Oil-filter of building machine and its assembling method

一种建筑机械、滤油器的技术,应用在化学仪器和方法、建筑、膜过滤器等方向,能够解决增加制造成本、储存间空间效率降低、发货状况产生偏差等问题,达到提高整体寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

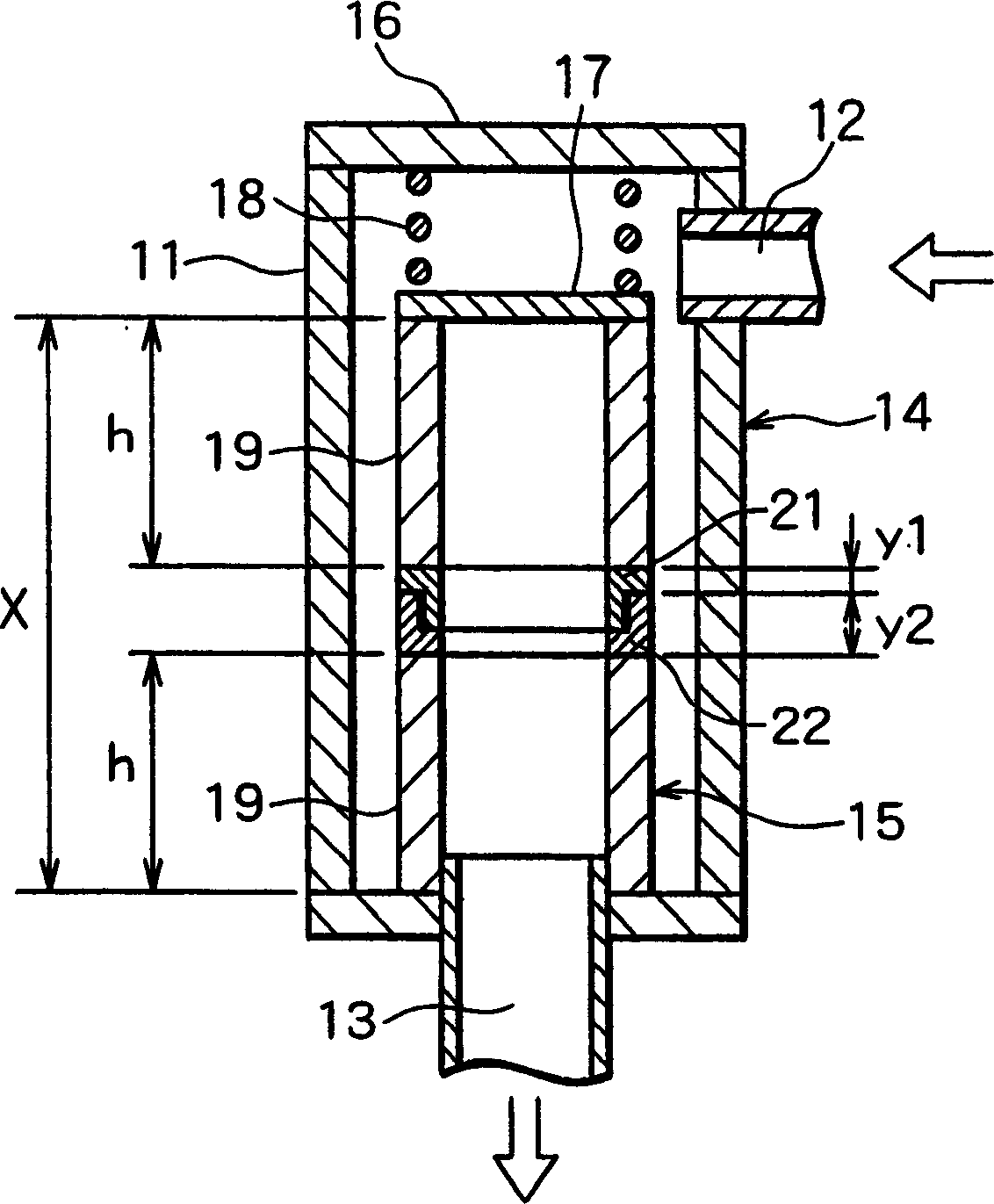

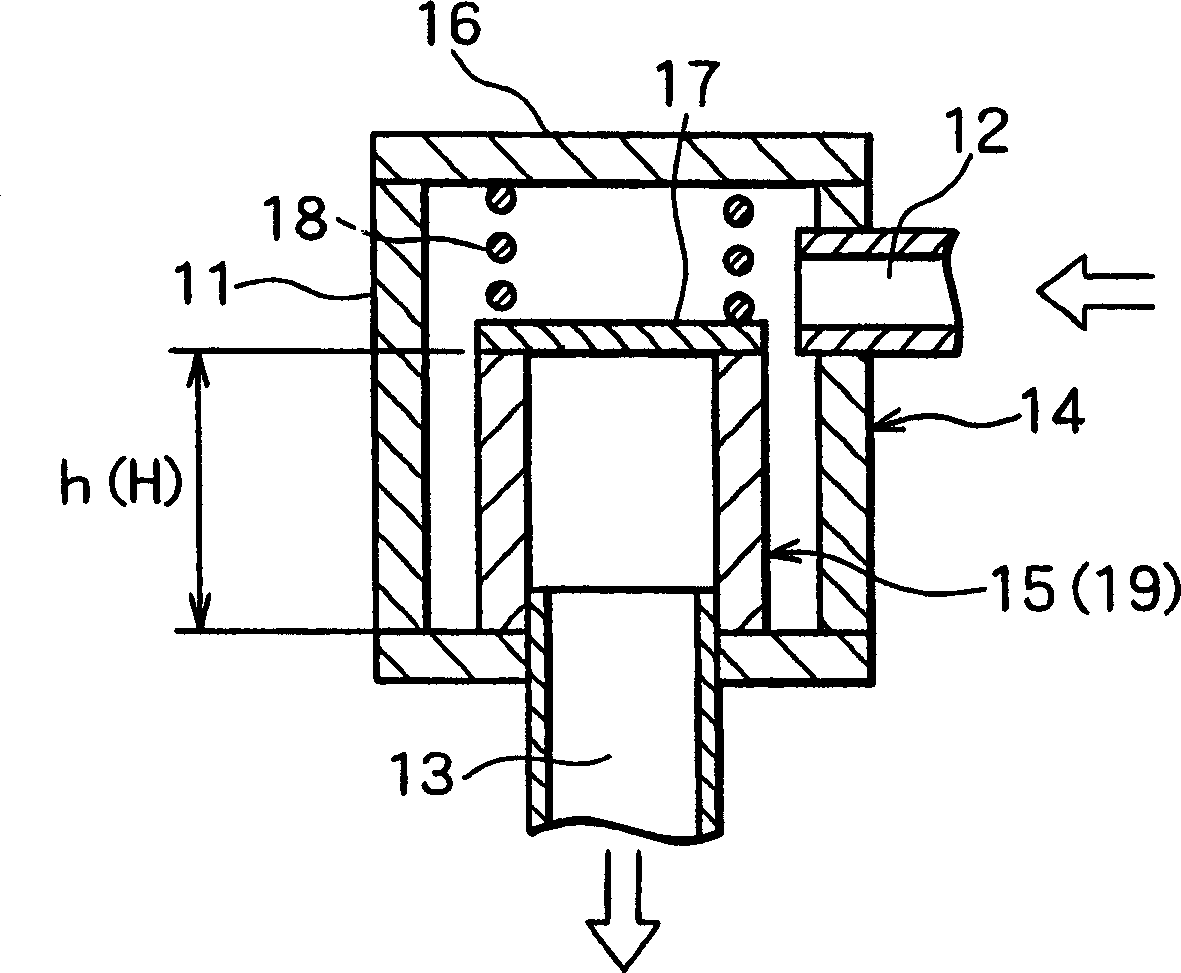

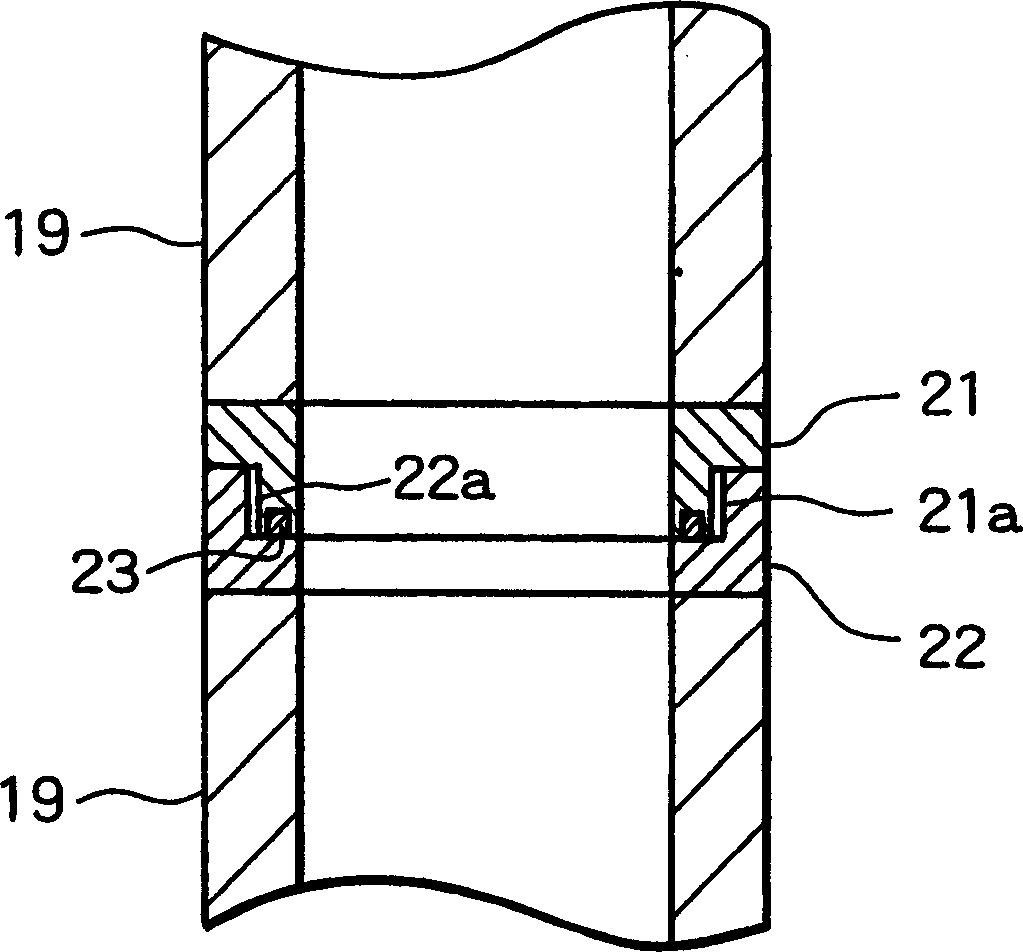

[0016] Embodiment 1 (with reference to Figure 1-3 )

[0017] exist figure 1 and 2 Among them, the oil filter of Example 1 was constructed as follows. The housing 14 is formed, and the metal cylindrical container 11 is provided with an oil inflow port 12 on the side wall and an oil outflow port 13 in the bottom wall. A filter element 15 made of cellulose fibers, glass fibers or the like is accommodated in the housing 14 as a filter element. The filter element 15 is arranged such that its outer peripheral surface is on the oil inflow side and its inner peripheral surface is on the oil outflow side. The oil filtered and purified by the filter element 15 is discharged through the oil outlet 13 provided at the bottom of the casing 14 and returned to the oil sump. Such as figure 1 As shown, the element 15 is configured to cover the oil outlet 13 .

[0018] In addition, although the shape of this element 15 is cylindrical and cylindrical in illustration, it is not limited to ...

Embodiment 2

[0036] Embodiment 2 (with reference to Figure 5 ,Figure 6)

[0037] In Example 2, the same parts as those in Example 1 are denoted by the same symbols, and repeated description thereof will be omitted.

[0038] In Embodiment 1, the effective height dimension H of the filter element 15 can be adjusted to an integer multiple of the height dimension h of the element block 19 . In the case where it is necessary to further expand the range of size adjustment according to the flow rate of oil, Embodiment 2 is suitable.

[0039] In Example 2, such as Figure 5 As shown, the filter element 15 is formed by combining two types of element blocks 19A and 19B having different height dimensions ( h1 , h2 ) in an appropriate number (one each in the drawing). Among them, element block 19A is a small block, and 19B is a large block longer than 19A.

[0040] In this case, as shown in FIGS. 6A-6E , filter elements of various sizes can be configured using only two types of element blocks 19A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com