Production equipment for stranded welding wire structure

A technology of stranded welding wire and production equipment, which is applied in the field of production equipment of stranded welding wire structure, which can solve the problems of difficult coiling, high energy consumption, poor rigidity, etc., and achieve high production efficiency, low investment cost and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

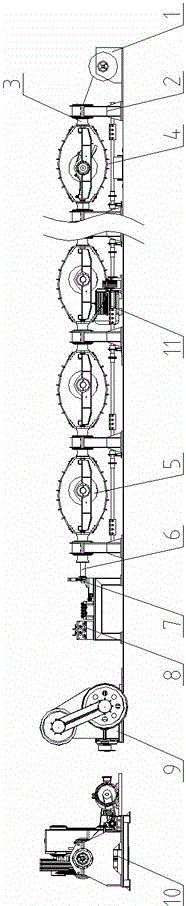

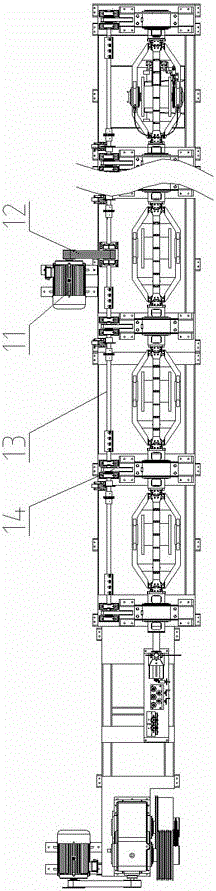

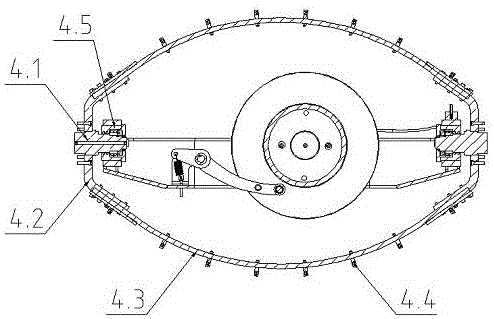

[0045] see Figure 1~Figure 4 , the present invention is a kind of production equipment of stranded welding wire structure, and it comprises the outer pay-off stand 1 that arranges from back to front successively, a plurality of bearing seat devices 2, crimping device 7, straightening device 8, traction device 9 and take-up The wire device 10, the plurality of bearing seat devices 2 are provided with hollow shafts 3, and the bow winch ship 4 is arranged between two adjacent hollow shafts 3, and the bow drawer ship 4 is provided with an I-shaped wheel Assemblies 5, a coupling transmission shaft 13 is provided under the plurality of bearing seat devices 2, and a motor 11 is provided outside the coupling transmission shaft 13, and the motor 11 and the coupling transmission shaft 13 are connected through a first transmission mechanism 12 , the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com