Bottom discharge method and bottom discharge device for light calcium carbonate calcining furnace

A light calcium carbonate, discharge device technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problem of poor working environment, high labor intensity, prone to accidents, etc. problem, to achieve the effect of saving manpower, reducing labor intensity and avoiding injury accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

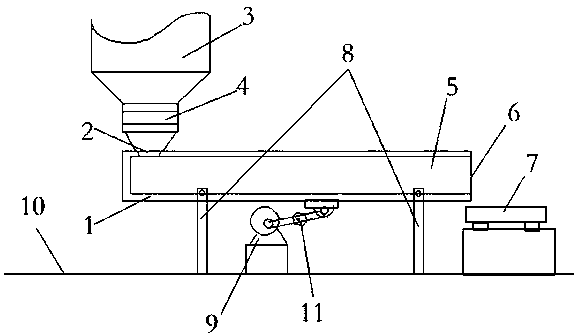

[0030] as attached figure 1 Shown, a kind of discharge device at the bottom of the light calcium carbonate calciner is a vibrating type discharging device, and the vibrating type discharging device 5 comprises a vibrating pipeline 1, and there is a feed inlet 2 of a vibrating type discharging device on the vibrating pipeline 1; Simultaneously, an movable connection sleeve 4 is installed at the discharge port of the lower part of the vertical calciner 3, the upper end of the movable connection sleeve 4 is connected to the lower discharge port of the calciner, and the lower part is connected to the feed port 2 of a vibrating discharge device. Above; the vibrating discharge device 5 lies below the discharge port at the bottom of the calciner 3, and is a vibrating pipeline discharge device. On the movable connection sleeve 4, the discharge port 6 of the vibratory discharge device is located above the calcined material conveyor belt 7; The discharge port 6 of the vibrating dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com