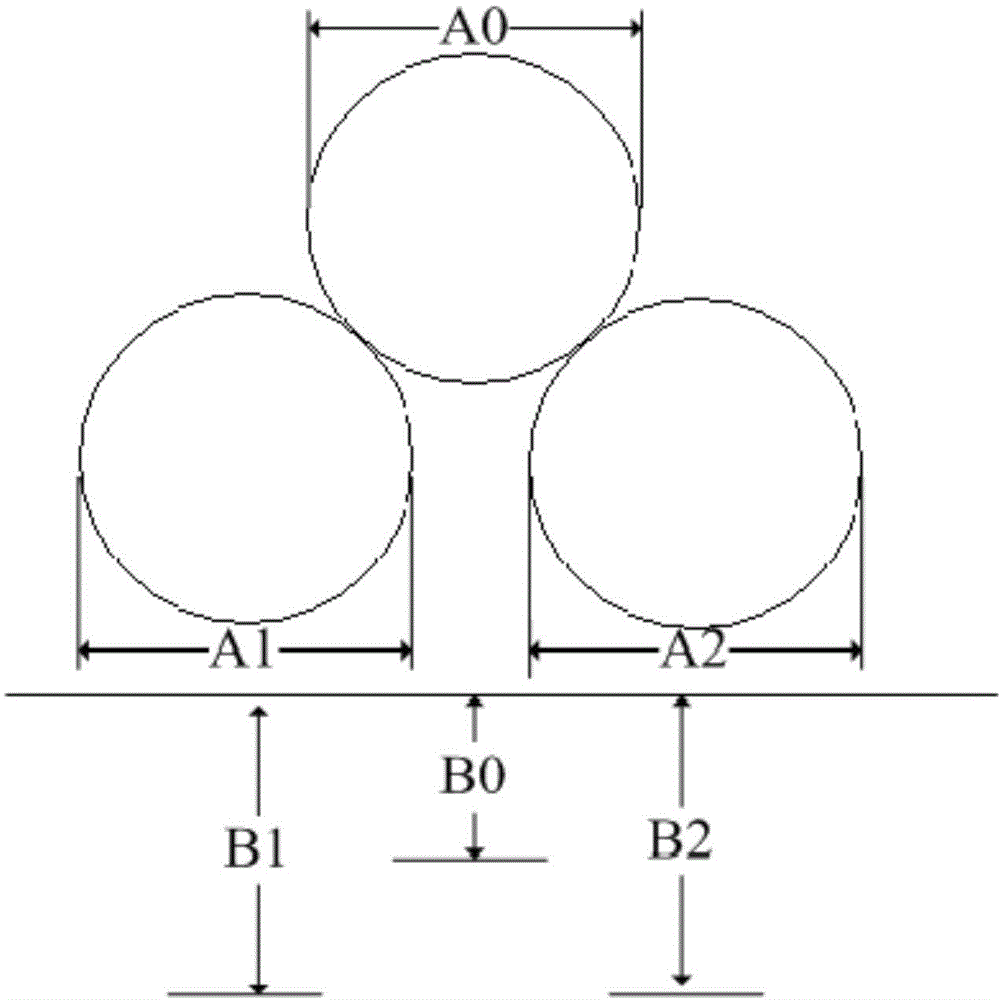

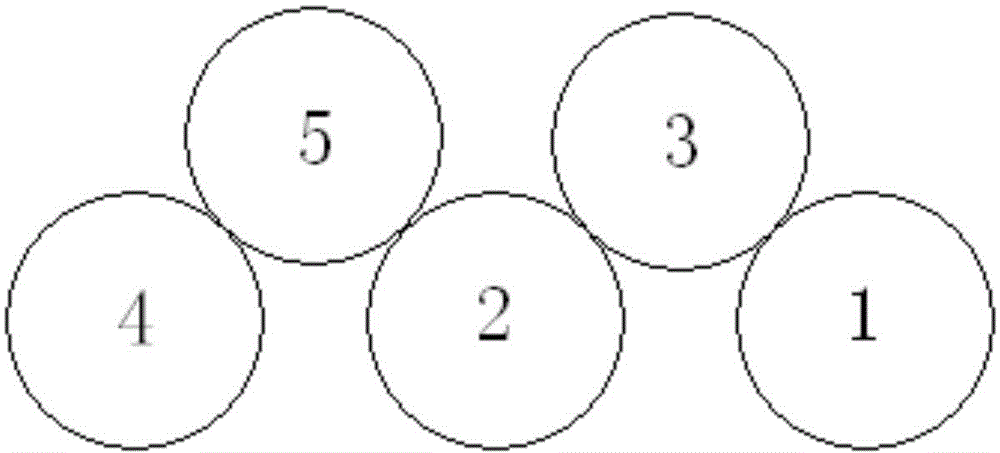

[0079] The specific content and steps of the steel coil inventory control method based on the crane positioning system of the present invention are:

[0080] 1. Install the crane laser positioning system-level transportation chain tracking and positioning system to coordinate the storage location in the steel coil warehouse and the rolling line transportation chain, and establish the storage location tracking for each steel coil.

[0081] 2. Use laser measurement technology to detect the running coordinates of the crane, combine the coordinate information with the crane operation command, display them together on the vehicle terminal, and transmit the results of the crane operator's operation to the coil warehouse management system in real time.

[0082] 3. Tracking of the transportation chain The running position of the steel coils in the transportation chain is tracked until the steel coils come off the assembly line and enter the steel coil warehouse; the steel coil warehous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com